Block metal glass containing iridium and preparation method thereof

A technology of bulk metal and glass, which is applied in the field of amorphous alloys, can solve the problems of increased processing difficulty, high melting point of iridium, and difficult processing of iridium, and achieve good mechanical properties and structural properties, high corrosion resistance and resistance, Strong ability to inhibit crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, preparation Ir 25 Ni 35 Ta 40 bulk metallic glass

[0036] The Ir, Ni and Ta components with a raw material purity of 99.9wt% (weight percent) are compounded in a molar ratio of 25:35:40; in an electric arc furnace with an argon atmosphere adsorbed by titanium, they are mixed through repeated smelting Homogeneous (that is, all the components are melted), and Ir is obtained after cooling 25 Ni 35 Ta 40 Master alloy ingot; then use the conventional metal mold casting method to remelt the ingot (as long as all the components are melted), and use the suction casting device in the electric arc furnace to suck the master alloy melt into the water-cooled copper mold, Get the composition as Ir 25 Ni35 Ta 40 , a large piece of metallic glass with a diameter of 2 mm.

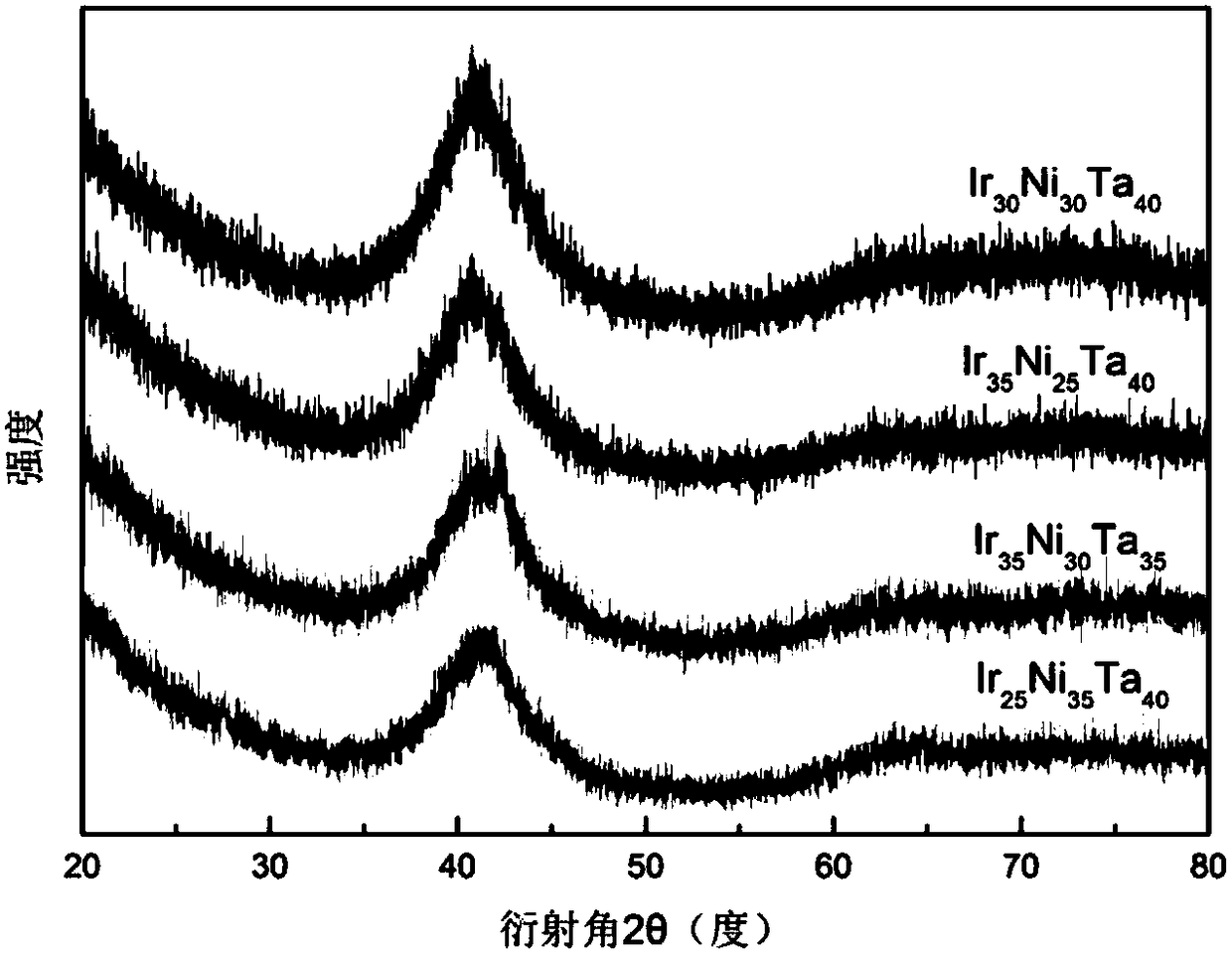

[0037] X-ray diffraction (XRD) of the metallic glass figure 1 As shown, it can be seen that Ir 25 Ni 35 Ta 40 The alloy is a completely amorphous alloy.

