Compact cycloidal wheel magnetorheological coupling

A technology of coupling and cycloid wheel, which is applied in the field of compact cycloid wheel magneto-rheological coupling, can solve the problems of inconvenient installation and maintenance, small transmission torque, inability to apply high power and heavy load, etc., and achieve The effect of increasing the effective contact area, improving the working life, and reducing the axial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with accompanying drawing

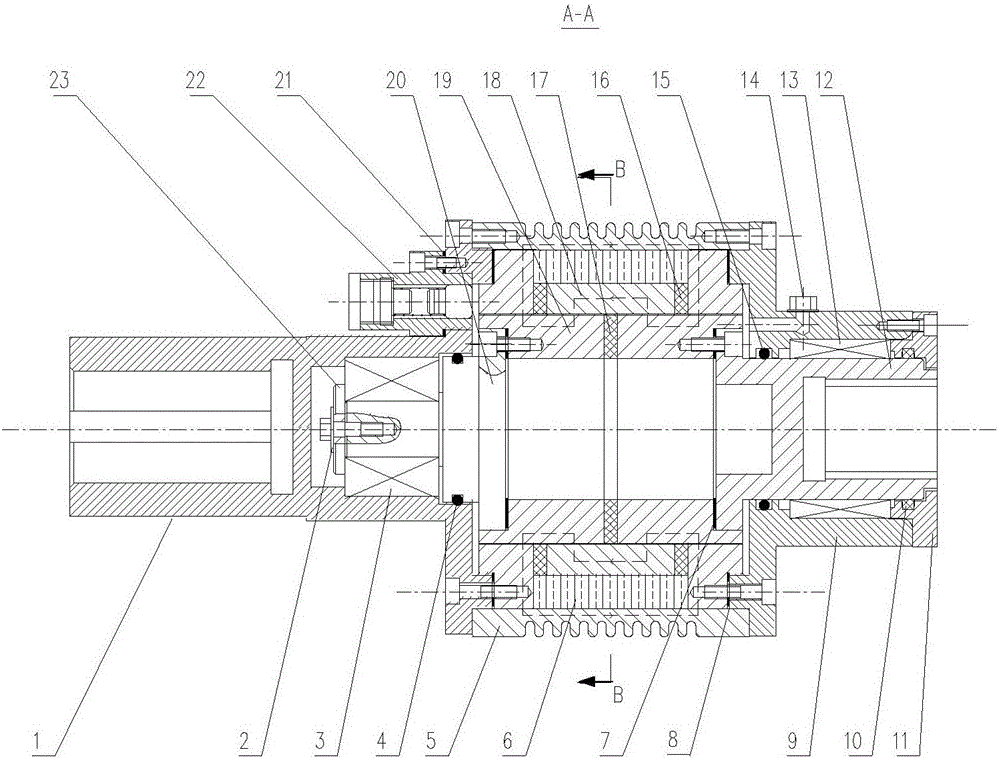

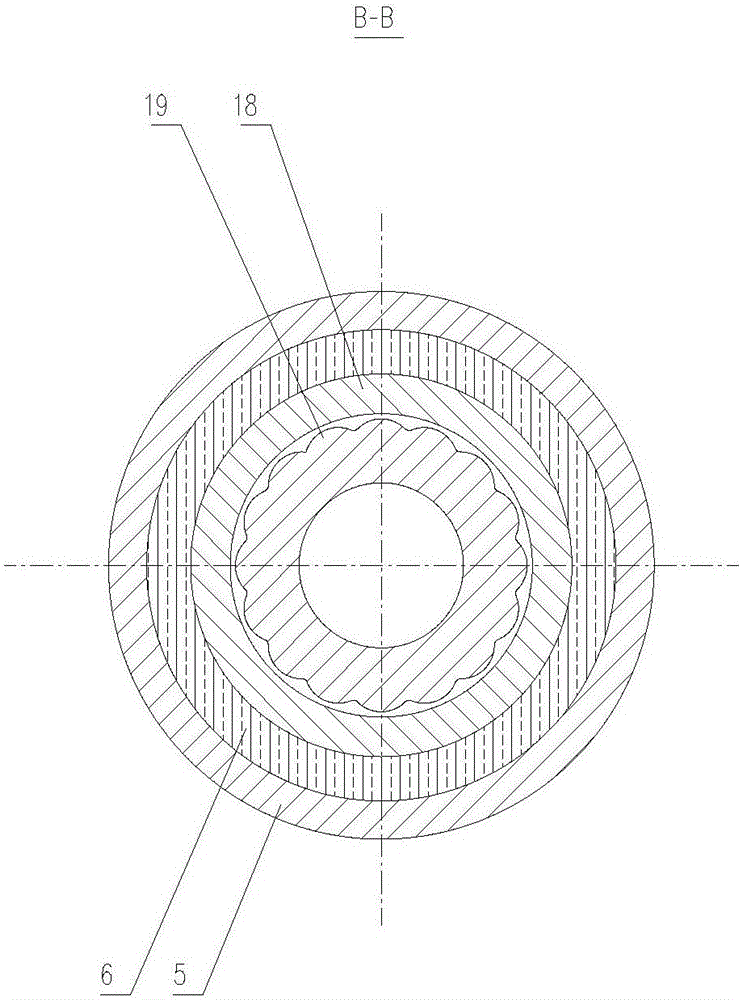

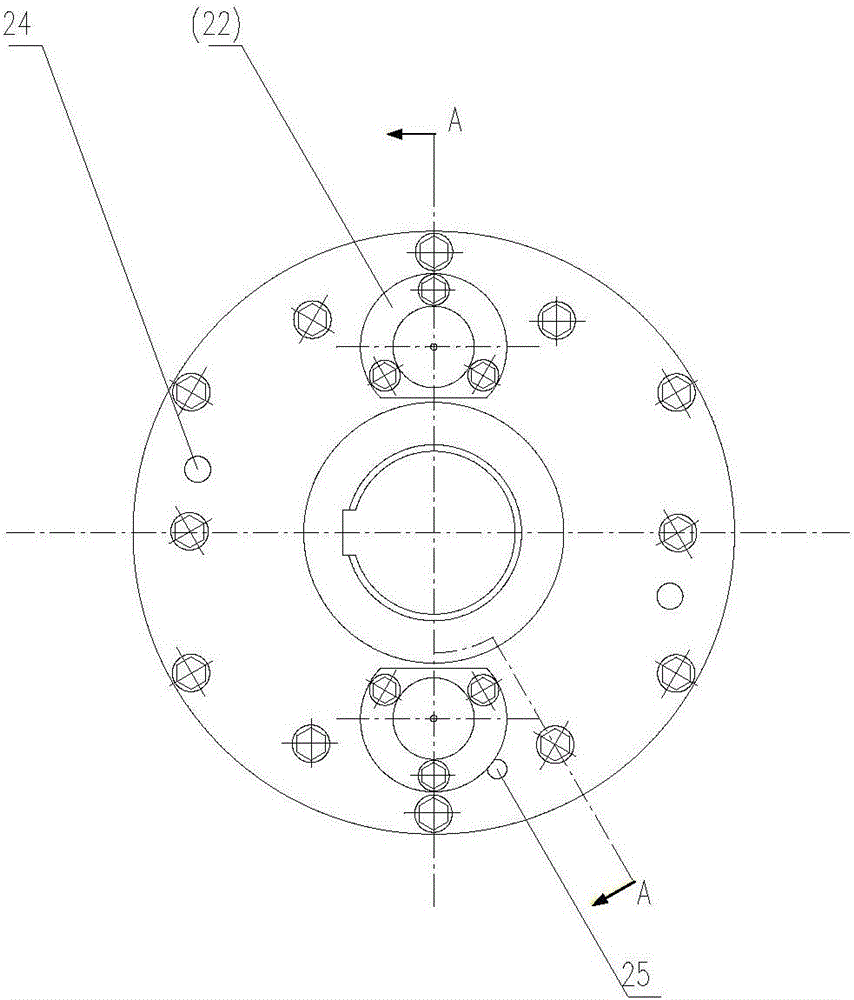

[0022] Such as figure 1 Shown, the present invention is made up of outer rotating part and inner rotating part. External rotating parts include input coupling 1, anti-loosening washer 2, outer sleeve 18, heat sink 5, sealing gasket 8, 21, transparent cover 9, dust seal 10, sealing cover 11, large magnetic isolation ring 16, pressure relief Valve 22, electromagnetic coil 6. The outer sleeve 18 is composed of three annular magnetizers welded with magnetic isolation rings distributed symmetrically along the axial direction on both sides and formed by machining. The annular groove is wound with a multi-turn electromagnetic coil 6 that can generate a magnetic field. The input end The two ends of coupling 1, transparent cover 9 and outer sleeve 18 are respectively connected by magnetically isolated stainless steel screws, cylindrical pins are inserted into the input en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com