RMG cart accurate container location parking and cart synchronization control method

A control method and technology for carts, which are applied in the directions of load hanging components, transportation and packaging, safety devices, etc., can solve the problems of the positioning accuracy not meeting the requirements, affecting the positioning accuracy, and the large amount of engineering, so as to improve the operation efficiency, The effect of reducing running distance and saving running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0039] The invention relates to the technical field of crane cart control and positioning, and discloses a control method for RMG cart precise box parking and cart synchronization, which solves the problems of low positioning accuracy and external factors affecting the positioning system accuracy in the prior art. The impact is great, the cost is relatively high, and the system architecture is relatively complicated. At the same time, it solves the problem of RMG cart synchronization that is not involved in the original technology.

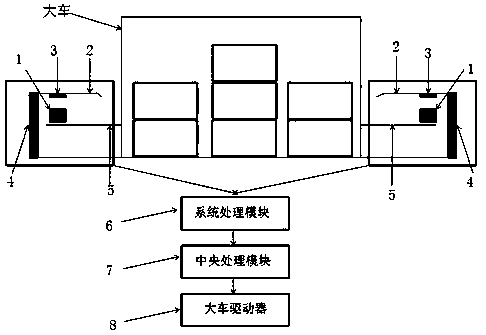

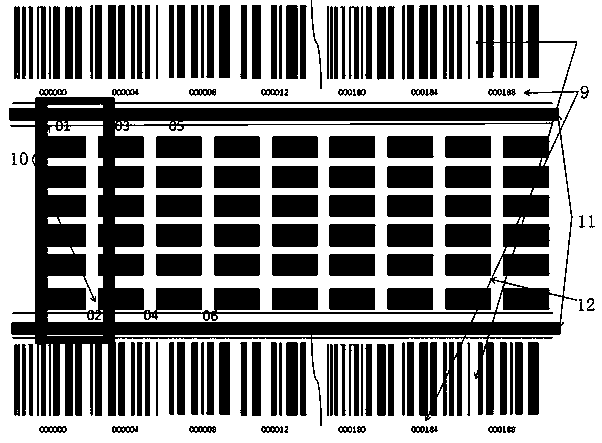

[0040] The control method relies on a preset control system, which includes the following structure:

[0041] A pair of barcode strips 3 extending along the direction of the rails 11 on both sides of the yard 12, a pair of barcode readers 1 that can move with the cart and scan the barcode strip 3, a system processing module 6, a database...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com