Method for connecting aluminum electrolysis multifunctional overhead crane orbit telescopic seam

A connection method and technology of expansion joints, applied in the direction of rail system, load hanging components, transportation and packaging, etc., can solve the problems of crane gnawing on rails, loose or falling platens, easy crushing and deformation, etc., and achieve good vertical and horizontal The effect of telescopic spacing, eliminating the gnawing of the crane rail, and increasing the pressure area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

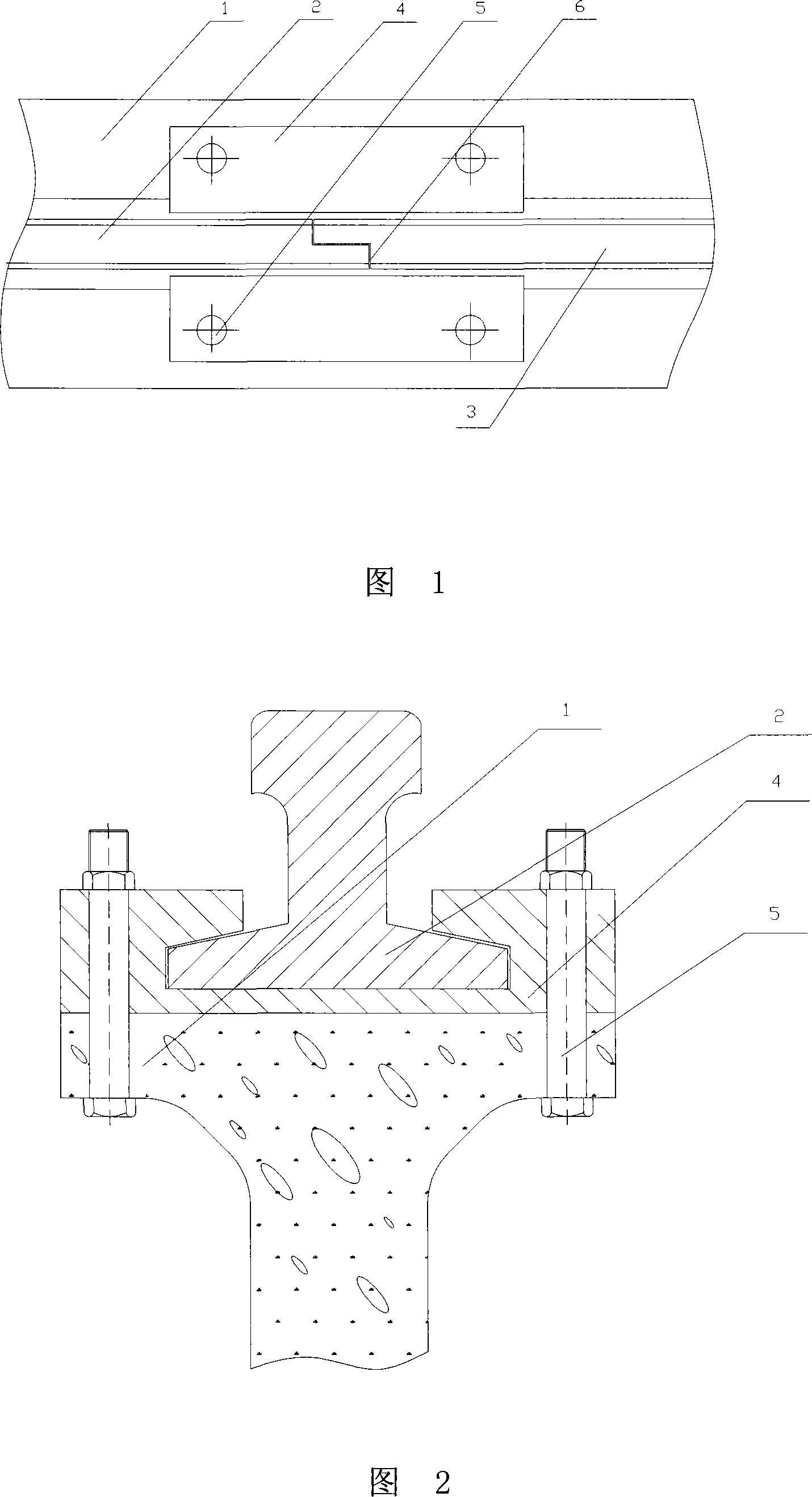

[0023] As shown in Fig. 1 and Fig. 2, the connection method of the track expansion joint of the present invention first places a track 2 on the cement beam 1, puts a dovetail-shaped draw-in groove 4 as a connecting plate at the expansion joint of the track 2, and then Then put another track 3 into the dovetail-shaped slot 4, overlap with the track 2, the track 2 does not move, move the track 3 laterally, adjust the gap distance between the joints of the track 2 and the track 3, and ensure that the L-shaped track expansion joint 6 The distance between the gaps meets the technical requirements of thermal expansion and contraction, and the installation can be completed by tightening the fixing bolts 5 between the L-shaped track expansion joint 6 and the cement beam 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com