Trailer bogie and rubber-tired train

A bogie and trailer technology, which is applied to steering mechanisms, steering tie rods, motor vehicles, etc., can solve the problems of non-limiting effect, large rotation angle of displacement deformation, affecting passenger comfort, etc., to prevent the rotation angle from being too large, The effect of preventing excessive deformation and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

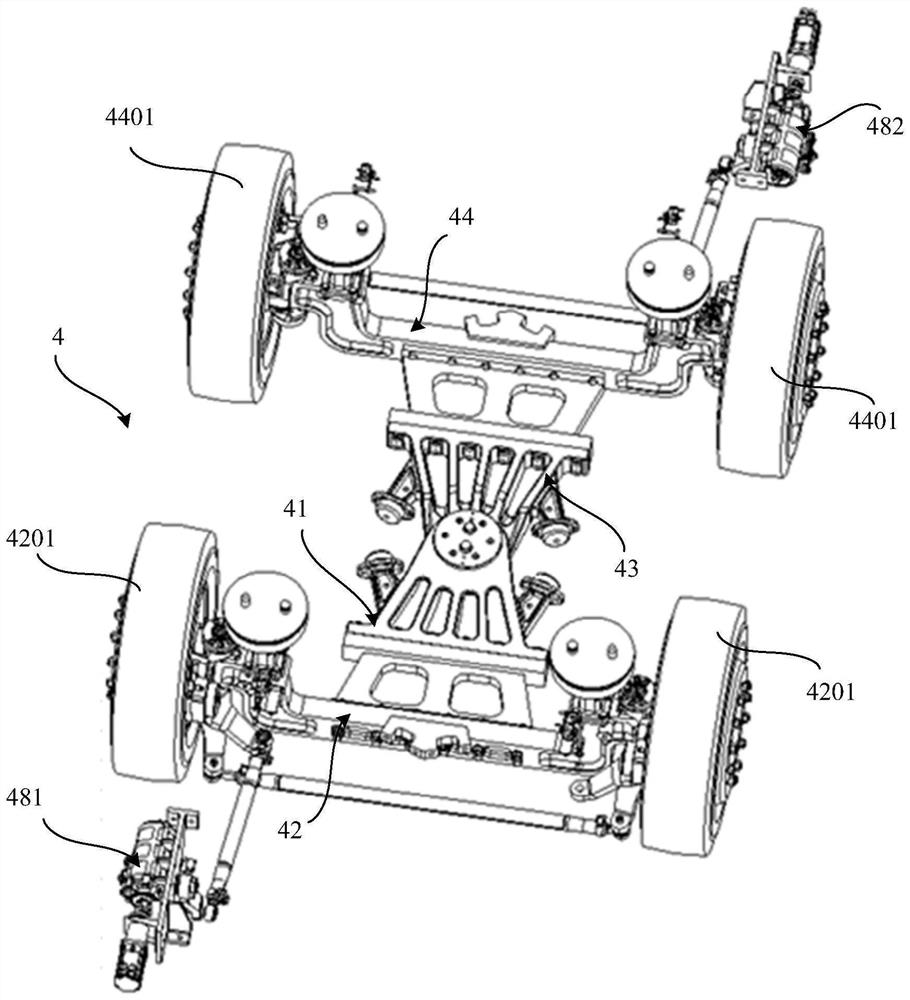

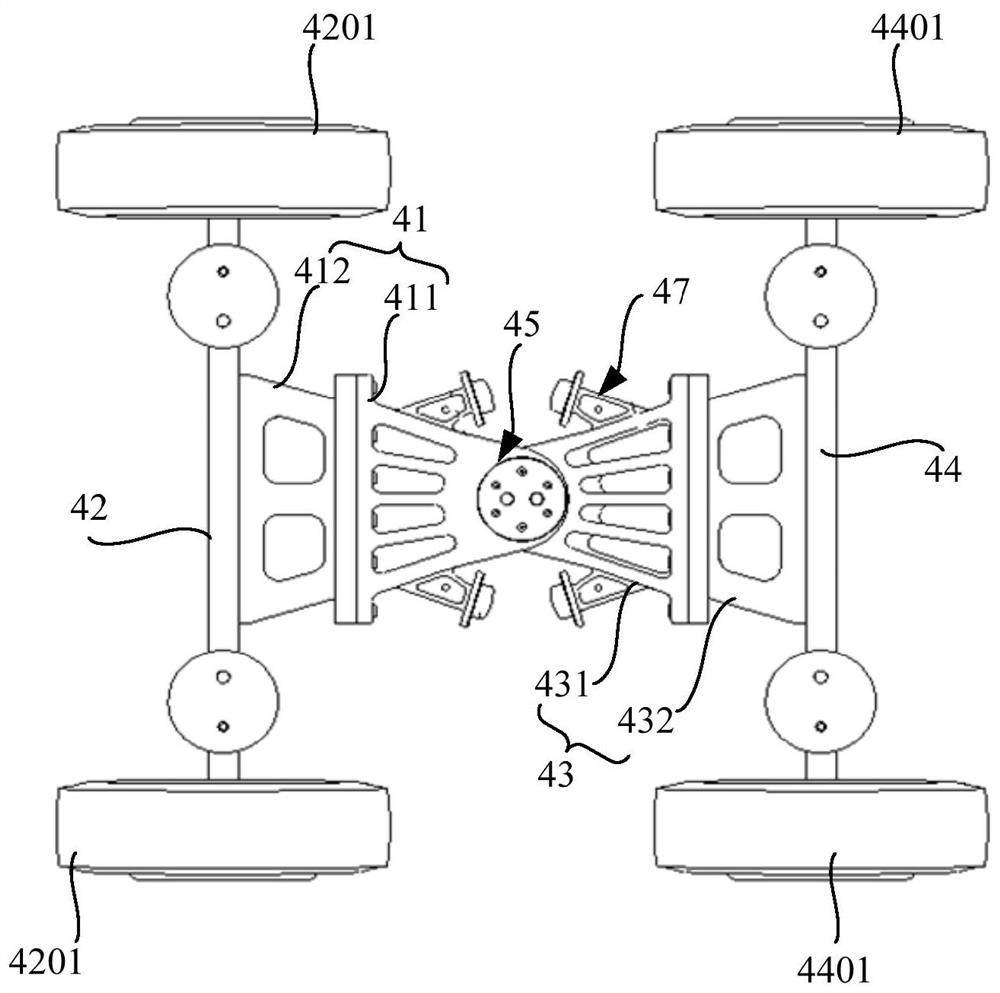

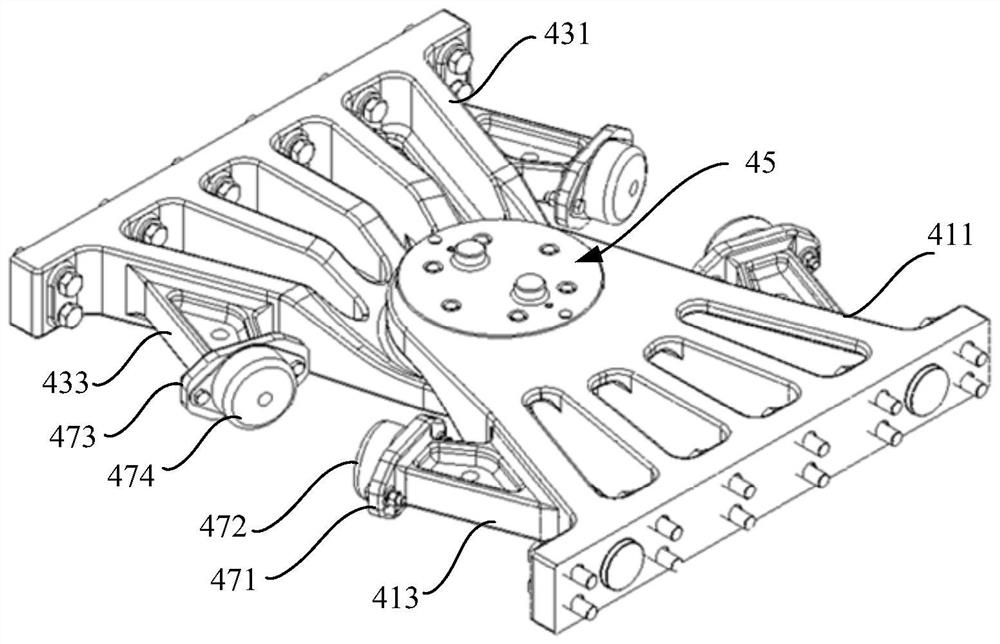

[0045] figure 1 Shown in is the structural diagram of the trailer bogie provided by an embodiment of the application; please refer to figure 1 . This embodiment provides a trailer bogie 4, which is installed under two adjacent first and second car bodies, not only for carrying the first and second car bodies, but also for Traction force is transmitted between the first vehicle body and the second vehicle body. Wherein, the first car body can be a motor car body, and the corresponding second car body can be an intermediate car body; or, the first car body can be an intermediate car body, and the corresponding second car body can be a motor car body; Alternatively, both the first vehicle body and the second vehicle body are intermediate vehicle bodies.

[0046] Specifically, the trailer bogie 4 includes a first frame body 41 and a second frame body 43; wherein, the first frame body 41 is used for connecting the first vehicle body, and the second frame body 43 is used for conn...

Embodiment 2

[0132] This embodiment provides a rubber-tired train, comprising: a first car body and a second car body opposite to the first car body, and the trailer as described in the first embodiment is passed between the first car body and the second car body Bogies are connected.

[0133] The rubber-tired train in the embodiment of the present application connects the adjacent first car body and the second car body through the trailer bogie involved in the first embodiment above, so that the first axle and the second axle can be close to the end of the car. The edge and the end part of the vehicle no longer need to be designed to adapt to the strong force structure such as traction force and braking force, which reduces the design difficulty of the end part of the vehicle; at the same time, it avoids the occupancy of the passenger space in the end area of the vehicle by the axle, and can realize a low floor.

[0134] The rubber-tired train of this embodiment connects the adjacent fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com