Suspension Roll Formed Reinforced Concrete Drainage Pipe Maintenance Structure and Its Maintenance Method

A technology of reinforced concrete and drainage pipes, which is applied in the field of building construction, can solve the problems of high concrete slump and difficulty in controlling the static stop time, and achieves easy control of the static stop time, suitable for large-scale promotion and use, and roller compacted concrete Even and dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

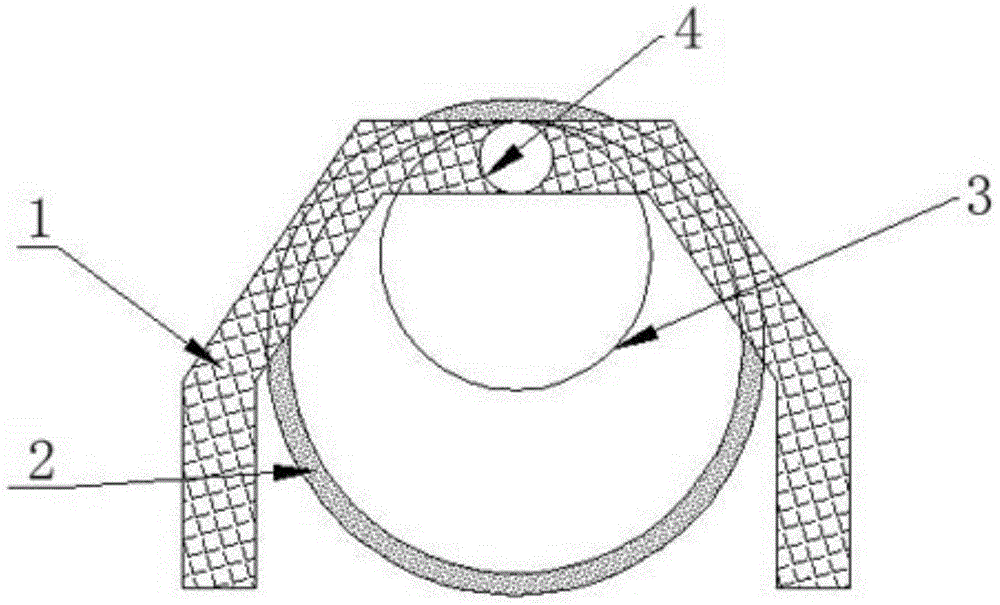

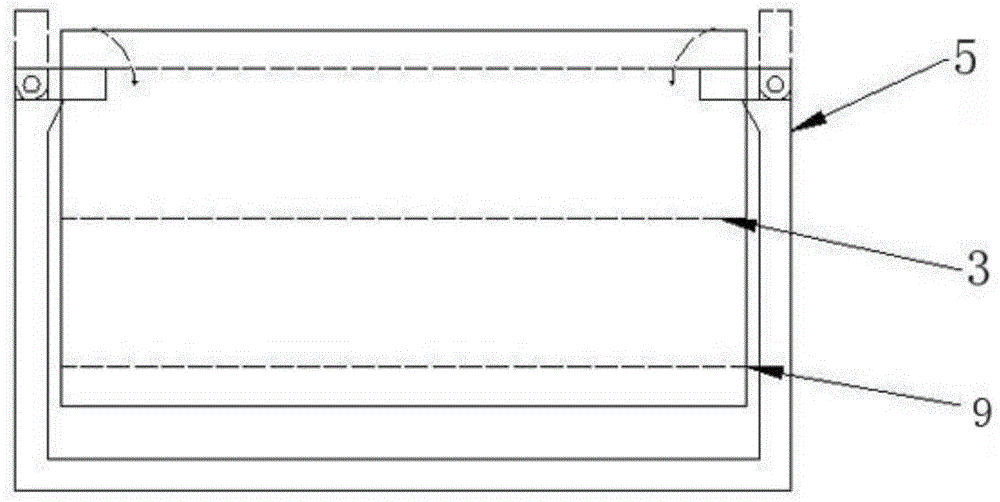

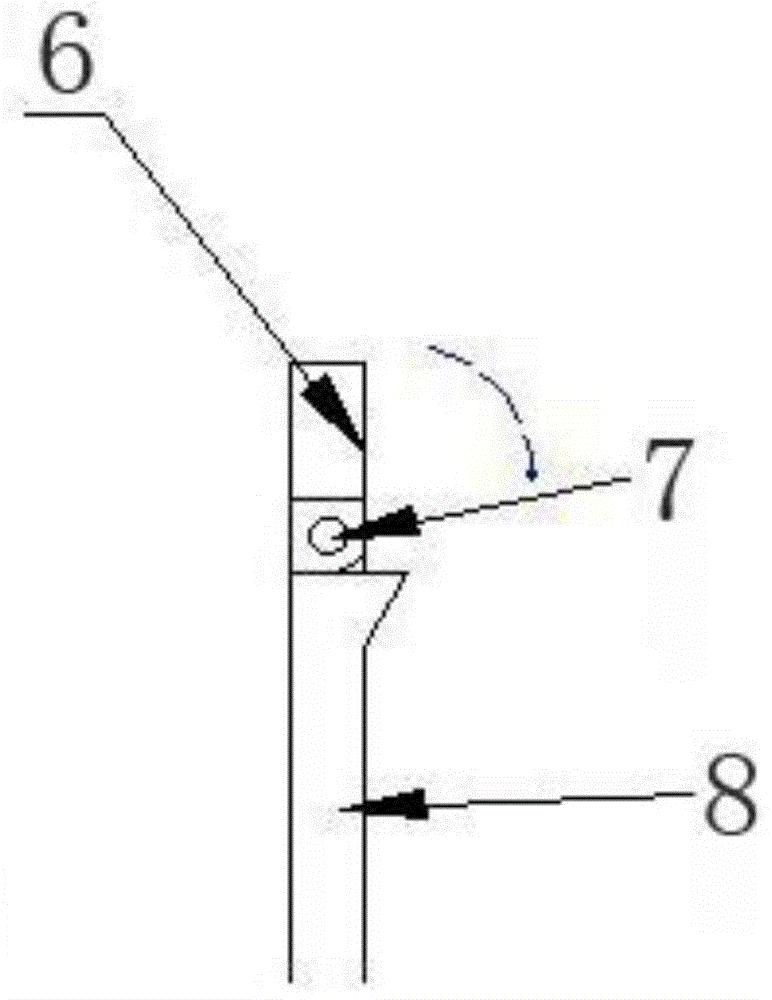

[0025] Such as Figure 1-4 As shown, the suspension roller forming reinforced concrete drainage pipe maintenance structure includes a reinforced concrete drainage pipe steel mold 2, a steel cylinder 3 located inside the reinforced concrete drainage pipe steel mold 2 and extending from both ends of the reinforced concrete drainage pipe steel mold 2, The steel cylinder is used to be sleeved on the suspension roller shaft 4 of the suspension roller machine 1, and also includes a movable support 5 for static stopping after the suspension roller is formed, and a group of movable supports 5 are set according to a drain pipe in the maintenance area. In this embodiment, the movable support 5 is a support with a symmetrical upper arm that can rotate by 90°, including a support 8, a rotating shaft 7 arranged on the top of the supporting frame 8, and a movable arm 6 that rotates on the rotating shaft and is used to support the steel cylinder.

[0026] The steel cylinder is a cylindrical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com