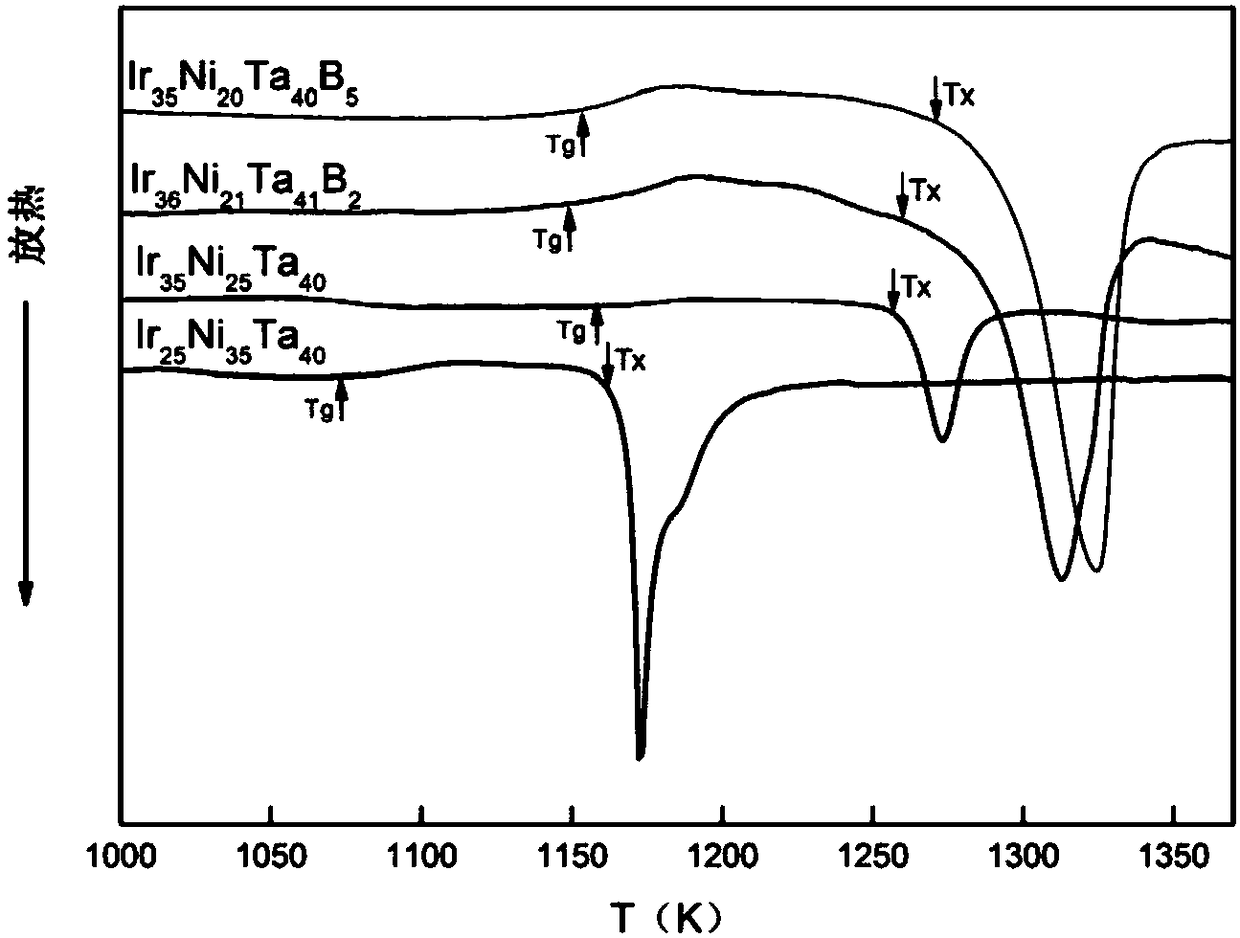

[0038] The differential scanning...

