Bionic shale inhibitor and preparation method thereof and drilling fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

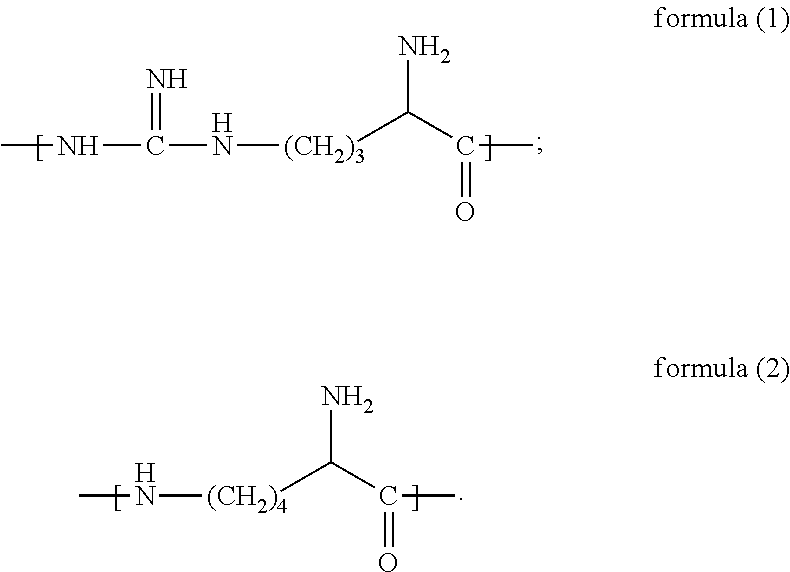

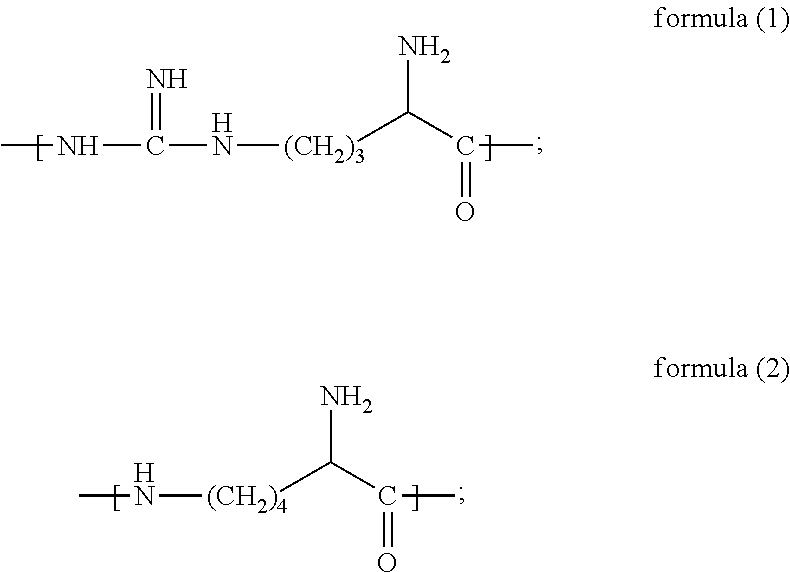

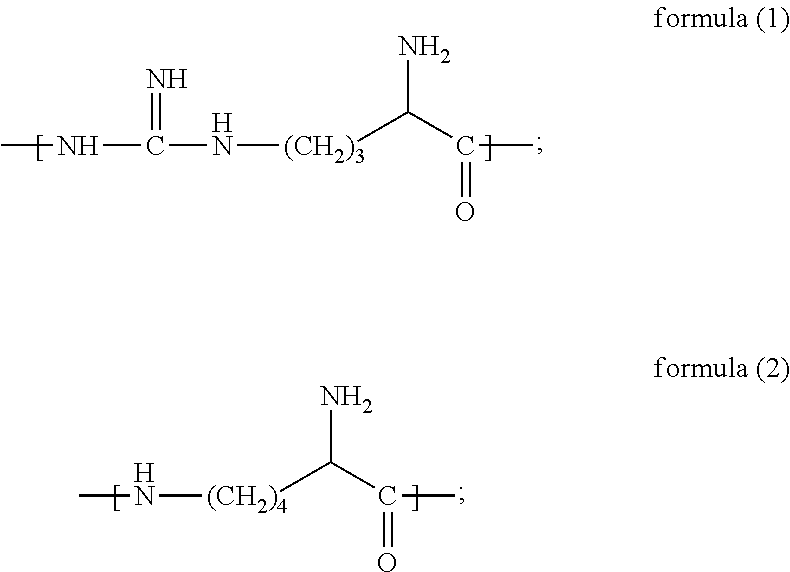

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0046]This example is provided to describe the bionic shale inhibitor and the method for preparation of the bionic shale inhibitor in the present subject matter.

[0047]Stir and mix 0.5 mol (87.1 g) L-arginine and 0.2 mol (29.2 g) L-lysine at 195° C., add 1.75 mol (171.5 g) phosphoric acid (85 wt. % phosphoric acid aqueous solution), and hold for 16 h at 195° C. for reaction. Add 200 g water when the temperature drops to about 120° C. after the reaction is completed, and continue stirring for 20 min., so that the product is completely dissolved in water. Then, take out the reaction product (water solution) and dry it at about 120° C. to obtain a solid product, dissolve the solid product in dimethyl sulfoxide, and separate the insoluble substances from the solution by suction filtration. Next, evaporate the solution by rotary evaporation; thus, 91.8 g bionic shale inhibitor disclosed in the present subject matter is obtained. Measured by gel permeation chromatography, the weight-averag...

example 2

[0048]This example is provided to describe the bionic shale inhibitor and the method for preparation of the bionic shale inhibitor in the present subject matter.

[0049]Stir and mix 0.8 mol (139.4 g) L-arginine and 0.2 mol (29.2 g) L-lysine at 200° C., add 0.35 mol (34.3 g) phosphoric acid (85 wt. % phosphoric acid aqueous solution), and hold for 8.5 h at 200° C. for reaction. Add 200 g water when the temperature drops to about 120° C. after the reaction is completed, and continue stirring for 20 min., so that the product is completely dissolved in water. Then, take out the reaction product (water solution) and dry it at about 120° C. to obtain a solid product, dissolve the solid product in dimethyl sulfoxide, and separate the insoluble substances from the solution by suction filtration. Next, evaporate the solution by rotary evaporation; thus, 145.8.8 g bionic shale inhibitor disclosed in the present subject matter is obtained. Measured by gel permeation chromatography, the weight-av...

example 3

[0050]This example is provided to describe the bionic shale inhibitor and the method for preparation of the bionic shale inhibitor in the present subject matter.

[0051]Stir and mix 0.8 mol (139.4 g) L-arginine and 0.3 mol (43.9 g) L-lysine at 215° C., add 0.45 mol (44.1 g) phosphoric acid (85 wt. % phosphoric acid aqueous solution), and hold for 9 h at 215° C. for reaction. Add 200 g water, and continue stirring for 20 min., so that the product is completely dissolved in water. Then, take out the reaction product (water solution) and dry it at about 120° C. to obtain a solid product, dissolve the solid product in dimethyl sulfoxide, and separate the insoluble substances from the solution by suction filtration. Next, evaporate the solution by rotary evaporation; thus, 158.4.8 g bionic shale inhibitor disclosed in the present subject matter is obtained. Measured by gel permeation chromatography, the weight-average molecular weight Mw is 2,480 g / mol, and the molecular weight distributio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Molar mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com