Fe3+ loading composite catalyst, preparation method of catalyst and dewatering pretreatment method for Fenton-like sludge

A composite catalyst, sludge dewatering technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc. The effect of preventing precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) a kind of Fe 3+ The preparation method of supported composite catalyst comprises the following steps:

[0045] Step 1: Sludge Pretreatment

[0046] The sludge is the remaining sludge with a water content of 80% obtained after being filtered by a plate and frame filter press, and then dried and ground, and passed through a 60-mesh sieve to obtain sludge particles;

[0047] Step 2:

[0048] The kaolin used in this embodiment is clay mineral; according to the mass ratio, sludge particles: kaolin = 5:1, the sludge particles are mixed with kaolin to obtain a mixture;

[0049] To the mixture, add FeCl with a substance concentration of 30mmol / L 3 solution, while adding EDTA-2Na with a mass of 0.5% of the sludge particles, stirring evenly, and granulating to prepare ceramsite with a diameter of 5mm; wherein, by volume ratio, the mixture: FeCl 3 Solution = 1:1.5;

[0050] Step 3: Drying and Calcination

[0051] Dry the prepared ceramsite. Then place it in an oven for ...

Embodiment 2

[0058] (1) a kind of Fe 3+ The preparation method of supported composite catalyst comprises the following steps:

[0059] Step 1: Sludge Pretreatment

[0060] Sludge is to remove Fe in embodiment 1 3+ The dewatered pretreated sludge loaded with composite catalyst, this sludge is passed through Fe 3+ Supported composite catalyst with H 2 o 2 After the composition of the Fenton-like reagent pretreatment, and then through the removal of Fe 3+ The composite catalyst is loaded and dehydrated by suction filtration, and the moisture content of the mud cake is 62.7%. After the sludge is dried and ground, it passes through a 60-mesh sieve to obtain sludge particles;

[0061] Step 2:

[0062] The attapulgite used in this example is a viscous mineral; according to the mass ratio, sludge particles:attapulgite=5:1, the sludge particles and attapulgite are mixed to obtain a mixture;

[0063] To the mixture, add FeCl with a substance concentration of 40mmol / L 3 solution, while addin...

Embodiment 3

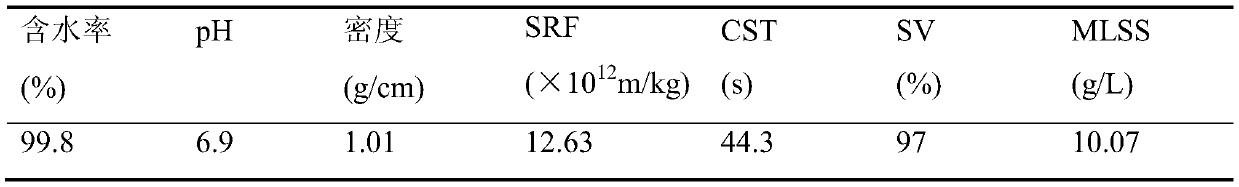

[0071] With the Fe reclaimed in embodiment 1 3+ The loaded composite catalyst is reused, and it and H 2 o 2 Reagent formed Fe 3+ The method for the sludge dewatering pretreatment of the class Fenton reagent specifically comprises the following steps:

[0072] (1) Fe used in Example 1 3+ The loaded composite catalyst is separated from the sludge after dewatering pretreatment by filtration, washed and dried with deionized water, and sent to the next group of sludge dehydration pretreatment experiments (experimental conditions are the same as in Example 1);

[0073] (2) Add the recycled Fe to the test sludge 3+ supported composite catalyst, where H 2 o 2 (30%) The concentration of the substance whose dosage accounts for the volume of the wet sludge is still 90mmol / L, under the condition of the original pH (about 6.9) of the sludge, 40r / min is used for sludge pretreatment for 90min, and the dehydration pretreatment is obtained. sludge.

[0074] (3) Treatment effect: In the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com