Method and device for detecting corrosion of component with permeability magnetic material protective layer

A corrosion detection and protective layer technology, applied in the field of non-destructive testing based on pulsed eddy current, can solve the problem of low sensitivity and achieve the effect of increasing penetration depth, improving detection sensitivity and reducing magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

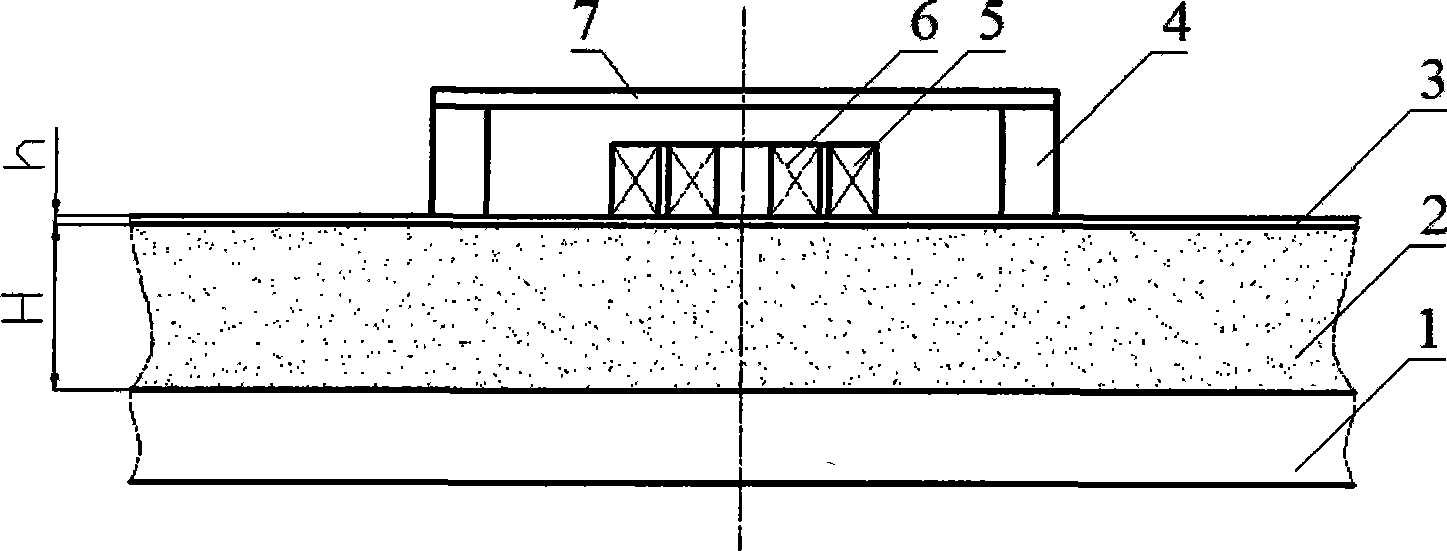

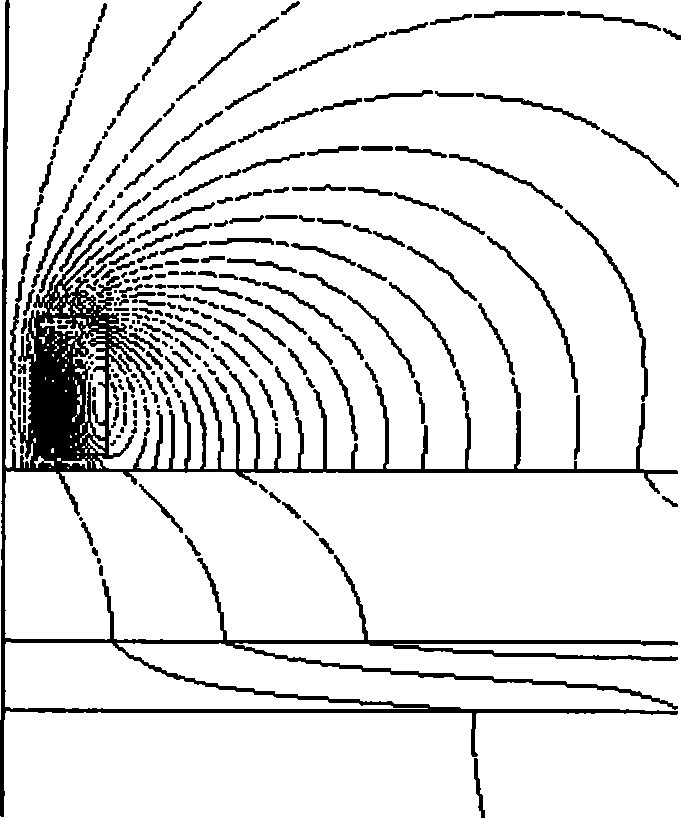

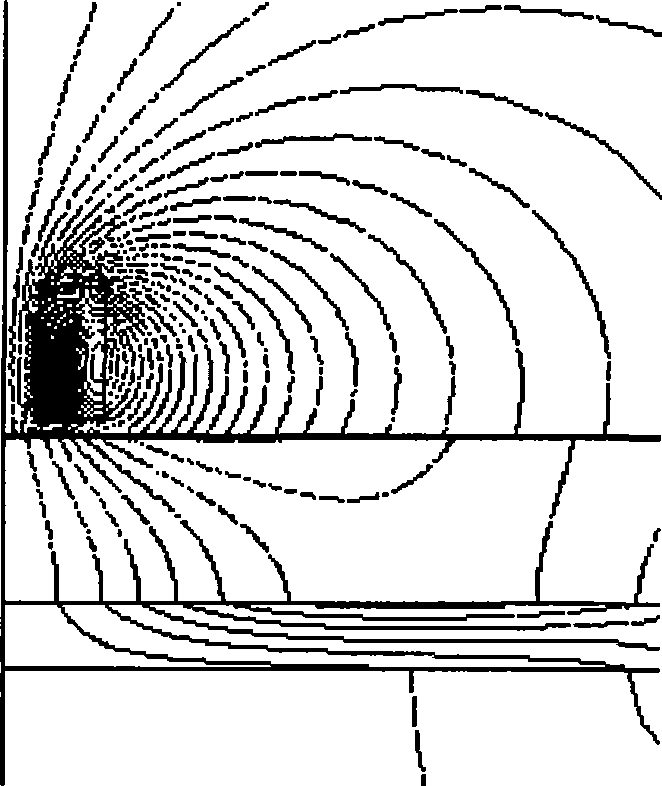

[0029] The principle schematic diagram of detection method of the present invention is as figure 1 As shown, the component under test 1 is covered with a cladding layer 2 with a thickness H, and the cladding layer 2 is covered with a magnetically permeable protective layer 3 with a thickness h. The upper end of the permanent magnet 4 is adsorbed on the left and right ends of the yoke 7, and the polarities of the magnets at both ends are perpendicular to the measured member 1 and opposite, and the lower end of the permanent magnet 4 is adsorbed (or lifted away from a certain distance) on the magnetic conductive protective layer 3, and the permanent magnet 4 , The magnetic yoke 7 and the magnetically conductive protective layer 3 form a closed magnetic path, which magnetizes the magnetically conductive protective layer 3 to deep saturation or deep saturation, reduces the magnetic permeability of the magnetically conductive protective layer material, and improves the penetration d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com