Anti-freezing cracking concrete and preparation method thereof

A technology of concrete and mixture, applied in the field of concrete, can solve the problems affecting the safety of concrete buildings, low anti-expansion strength of concrete, poor frost resistance of concrete, etc. pumping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

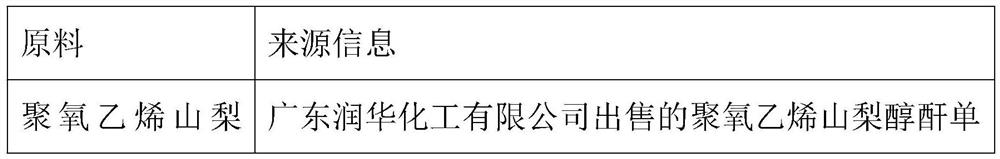

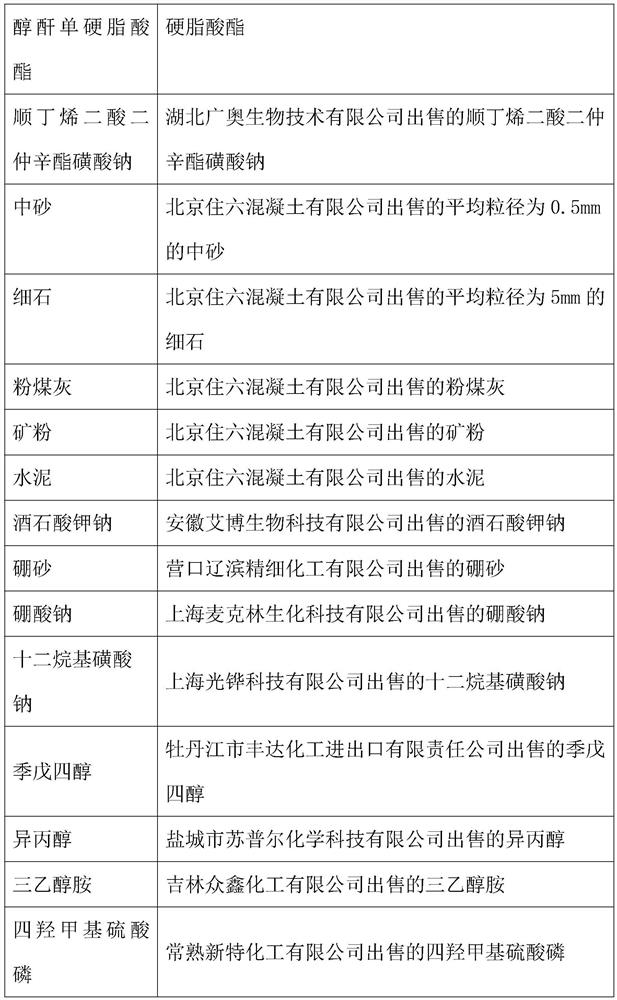

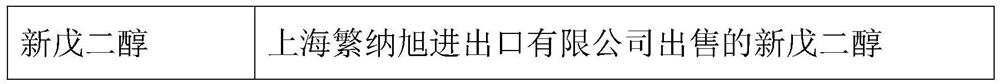

[0063] Embodiment 1-3: a kind of antifreeze cracking concrete, comprises following component:

[0064] Polyoxyethylene sorbitan monostearate, sodium dioctyl sulphonate maleate, coarse aggregate, fine aggregate, cement, water.

[0065] Coarse aggregate is a compound of medium sand and fine stone.

[0066] The fine aggregate is a compound of fly ash and mineral powder.

[0067] In Examples 1-3, see Table 2 for the input amount (unit Kg) of each component.

[0068] Table 2

[0069] Example 1 Example 2 Example 3 Polyoxyethylene sorbitan monostearate 2 6 10 Sodium di-sec-octyl maleate sulfonate 2 3 4 Middle sand 850 900 950 fine stone 750 800 850 fly ash 5 67 130 mineral powder 25 85 145 cement 300 325 350

[0070] The preparation method of the antifreeze cracking concrete of embodiment 1-3 comprises the following steps:

[0071] Step 1), take polyoxyethylene sorbitan monostearate and di-sec-octyl sodium...

Embodiment 4

[0075] A kind of frost-resistant cracking concrete, compared with embodiment 2, the difference only lies in:

[0076] In step 1), polyoxyethylene sorbitan monostearate and sodium di-sec-octyl maleate sulfonate are added to the first mixer together with water, and heated to 75°C.

[0077] The molecular weight of polyoxyethylene sorbitan monostearate is 1300.

Embodiment 5

[0079] A kind of concrete using recycled concrete aggregate, compared with embodiment 2, the only difference is:

[0080] In step 1), polyoxyethylene sorbitan monostearate and di-sec-octyl sodium maleate sulfonate are added to the first mixer together with water, and heated to 80°C.

[0081] The molecular weight of polyoxyethylene sorbitan monostearate is 1400.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com