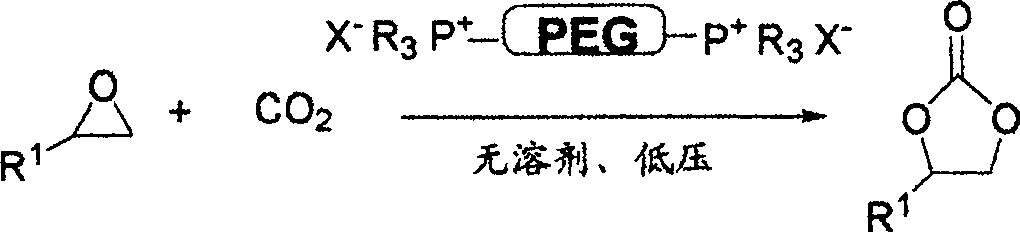

Method for preparing cyclic carbonate by using catalysis of periodic usable functional polyglycol

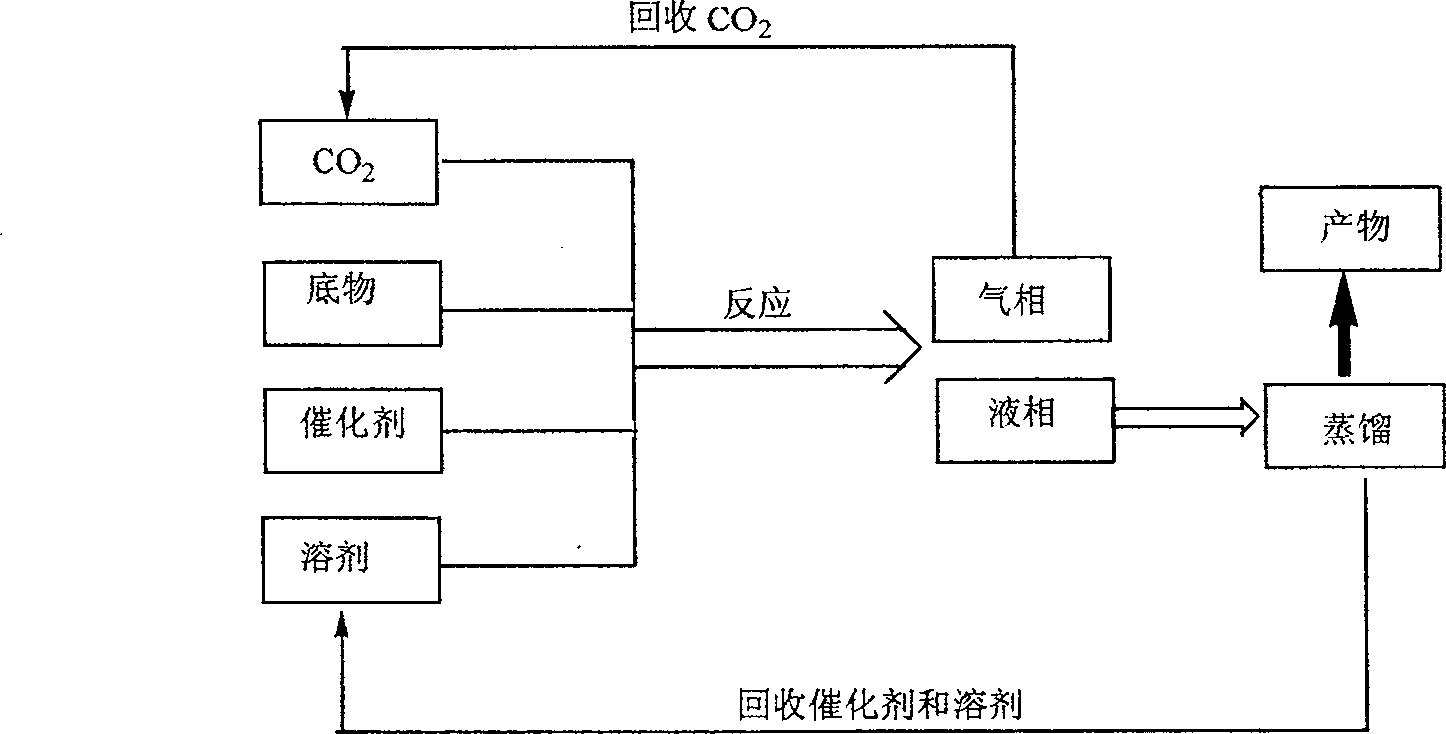

A cyclic carbonate and catalyst technology, applied in the field of preparing cyclic carbonate, can solve the problems such as the catalyst cannot be recovered and recycled, increase equipment investment, affect product quality, etc., achieve an environmentally friendly cleaning process, save processes, and improve product purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The synthesis of embodiment 1 cyclic carbonate

[0034] 1. Preparation of catalyst BrBu 3 PPEG 6000 PBu 3 Br

[0035] (1) Synthesis of Brominated Polyethylene Glycol

[0036]

[0037] In the 250ml three-necked bottle, add CH in sequence 2 Cl 2 (80ml), PEG 6000 (30g, 5mmol) (40°C, dried under vacuum), then cooled to 0°C with an ice-salt bath, and slowly added PBr 3 (6ml, 64mmol), after reacting for 5h, the reaction was continued for 10h at room temperature, and the reaction mixture was concentrated after the reaction was completed. Then add ether (newly steamed with sodium), let it slowly precipitate. The resulting solid was filtered with suction, washed twice with diethyl ether (freshly steamed with sodium), and dried to obtain 26.5 g of light yellow solid with a yield of 87%.

