High-speed railway soft rock deep cutting arch-up deformation control structure and construction method

A high-speed railway and control structure technology, applied to roads, buildings, ballast layers, etc., can solve problems such as rework processing, overrun deformation during the operation period of the line, and accurate prediction of arch deformation, so as to reduce expansion pressure and deformation , Realize the effect of rock mass stress redistribution and strong control reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further elaborated below in conjunction with the accompanying drawings and examples.

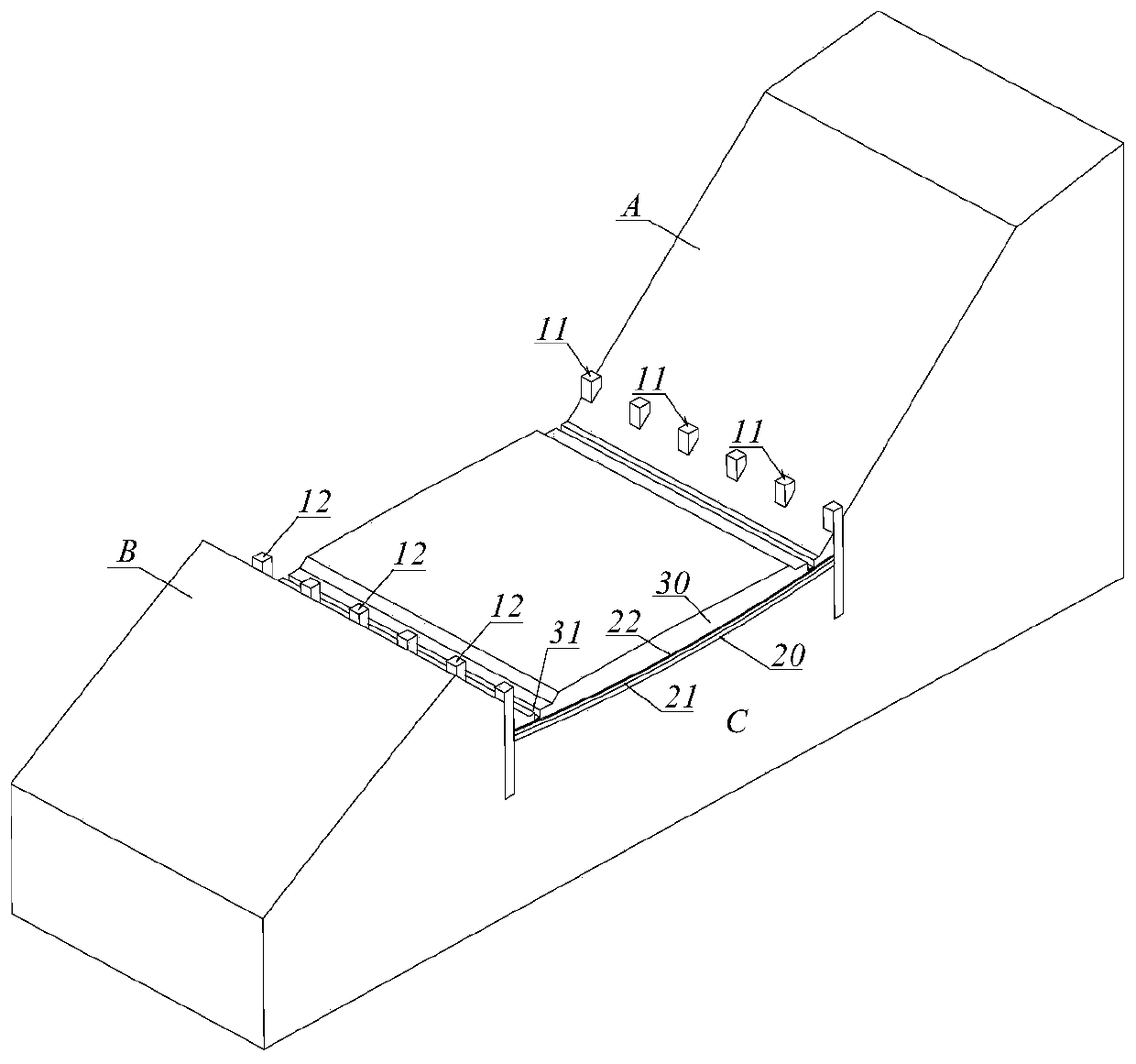

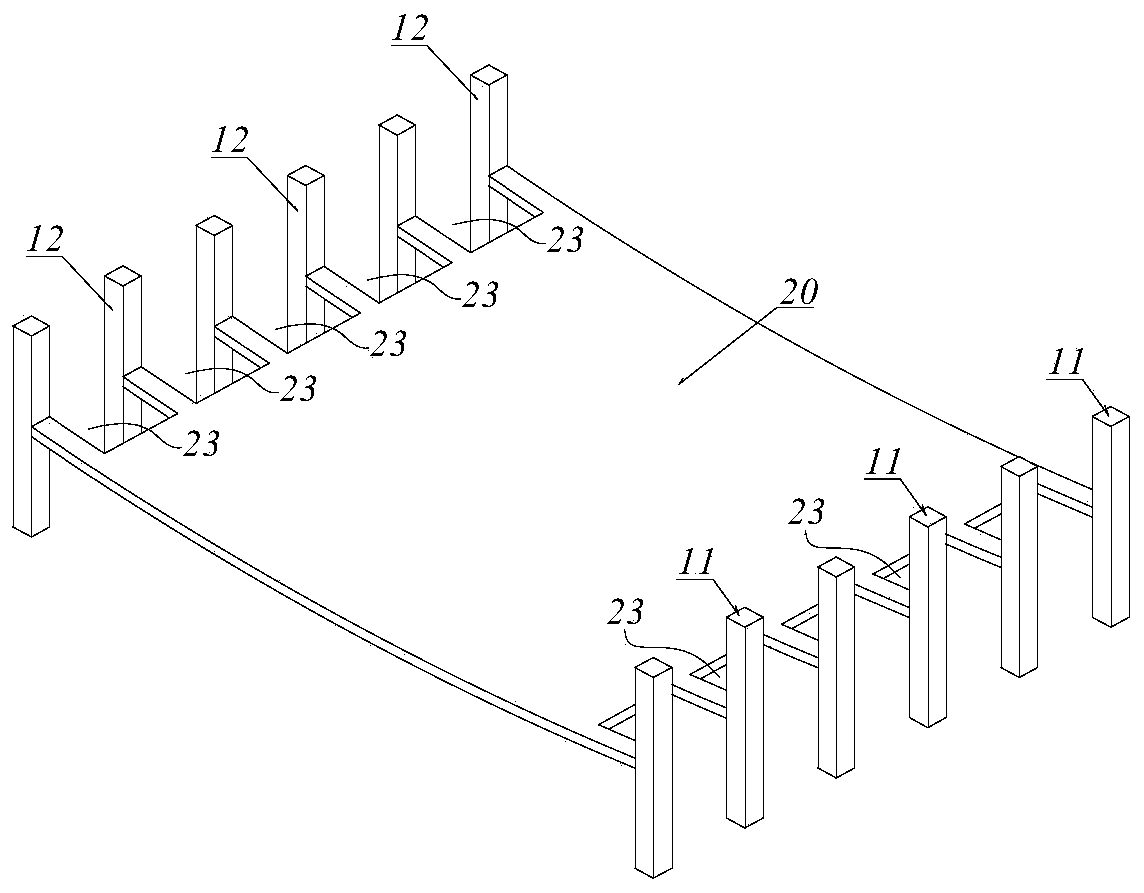

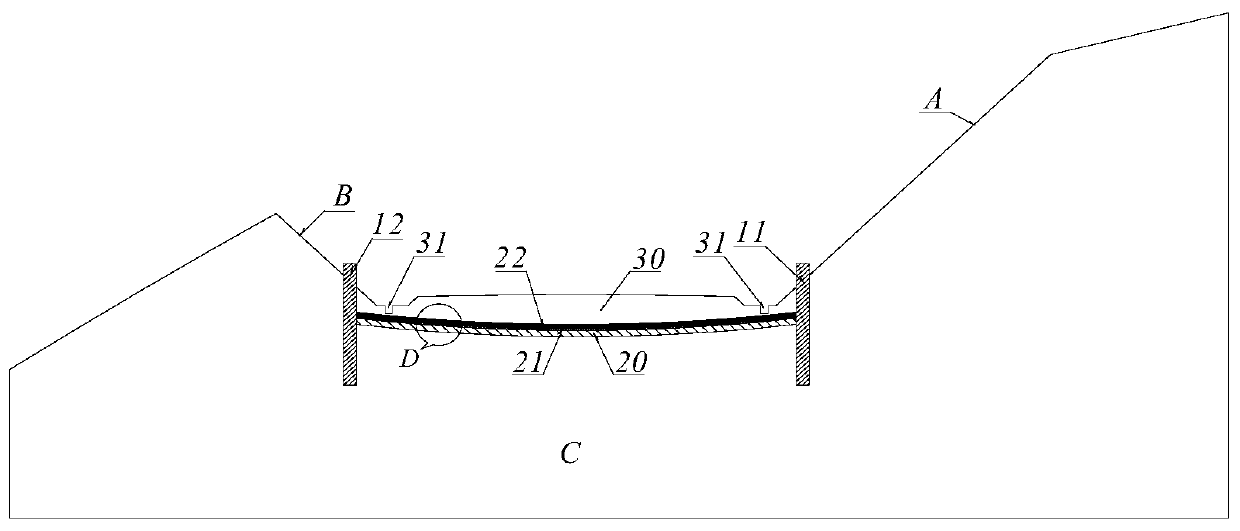

[0031] refer to figure 1 , figure 2 and image 3 , a high-speed railway soft rock deep cutting arch deformation control structure of the present invention includes a ballastless track subgrade 30 built on the soft rock bed C. On both sides of the ballastless track subgrade 30, the right side resistance pile 11 and the left side resistance pile 12 are arranged at intervals along the line direction on the right slope body A and the left side slope body B respectively, and the right side resistance pile 11 and the left side resistance pile The piles 12 go deep into a certain depth below the elevation of the foundation bed. On the top surface of the soft rock foundation bed C, a symmetrical and concave reinforced concrete arc-shaped plate 20 is arranged along the center line of the subgrade. Rigid connection as one....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com