Hobbing cutter rest rotating device capable of locating accurately

A technology of accurate positioning and rotary devices, which is applied in the direction of gear tooth manufacturing devices, gear teeth, gear cutting machines, etc., can solve the problems of low rotary precision and scrapped test cut parts, and achieve high rotary precision, simple structure and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

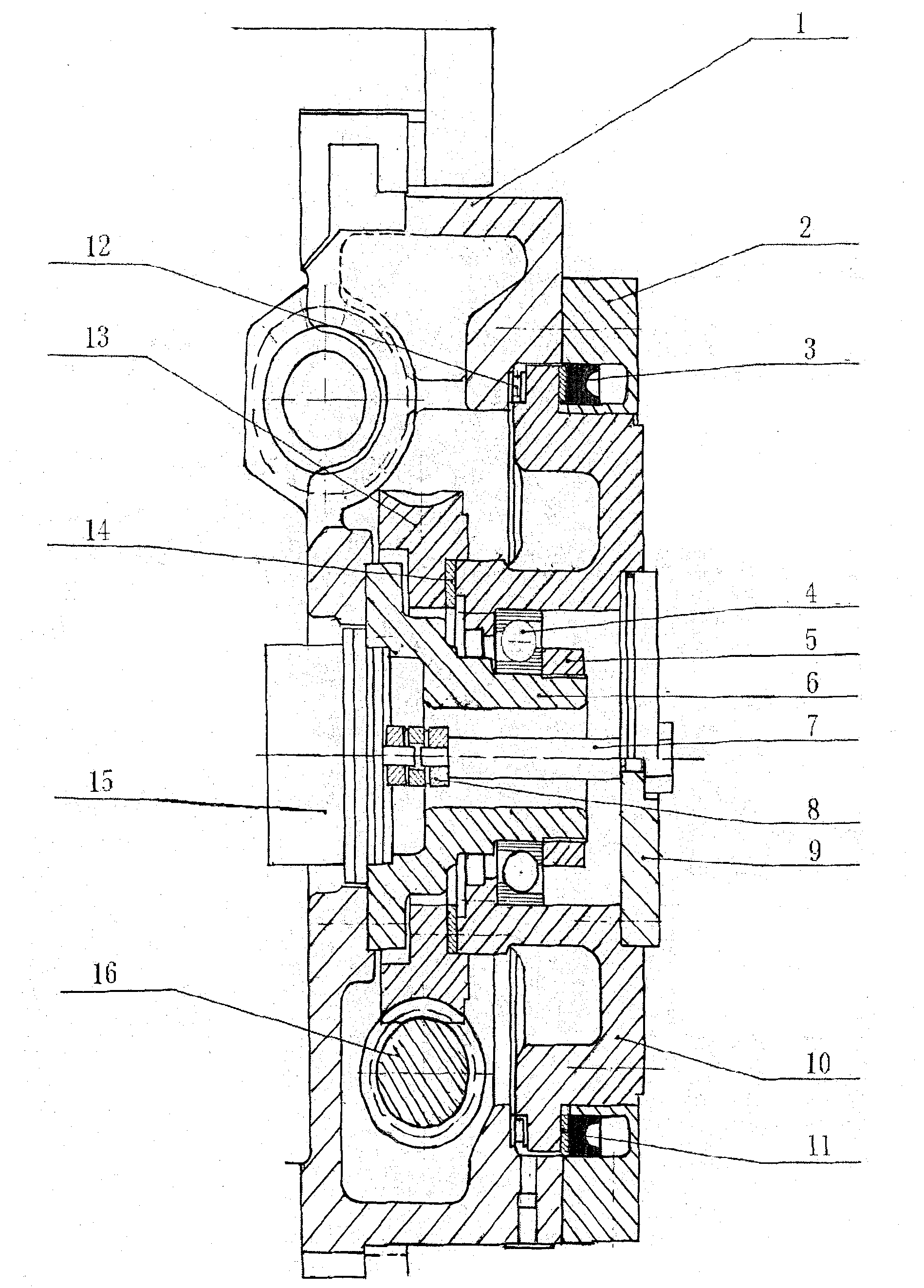

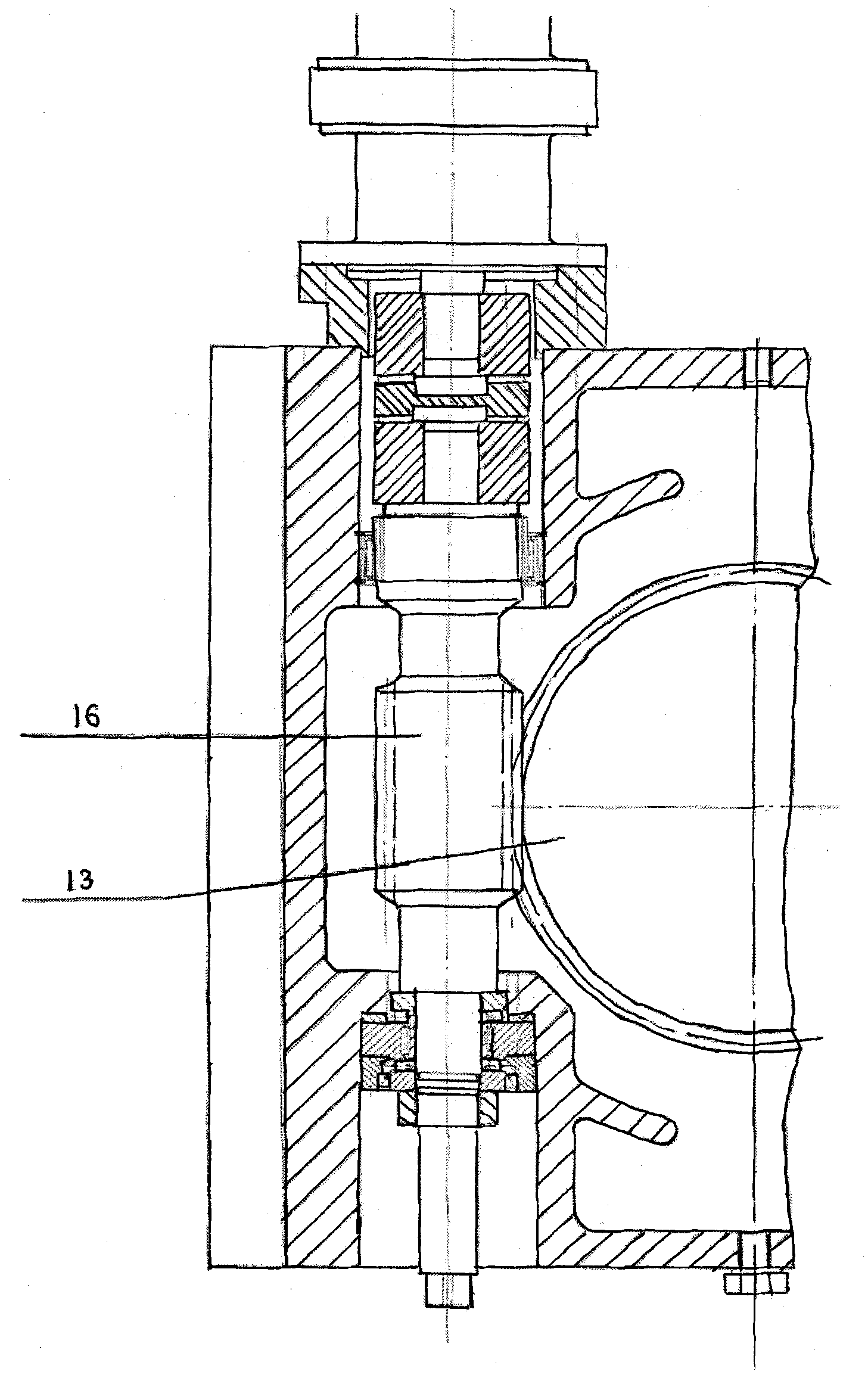

