Intensified reinforced concrete sewer pipe steel mold

A technology for reinforced concrete and drainage pipes, applied in molds and other directions, can solve problems affecting production quality, uneven RCC, high concrete slump requirements, etc., achieve simple structure, high safety, and ensure production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

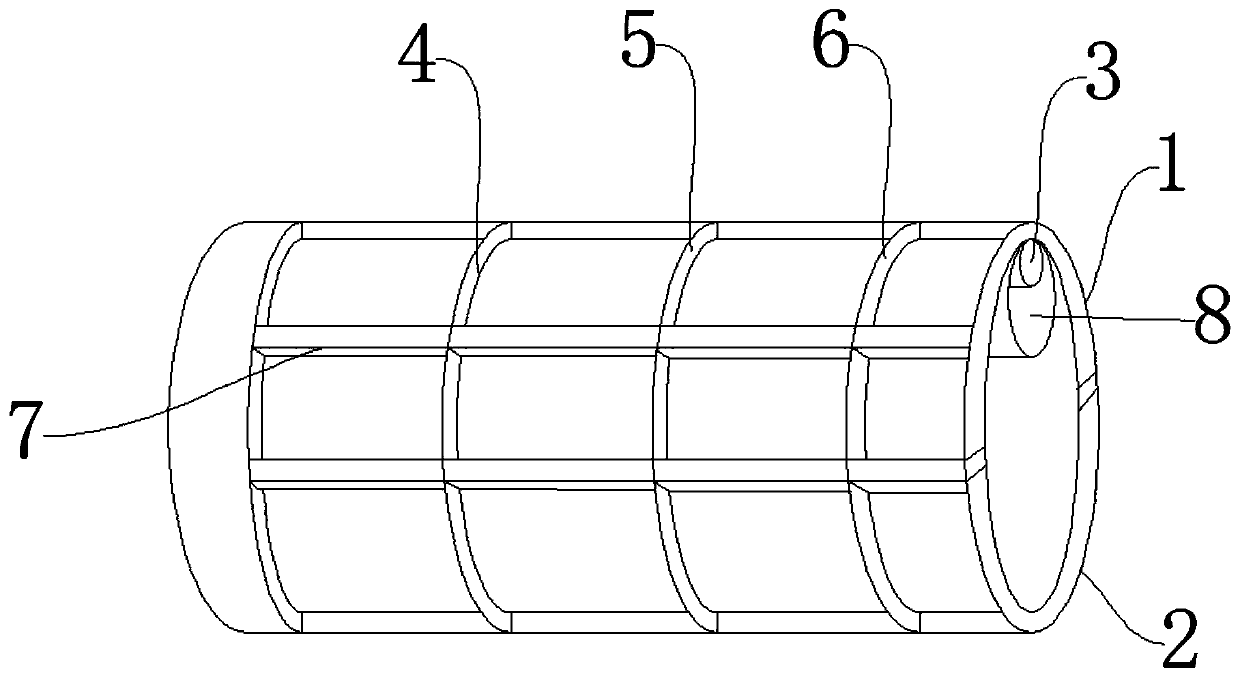

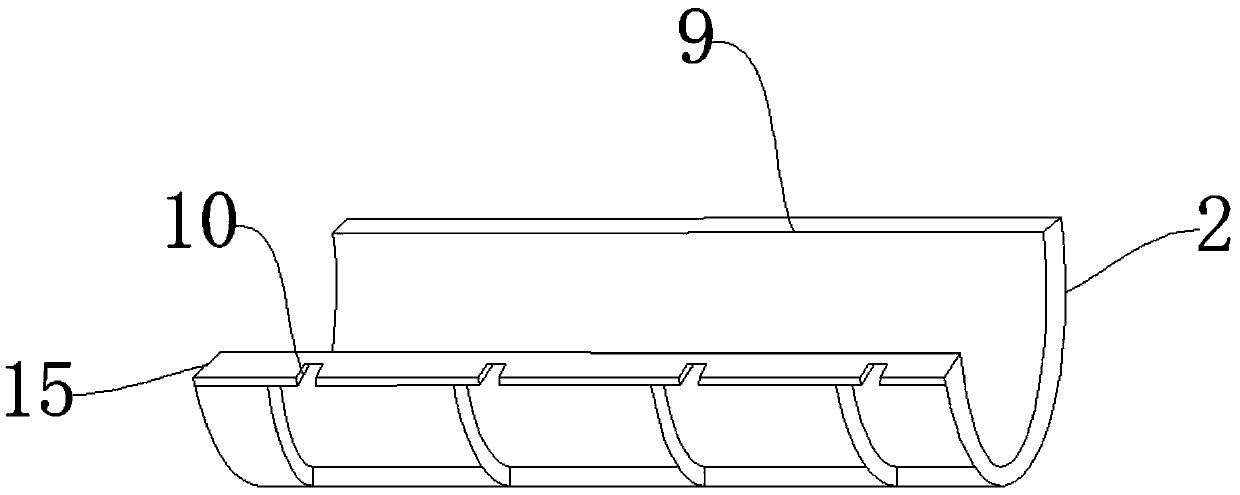

[0034] Such as Figure 1-Figure 5 As shown, a reinforced concrete drainage pipe steel mold includes an upper cylinder body 1, a lower cylinder body 2, an installation hole 3, a first support flange 4, a second support flange 5, a third support flange 6, an upper The lower end of the cylinder 1 is provided with a lower cylinder 2, and the inside of the upper cylinder 1 is provided with a steel cylinder 8. The steel cylinder 8 is used to increase the pressure area, and the inside of the steel cylinder 8 is provided with a mounting hole 3. Roller machine 17, a first support flange 4 is arranged on the outside of the upper cylinder body 1, and the first support flange 4 is used to increase the strength, and a second support flange 5 is arranged on one side of the first support