Inflatable safety valve for emulsion pump

An emulsion pump and safety valve technology, which is used in mining equipment, earth-moving drilling, pillars/supports, etc., can solve the problems of large shape, large volume and exaggeration of the safety valve, and achieve the effect of long life and good anti-fouling ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

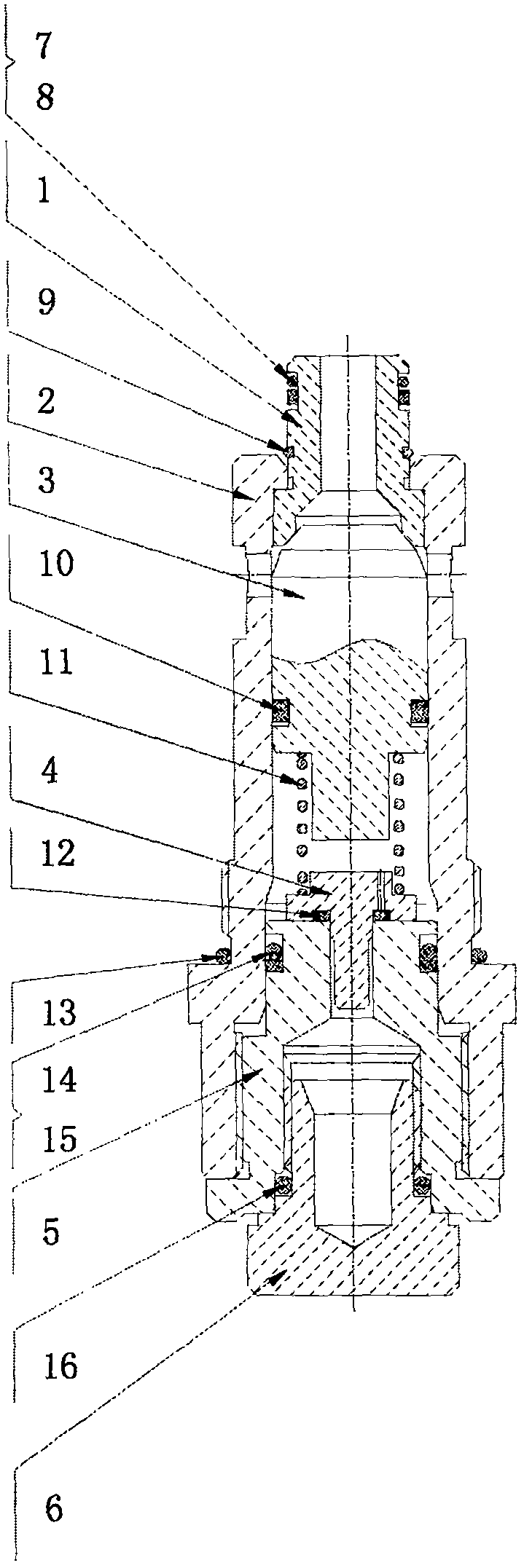

[0009] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0010] see figure 1 , one An inflatable safety valve for an emulsion pump includes a joint 1, a casing 2, a valve core 3, an air valve 4, a screw sleeve 5, a screw plug 6, a small spring 11 and corresponding sealing rings. The joint 1 is axially opened with a main liquid inlet hole and a sealing port. The conical surface of the valve core 3 and the sealing port of the joint 1 form a hard seal pair, which improves the service life and anti-fouling ability of the liquid chamber. The outer groove sealing ring 10 on the valve core 3 can ensure the reliability of nitrogen radial sealing. The small sealing ring 12 forms an axial seal with the screw sleeve 5 on the end face groove of the air valve 4 to ensure timely one-way sealing and locking after inflation. The casing 2 is provided with four evenly distributed liquid discharge holes in the radial direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com