Thermal cracking gasification oven for city domestic garbage

A technology for incineration of domestic waste and domestic waste, which is applied in the field of thermal cracking and gasification treatment of urban domestic waste, and can solve the problems of high charge selectivity, high price, and insignificant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

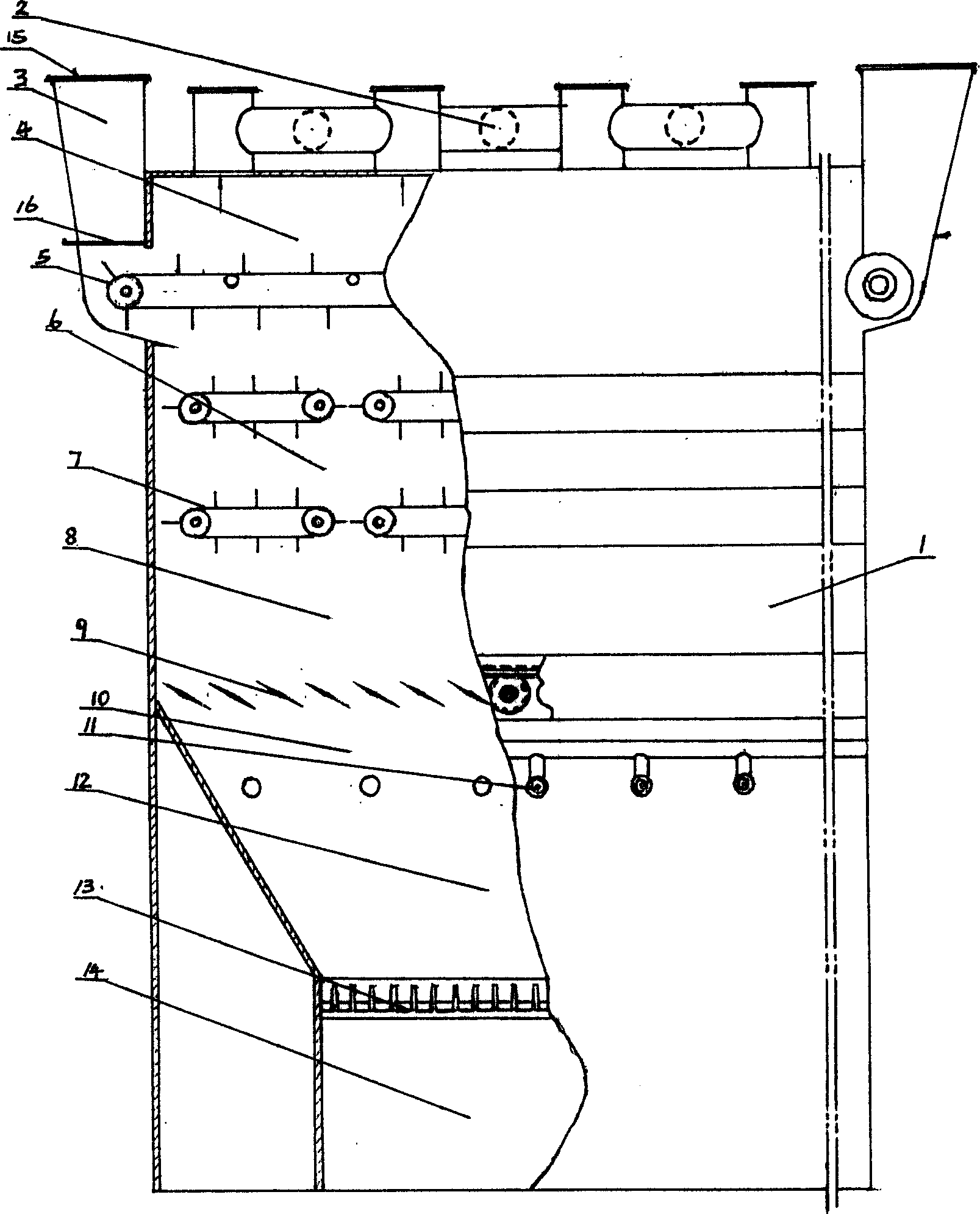

[0006] Rectangular furnace body 1 is composed of 8 main structural parts, which are: furnace gas outlet pipe assembly 2, feeding bin 3, rectangular negative pressure bin 4, rectangular drying chamber 6, rectangular gasification chamber 8, gas return booster The height and width of the thermal combustion chamber 10, the melting combustion chamber 12, the slag bin 14, and the rectangular body of furnace 1 are basically fixed values, while the size in the longitudinal direction can be selected in a wide range according to the actual requirements of customers.

[0007] After the charge enters the feed bin 3, the top cover 15 located above the feed bin 3 is closed, the drag door 16 located under the feed bin 3 is opened, and the charge is sent into the rectangular drying chamber 6 by the scraper type crawler 5. There are two feeding bins 3, which are respectively arranged on both sides of the upper part of the rectangular body of furnace 1. The scraper type crawler 5 can move forwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com