Rail differential automatic steering electric horizontal moving cart

An automatic steering and power steering technology, which is applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of ordinary rail-driven electric translation trolleys that cannot run, large track radius at turns, and wear and tear of wheels and tracks. Eliminate the phenomenon of rail gnawing, long service life and small maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

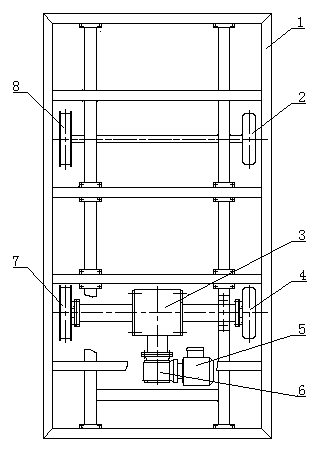

[0007] see figure 1 , the track differential automatic steering electric translation trolley of the present invention includes a frame 1, a drive wheel 4, a drive motor 5 and a reducer 6, and also includes a powerless steering wheel 2, a differential 3, a guide drive wheel 7 and a powerless guide Steering wheel 8, the input shaft of the differential 3 is connected with the output shaft of the speed reducer 6, the left output shaft of the differential 3 is connected with the guide drive wheel 7, the right output shaft of the differential 3 is connected with the The drive wheel 4 is connected, the unpowered steering wheel 8 is installed on the left side of the frame 1, the unpowered steering wheel 2 is installed on the right side of the frame 1, and the differential 3 is a bevel gear differential .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com