Downhole casing twin-stage cone expansion device and operating method thereof

A technology of expansion device and two-stage expansion, which is used in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of high expansion pressure, reduce construction risks, and reduce the expansion pressure of casing downhole, so as to reduce the expansion pressure. Pressure, reduce construction risk, reduce the effect of single-stage expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention will be further described now in conjunction with the accompanying drawings.

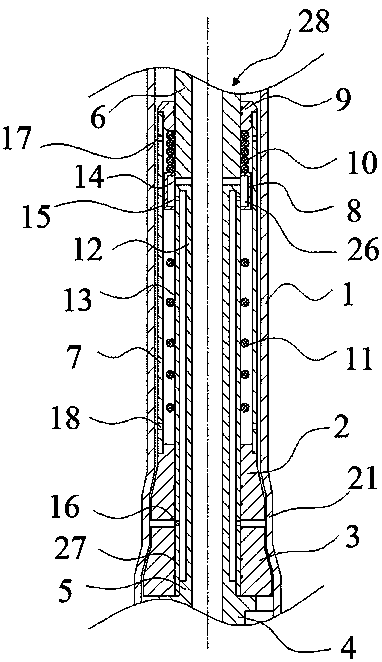

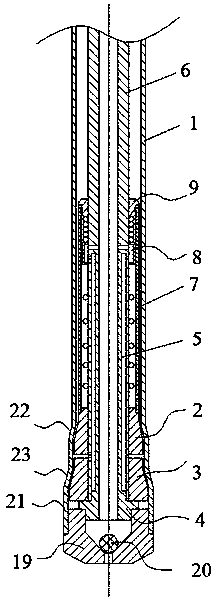

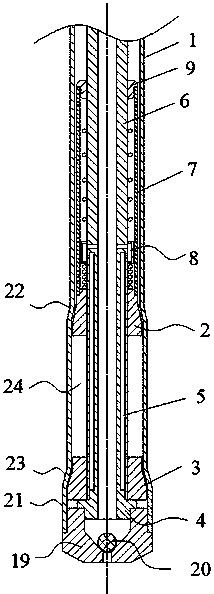

[0028] figure 1 It schematically shows the structure of an embodiment of the dual-stage cone expansion device for downhole casing according to the present invention. It includes an expansion sleeve 1, a primary expansion cone 2, a secondary expansion cone 3, a central tube 28, a connecting outer tube 7, a limit mechanism 8 and a top stopper 9 and other components.

[0029] The central tube 28 includes parts such as a spline shaft 4, a double-layer inner tube 5, and a connecting inner tube 6. The spline shaft 4, the double-layer inner tube 5 and the connecting inner tube 6 are sequentially connected to form, and the connecting inner tube 6 and the double-layer inner tube A position-limiting mechanism 8 is installed at the joint of the pipe 5 . The first-stage expansion cone 2 and the second-stage expansion cone 3 are installed on the spline shaft 4 and the double-layer inner pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com