Switching magnetic valve

A technology for switching solenoid valves and solenoid armatures, applied in valve details, valve devices, control valves and air release valves, etc., can solve problems such as reducing efficiency, interfering with magnetic flux, and slow response time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

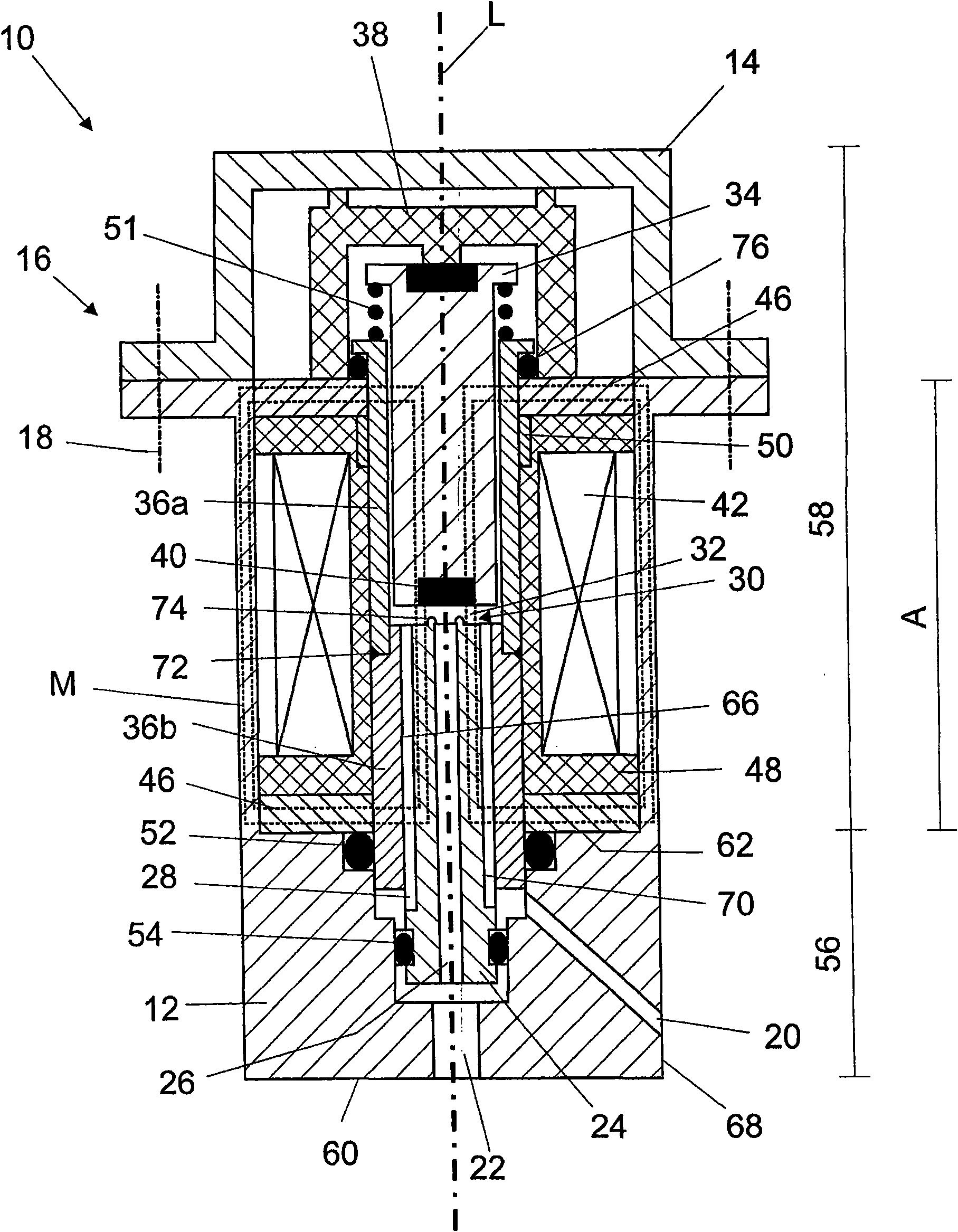

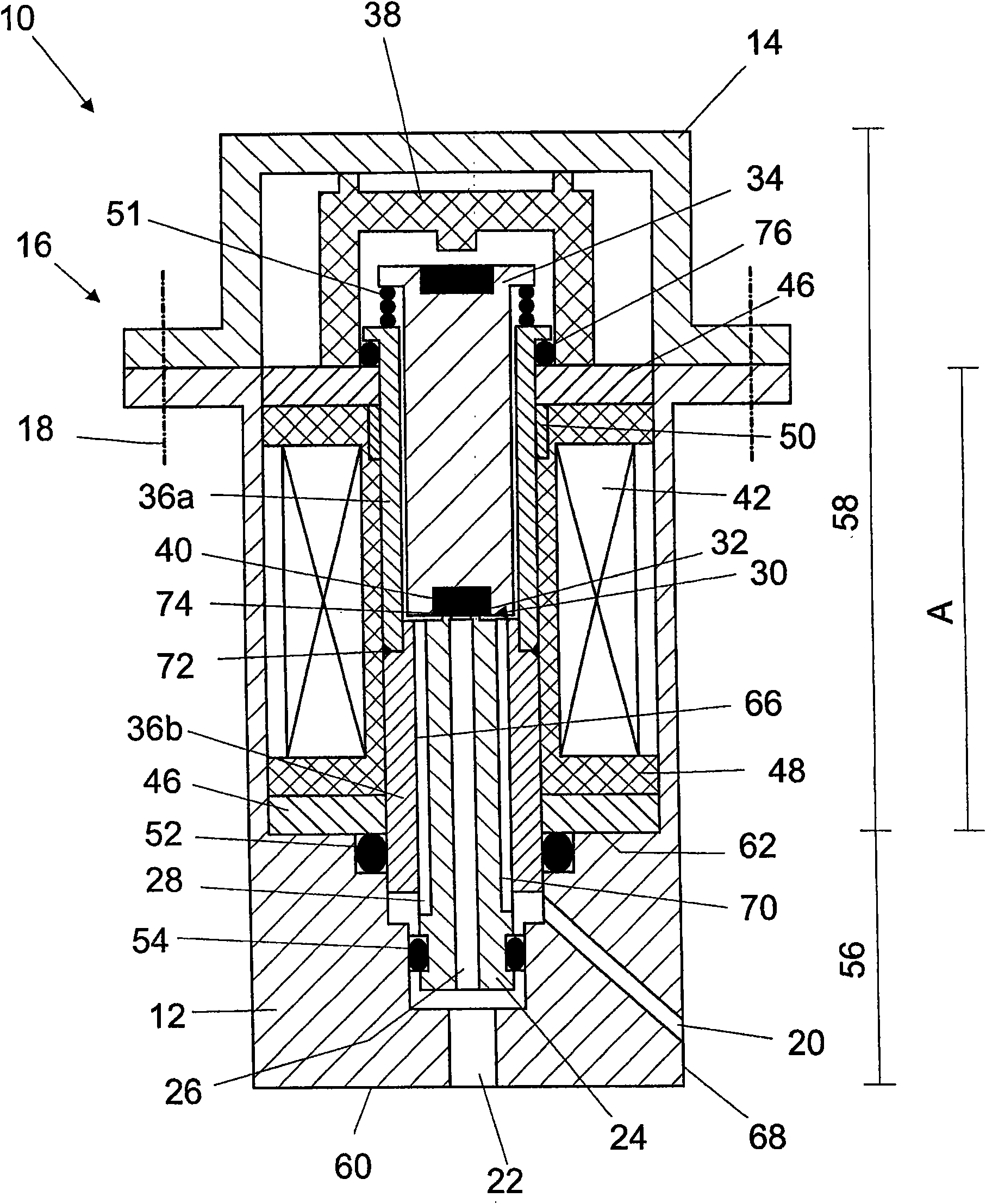

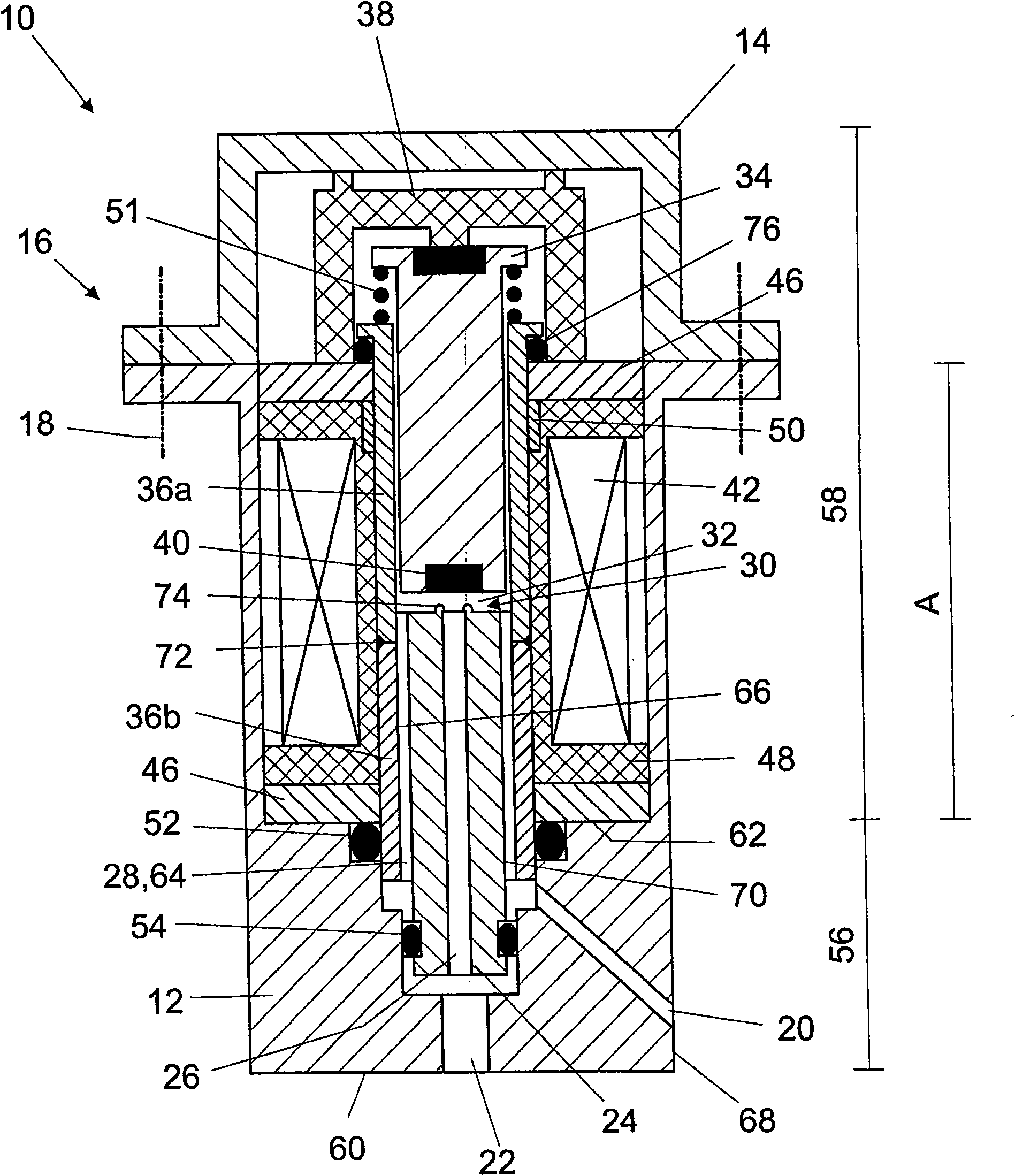

[0024] exist figure 1 and 2 The switching solenoid valve 10 shown in includes a housing 12 , preferably made of a magnetizable material such as iron, which can be selectively opened by means of a cover or bow 14 . In the example shown, the bracket 14 is connected to the housing 12 via a flange connection 16 , where screws 18 are used as fastening means. Other ways of fastening the bracket 14 to the housing 12 are also possible. The housing 12 has a first channel 20 and a second channel 22 for introducing compressed air into the interior of the switching solenoid valve 10 or leading compressed air out of the interior of the switching solenoid valve 10 . A valve core 24 is arranged inside the housing 12 , and the valve core 24 communicates with the first channel 20 and the second channel 22 . In addition, the valve element 24 has a bore 26 on which one or more gaps 28 are additionally located, which form a flow channel 28 through which compressed air can be directed in the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com