[0038] (2)BrBu 3 PPEG 6000 PBu 3 Synthesis of Br

[0039]

[0040] First evacuate the 250ml three-neck bottle, and inject N 2 , after repeating the operation twice, add 50ml ...

Embodiment 2

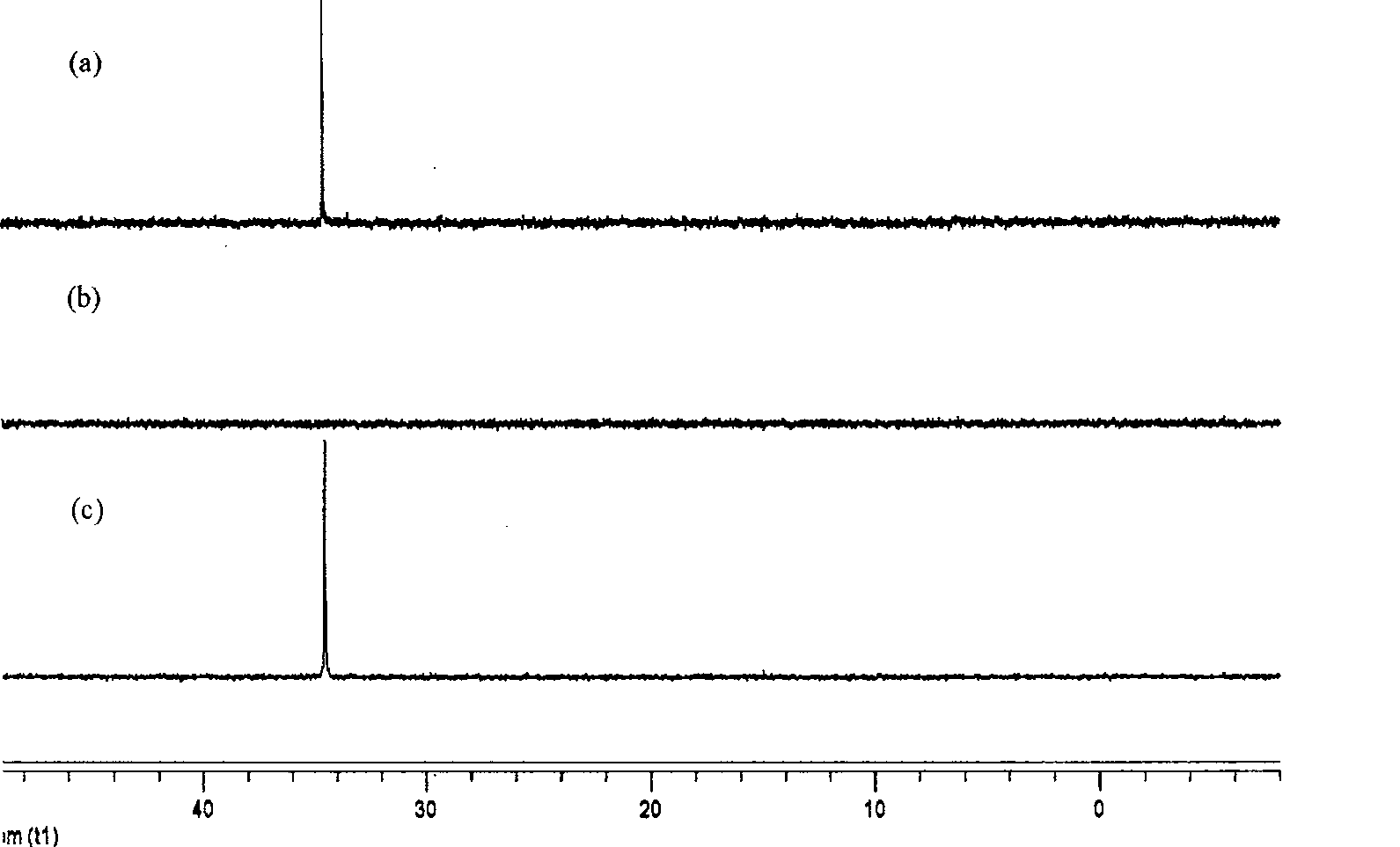

[0048] Embodiment 2 The inventive method and adopting phosphonium salt to do the comparison of catalyst synthesis result

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com