Universal type rotor core overlaying tool and method

A rotor core and stacking tooling technology, applied in the field of rotor core stacking, can solve the problems of increasing the time of the rotor core stacking process, increasing the working stroke of the hydraulic press, and reducing production efficiency, so as to shorten the operating hours and increase the production efficiency. Large compression area, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with non-limiting examples.

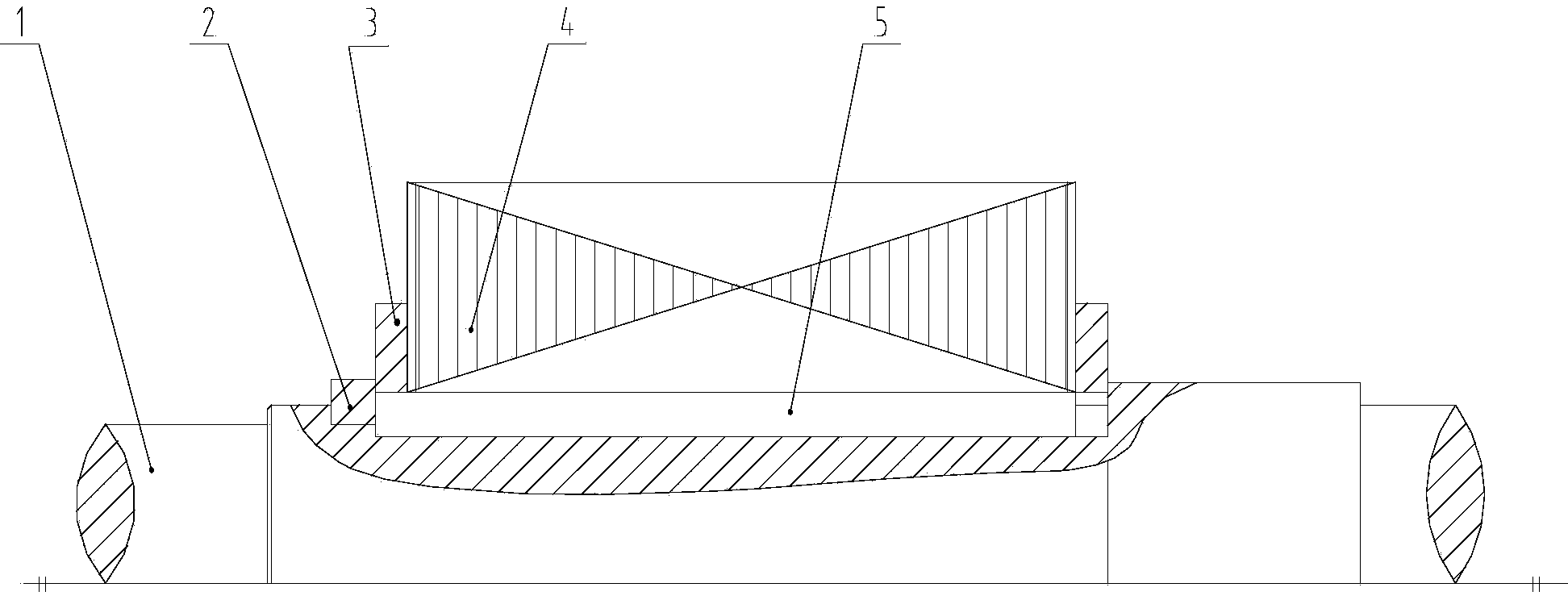