Embodiment 2-4、8、10-17、25 and 32-34

[0040] Examples 2-4, 8, 10-17, 25 and 32-34, preparation of other iridium-containing bulk metallic glasses

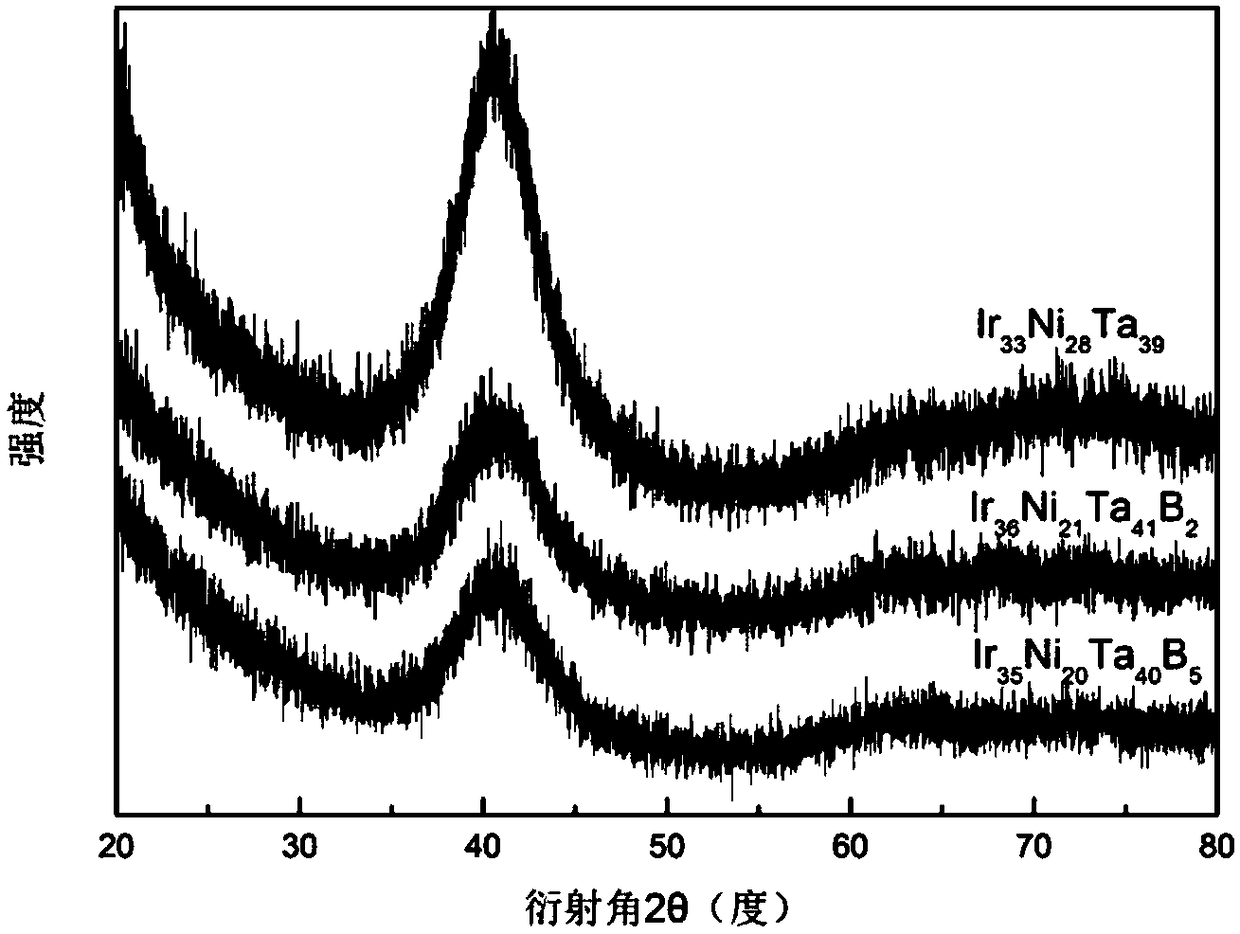

[0041] Iridium-containing bulk metallic glasses with various proportions and no B were prepared according to the method of Example 1, and their composition and thermophysical parameters are listed in Table 1.

[0042] The X-ray diffraction pattern of the iridium-containing bulk metallic glass sample prepared in embodiment 2-4 is as follows figure 1 As shown, it can be seen that these alloys are completely amorphous alloys.

Embodiment 3

[0043] The differential scanning calorimetry (DSC) curve figure of the iridium-containing bulk metallic glass sample prepared in embodiment 3 is as follows image 3 As shown, it can be seen from the figure that its glass transition temperature T g Compared with Example 1, it has increased by about 78K, T x It has been increased by 16K; the physical picture after static corrosion by aqua regia for 120 hours is as follows Figure 5 As shown (right in the picture), the surface still has a metallic luster, and the quality does not change within the error range (minimum precision 0.01mg).

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com