flange 4, and the second support method One side of the flange 5 is provided with a third support flange 6, and the front side of the upper cylinder 1 is provided with a reinforcing cross bar 7, which is use...

Embodiment 2

[0036] The difference between this embodiment and embodiment 1 is:

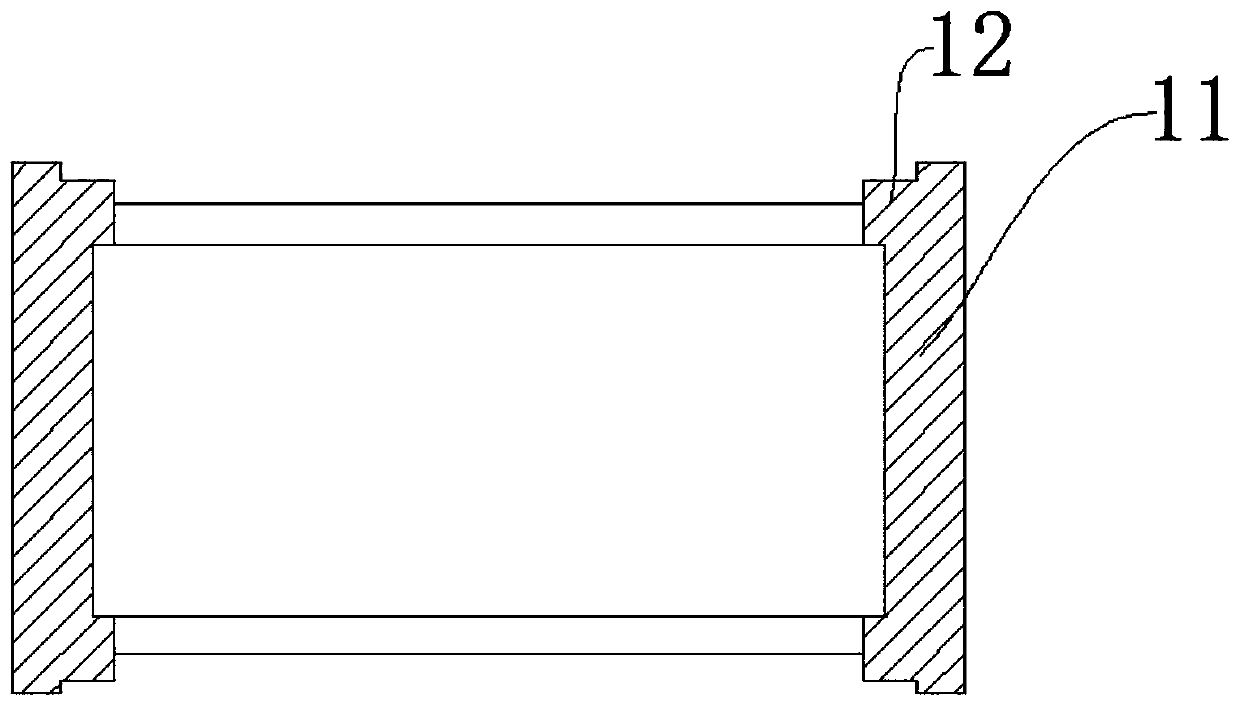

[0037] Fixing bolt 13 is arranged between upper connecting plate 14 and lower connecting plate 15, and upper connecting plate 14 is connected with lower connecting plate 15 by fixing bolt 13, and fixing bolt 13 is connected and helps upper connecting plate 14 and lower connecting plate 15 to be connected more. firm.

[0038] Working principle: Before work, assemble the drainpipe steel mold 16 and install it on the suspension roller machine 17. Before the suspension roller is formed, put the steel cylinder 8 on the suspension roller shaft 18 to replace the suspension roller shaft 18 to roll the reinforced concrete Drainpipe steel mold 16 inner wall 9, directly drainpipe steel mold 16 is disassembled after pipe body forming, takes out reinforced concrete drainpipe, then steel cylinder 8 is extracted from hanging roller machine 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com