Condensate water and cooling water regenerating device of thermal power plant and nuclear power plant

A power generation device and cooling water technology, applied to steam engine devices, engine components, machines/engines, etc., can solve the problems of reducing power generation efficiency, wasting energy, and not being fully utilized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with embodiment this invention is further described:

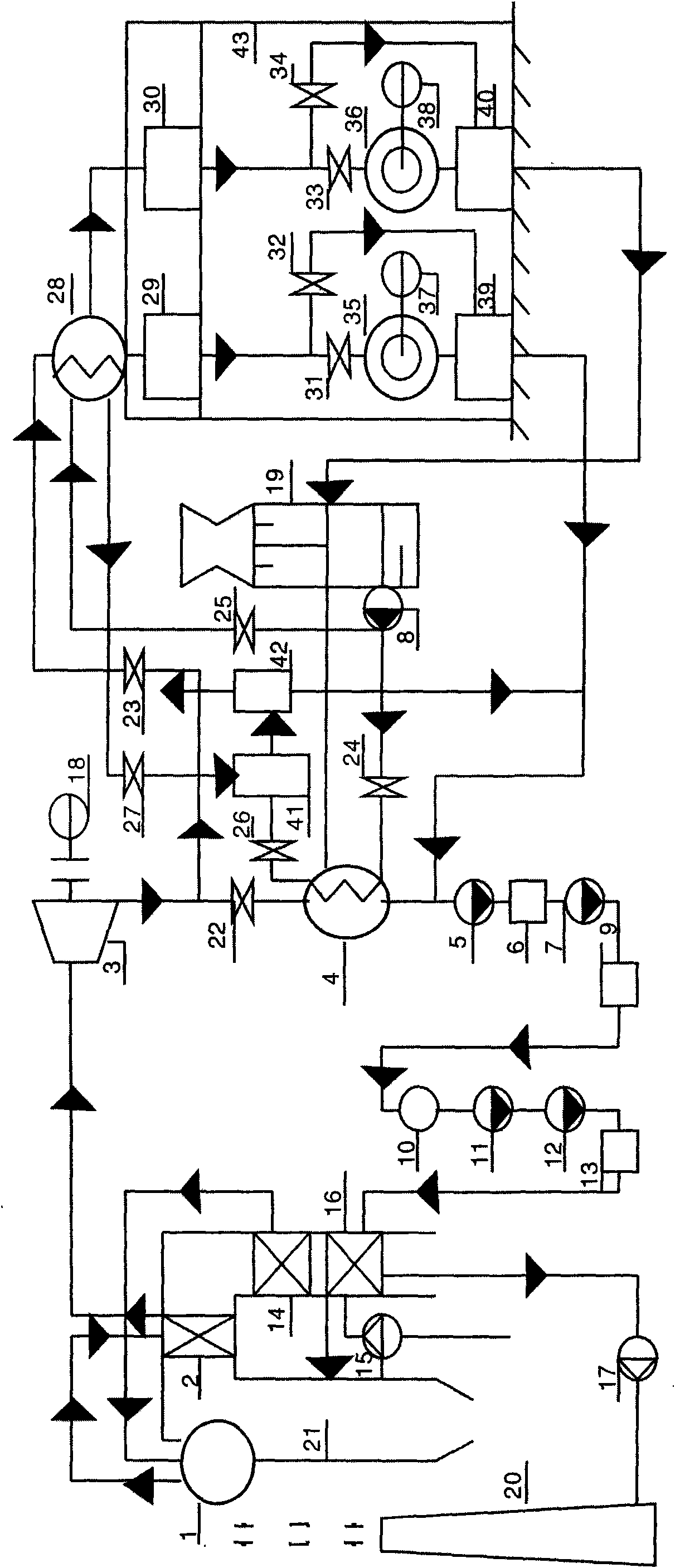

[0009] Such as figure 1 As shown, the original power generation system remains basically unchanged. Notes 1-21 in this figure except 8 and 19 are the flow chart notes of the power plant. Only a valve was added to the upper pipe of the original condenser, and a new bypass system was built. Close the upper valve 22 and open the bypass valve 23 so that the exhaust steam passes through the pipeline and is pressed into the condenser 28 on the mine rack platform 43 with a certain height in the bypass. Close the valve 24 on the cooling water system pipeline, open another valve 25 on the cooling water pipeline, and the cooling water is pressed into the bypass condenser under the pressure of the circulating water pump 8 for cooling. Close the valve 26 on the air extraction 41 and open the valve 27 on the air extraction pipeline to take out the vapor that is not condensed into water in the bypass conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com