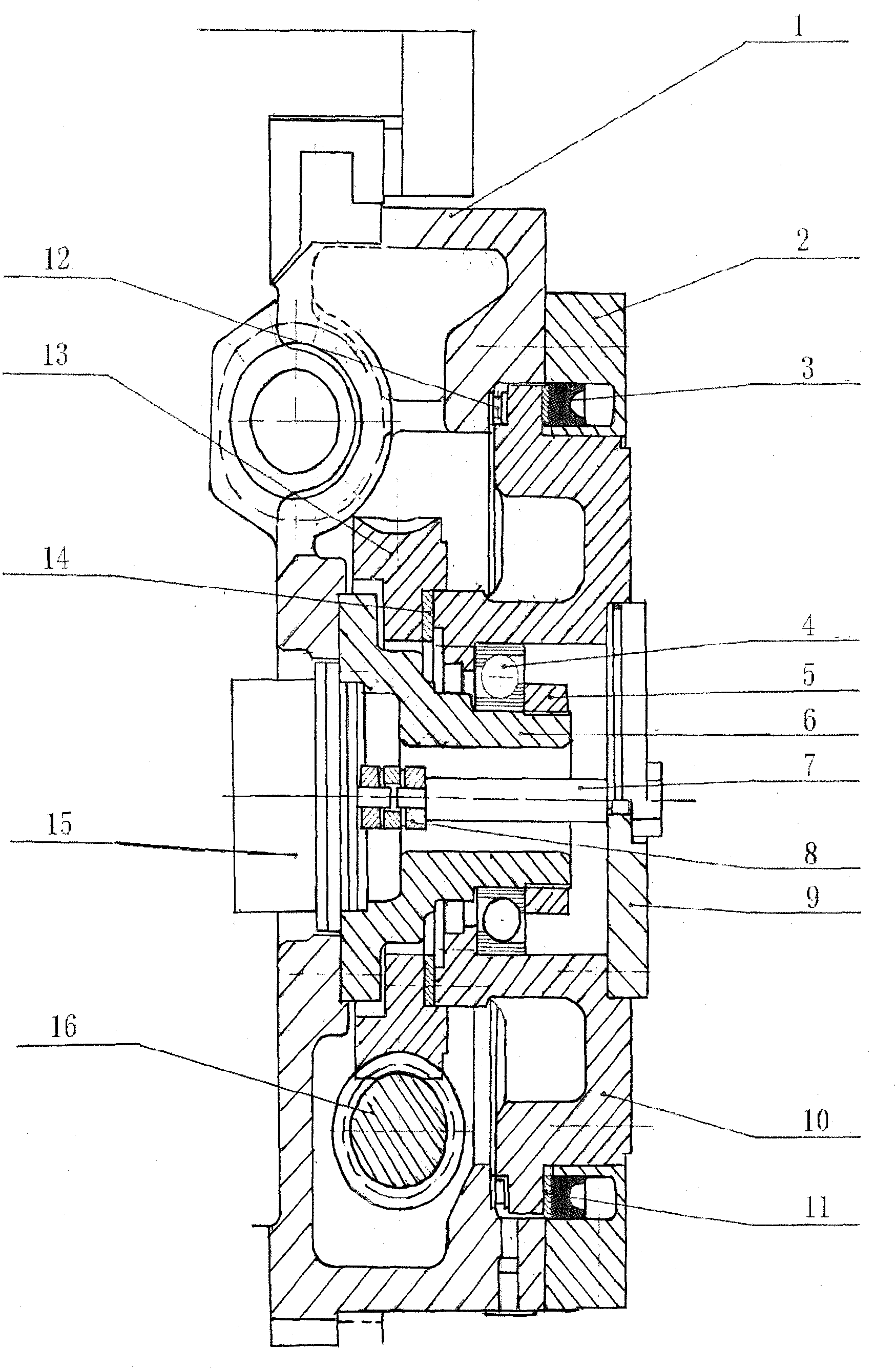

[0014] Such as figure 1 with figure 2 shown.

[0015] A gear hobbing tool holder rotary device capable of accurate positioning, comprising a housing (1), the upper end of the housing (1) has a circular hole, and the inner wall of the circular hole has an inwardly protruding ring platform, A plane bearing (12) is arranged on the said ring platform, and a rotary part (10) is installed on the said plane bearing (12), and an outer ring platform is arranged on the outer wall of the upper end of the said rotary part (10); the outer ring platform An annular plate (11) is placed on it.

[0016] The circular pressing plate (2) is provided with an annular groove, and a sliding fit annular piston (3) is arranged in the annular groove, and the circular pressing plate (2) is reversely buckled and pressed on the annular plate (11) of the outer ring platform , the opening of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com