Novel pouring structure for mould

A new type of mold and gate technology, applied in the field of mold processing, can solve the problems of easy deformation of the gate, and achieve the effect of improving the yield rate and reducing the instantaneous momentum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific implementation methods.

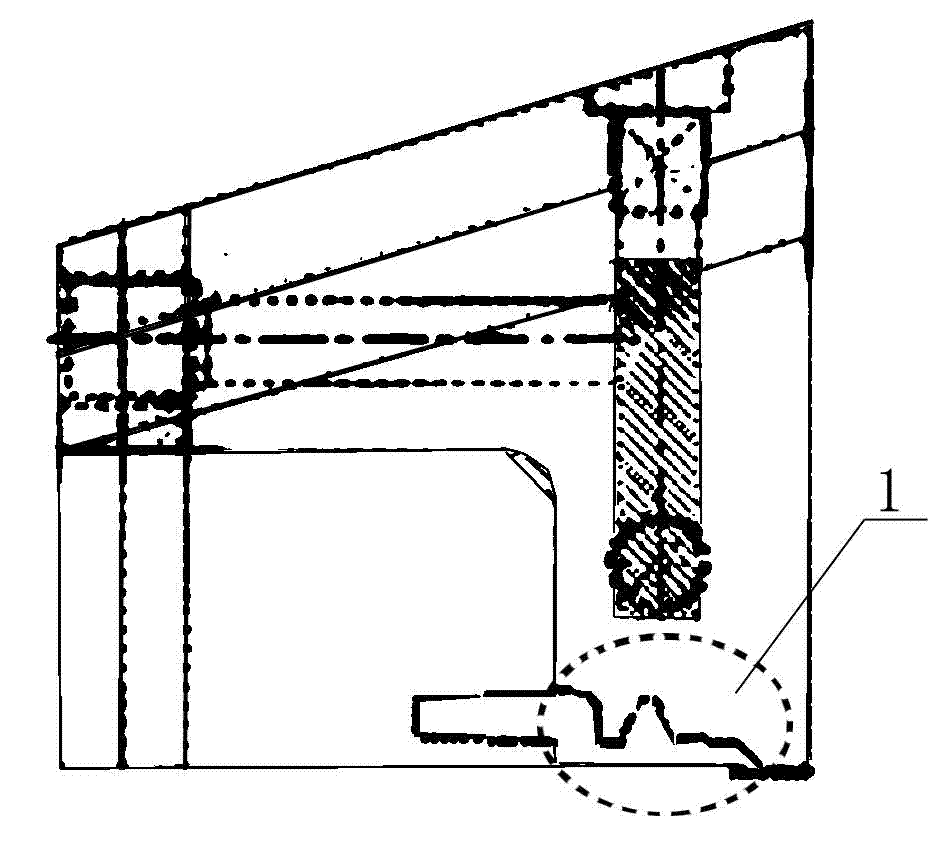

[0012] As shown in the figure, a new type of mold pouring structure includes a main channel, a branch channel and a gate channel 1 connecting the branch channel and the cavity. The gate channel 1 has an irregular cavity, The wall surface of the cavity is provided with depressions or protrusions, and the depressions and protrusions are curved or formed by a combination of slopes and planes.

[0013] like figure 1 As mentioned above, a buffer transition cavity is provided in the middle of the gate runner 1, and the buffer transition cavity is concave upward. When the colloid enters, a part of the colloid continues to flow forward, while the other part can temporarily store in the buffer transition cavity. In the transition cavity, reduce the impu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com