Open steel tube and reinforced-concrete combined girder bridge structure

A technology of steel-concrete composite beams and steel pipes, which is applied to bridges, bridge parts, bridge materials, etc., can solve the problems of complex stud preparation and construction processes, the quality of shear connectors cannot be guaranteed, and the load bearing capacity of a single shear connector Low force and other problems, to achieve the effect of easy guarantee of processing quality, simple structure and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

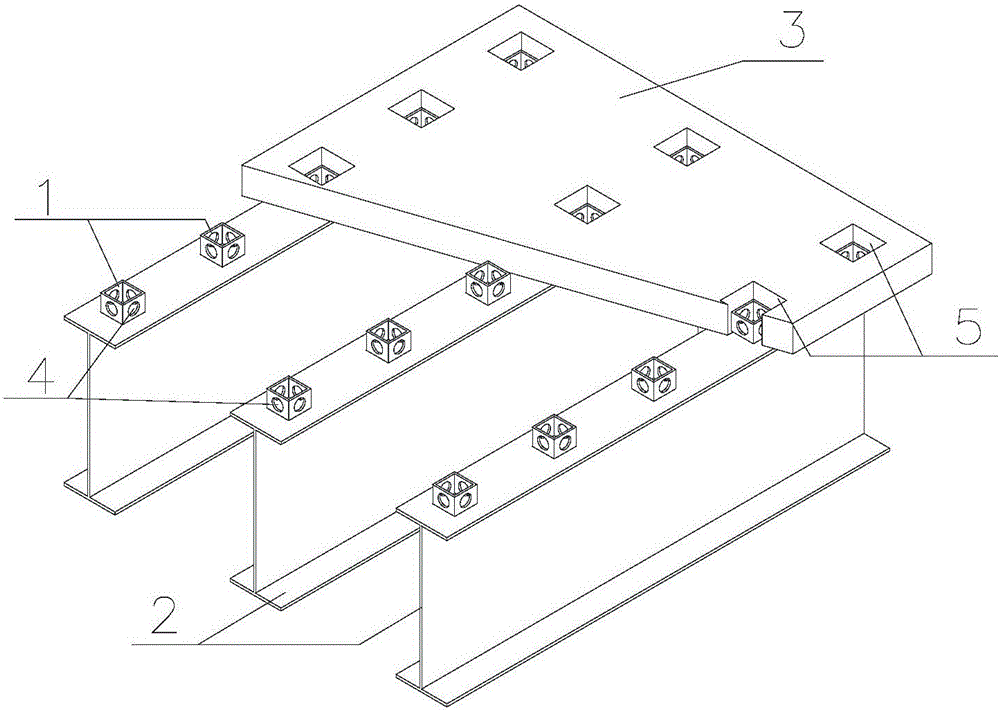

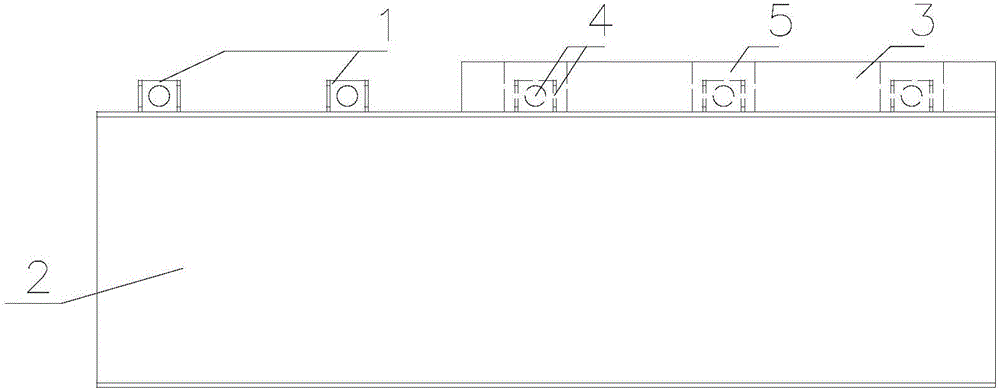

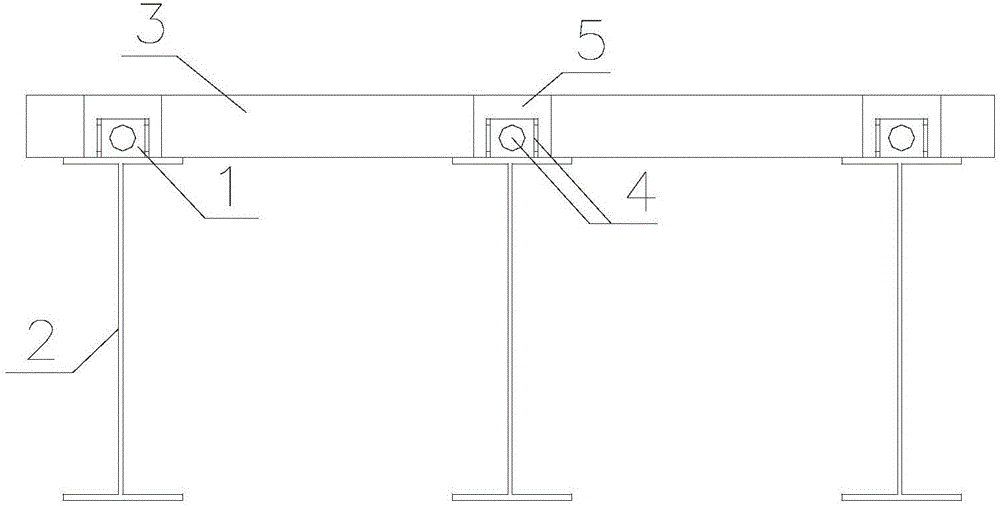

[0029] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes a steel main girder 2, a concrete bridge deck 3 and a perforated steel pipe connector 1; Above, the cast-in-place bridge deck is used, and the combined structure is formed through the steel pipe connector 1 and the steel beam 2, and they are jointly stressed.

[0030] In this embodiment, multiple steel girders 2 are arranged along the length direction and all of them are arranged on a horizontal plane, and the steel girders 2 are welded I-beams.

[0031] Such as figure 1 , figure 2 , image 3 As shown, in this embodiment, the concrete bridge deck 3 is erected on the steel girder 2, and the prefabricated bridge deck structure is adopted, and the concrete bridge deck 3 is reserved for pouring concrete at the position of the steel pipe connector with holes. The pouring groove 5 is connected with the steel girder 2, and the concrete pouring groove 5 is matched with the perforated steel p...

Embodiment 2

[0037] In this example, if Figure 5 with Image 6 As shown, the difference from Example 1 is that: the steel pipe connector 1 is a steel pipe structure in the form of a round steel pipe.

[0038] In this embodiment, the steel main girder 2 is a steel box girder.

[0039] In this embodiment, the steel pipe connector 1 is only provided with holes 4 in the lateral direction.

[0040] In this embodiment, the structures and connections of other parts are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com