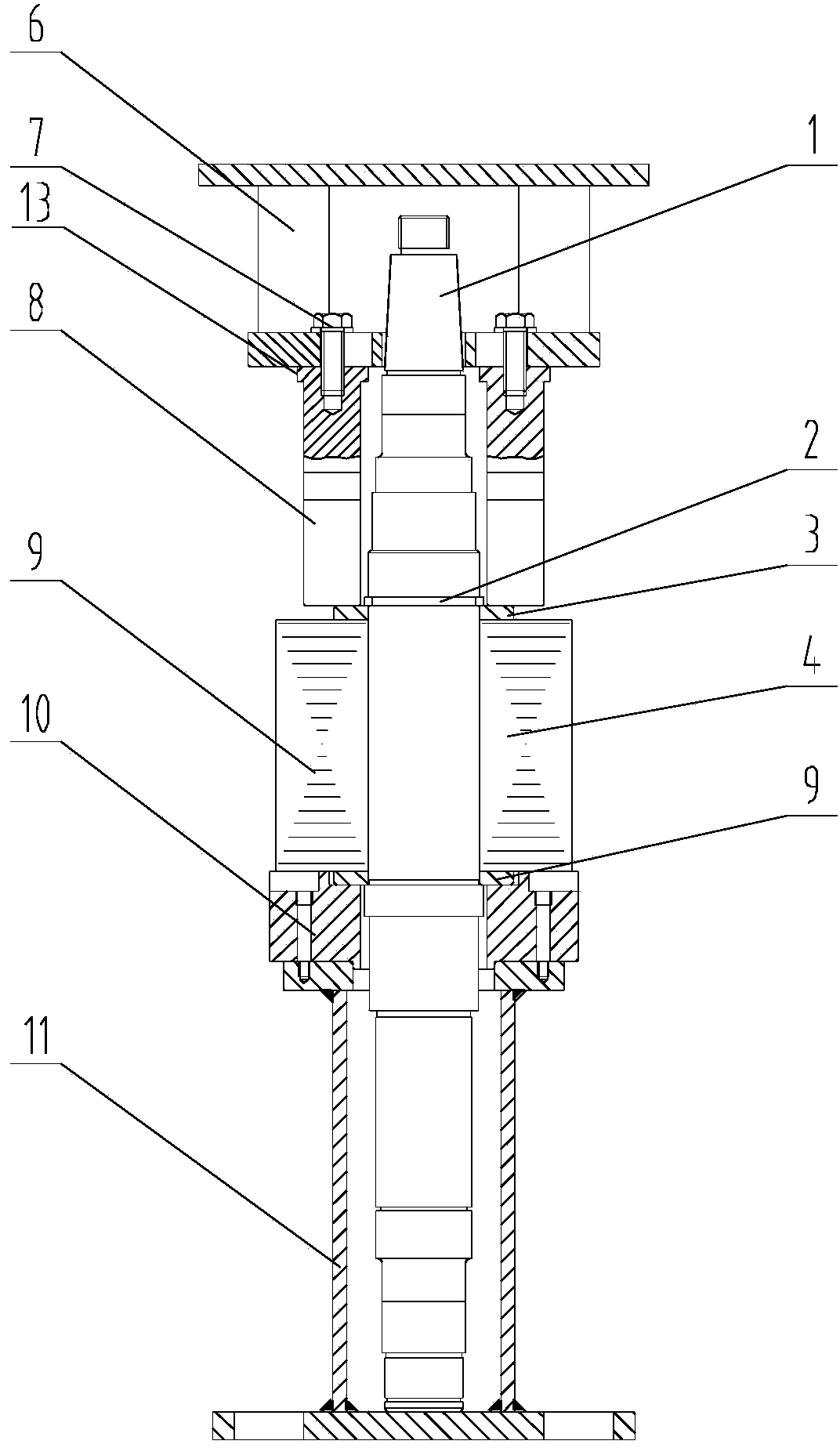

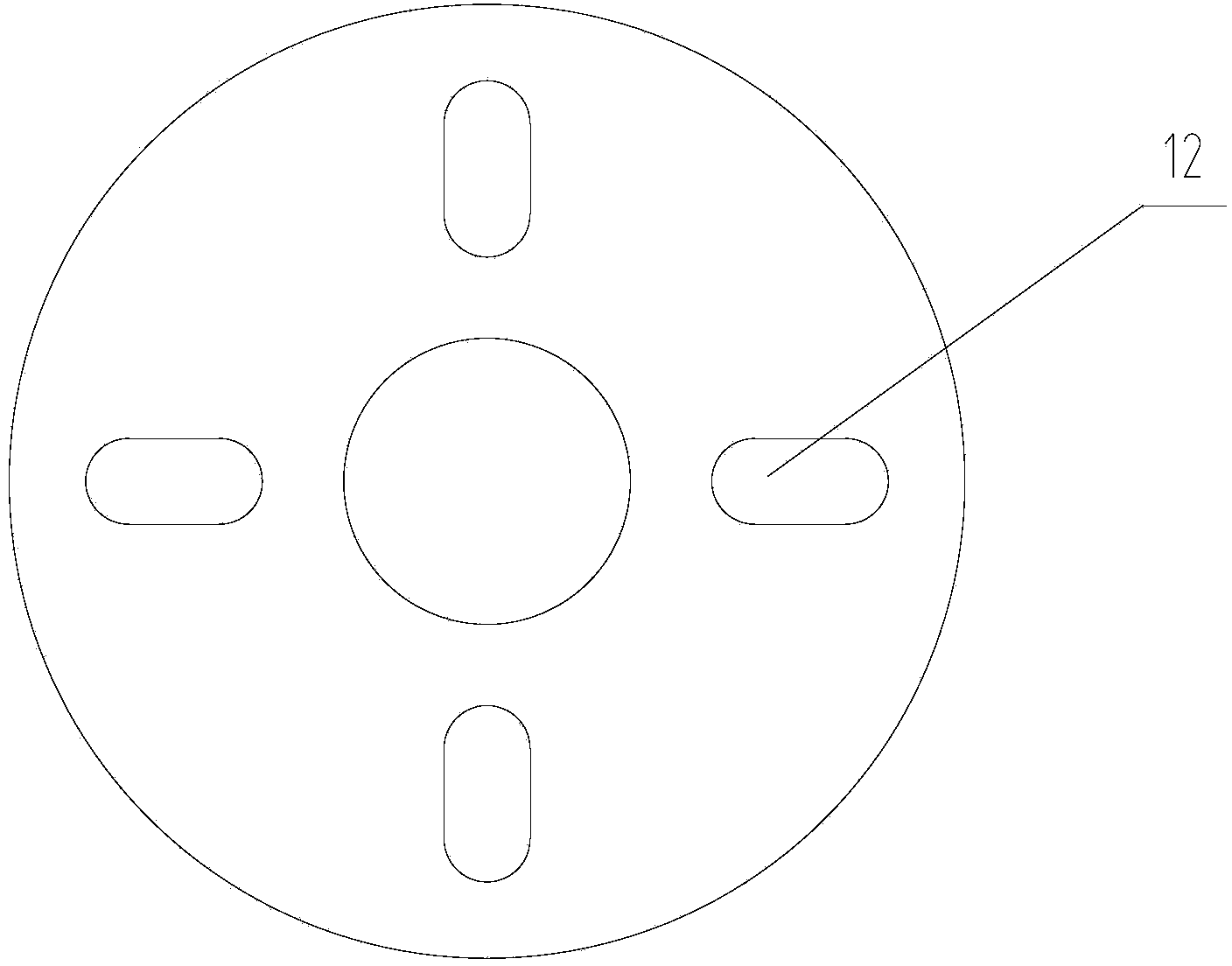

[0030] As shown in the figure: the general-purpose rotor core lamination tooling of the present invention includes a pressure applying part and a pressure receiving part, the mandrel 1 is located between the pressure applying part and the pressure receiving part, and the mandrel 1 is fixed by the rotor core key 5 The rotor core 4; the pressure exerting parts include a pressure table 6 and a pressure column 8, the pressure table 6 and the pressure column 8 are connected through the waist hole 12 and the fixing bolt 7, and the top of the pressure column 8 has a boss 13; the pressure bearing parts include a base 11, The base transition plate 10, the upper rotor retainer 3, the lower rotor retainer 9, the upper and lower ends of the rotor iron core 4 are installed with the rotor retainer, the upper rotor retainer 3 is installed with the fixed key 2 at the end of the rotor core,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com