Control method of tamping coking resistance

A control method and resistance technology, which is applied in the field of coking, can solve the problems of high resistance in tamping coking, damage to the furnace body, shortening the service life of coke ovens, etc., and achieve the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0041] (1) According to the "China National Standard for Coal Classification GB5751-86", the tamping coking coal is divided into gas coal, fat coal, coking coal, 1 / 3 coking coal and lean coal.

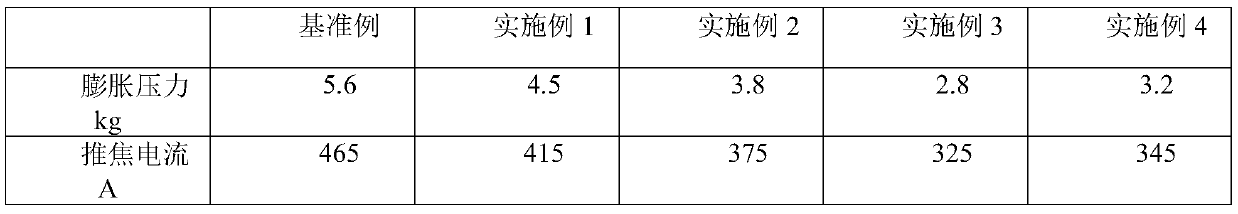

[0042] (2) Utilize the tamping briquette expansion pressure tester to measure the maximum expansion pressure of various tamping coking single coals, and the measurement results are shown in Table 1;

[0043] (3) According to the measurement results of the maximum expansion pressure of single coal for tamping and coking coal, the coal blending structure is adjusted. After adjustment, the total weight of coal blending is 100%.

[0044] Table 1

[0045] coal type Maximum expansion pressure kg coal type Maximum expansion pressure kg coking coal 1 4.9 1 / 3 coking coal 1 1.9 coking coal 2 3.5 1 / 3 coking coal 2 0.8 coking coal 3 2.2 1 / 3 coking coal 3 3.2 coking coal 4 2.6 1 / 3 coking coal 4 1.3 coking coal 5 3.4 1 / 3 coking coal 5 2.6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com