Construction process for reverse circulation pore-forming super-long large-diameter in-water cast-in-place pile

A construction technology and reverse circulation technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problem of difficulty in meeting the quality requirements of super long-diameter cast-in-place piles in water, insufficient verticality of pile positions, and unsatisfactory hole-forming quality, etc. problems, to achieve the effect of ensuring convenience and construction quality, improving drilling efficiency and reducing repeated crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

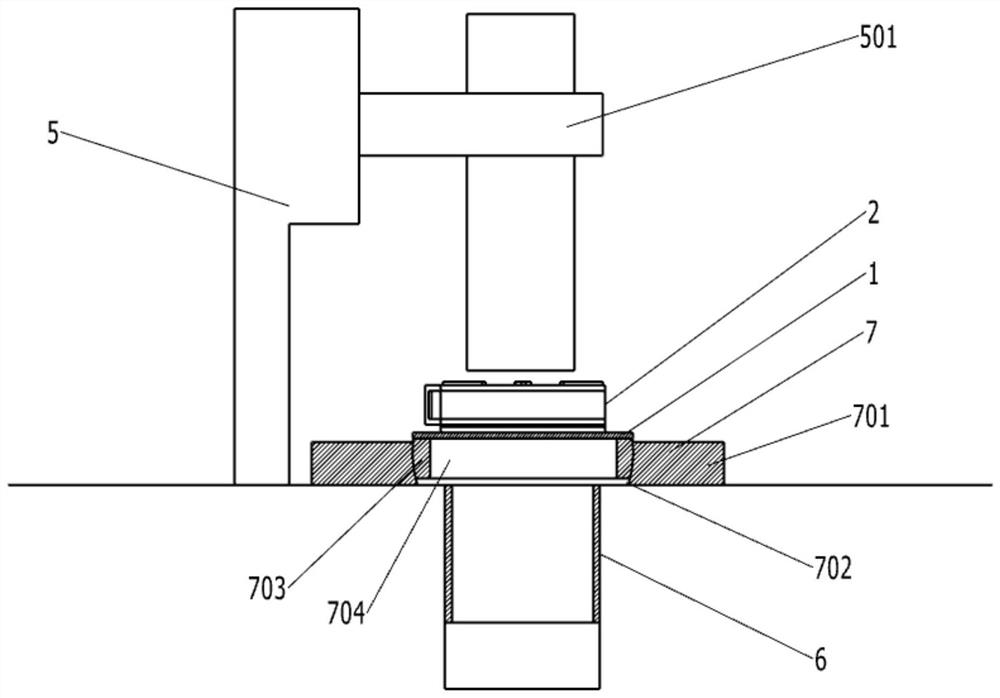

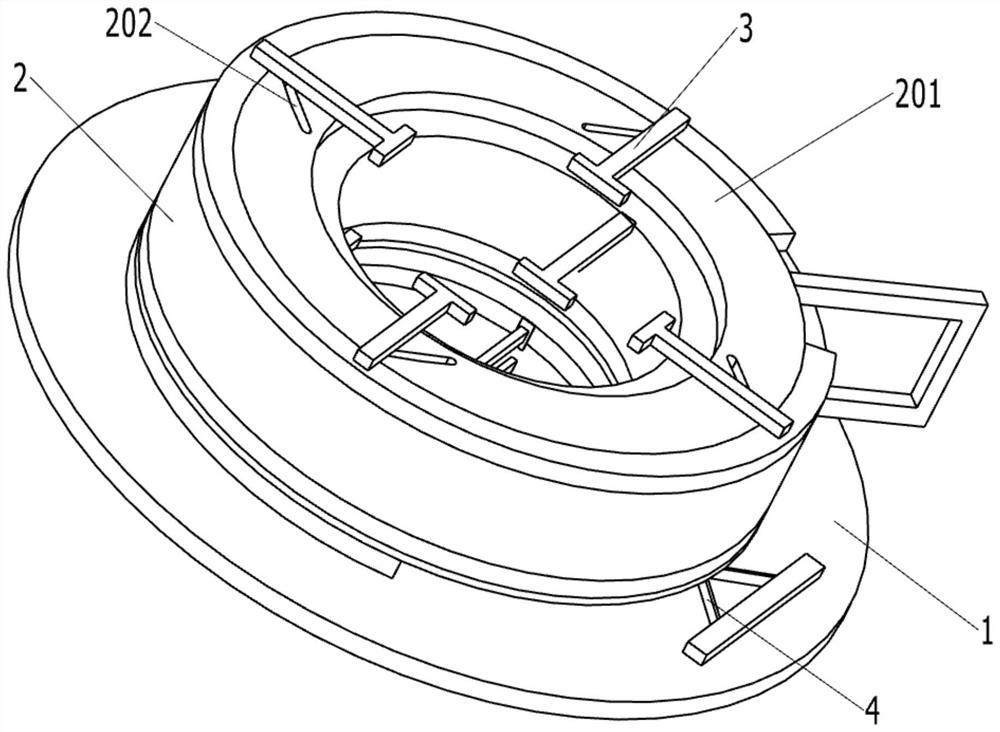

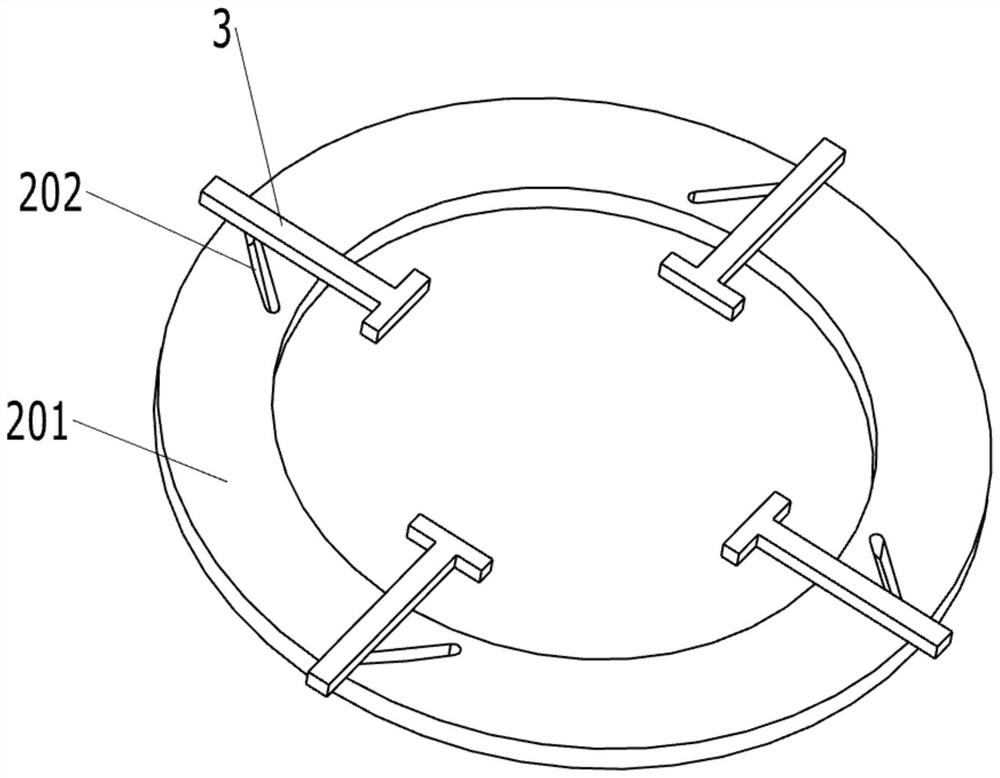

[0033] like Figure 1-5 As shown in the figure, the present invention provides a construction process for a reverse circulation pore-forming super-long diameter water cast-in-place pile, which includes the following steps: S1: measuring and setting out the pile position and then burying the guard pile; lowering the steel guard tube through a precise positioning device and detecting the verticality; The drilling rig (5) is in place; the mud is prepared by using bentonite, and the mud circulation device is used to form continuous circulating sedimentation and purification; and the mud performance indicators are monitored in real time;

[0034] S2: Move the drilling rig (5) so that the guiding mechanism (501) installed on the drilling rig (5) is axially coincident with the precise positioning device (1), and the drilling is carried out through the reverse circulation process. During the drilling process Check the hole diameter and the verticality of the hole in real time, check t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com