Dehydration equipment

A technology for dehydration equipment and water outlet holes, which is applied in lighting and heating equipment, drying solid materials, dryers, etc., and can solve the problems of blocked outlets and pressure plates that cannot effectively achieve dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

[0029] In each drawing of the present invention, for convenience of illustration, some dimensions of structures or parts are exaggerated relative to other structures or parts, and therefore, are only used to illustrate the basic structure of the subject matter of the present invention.

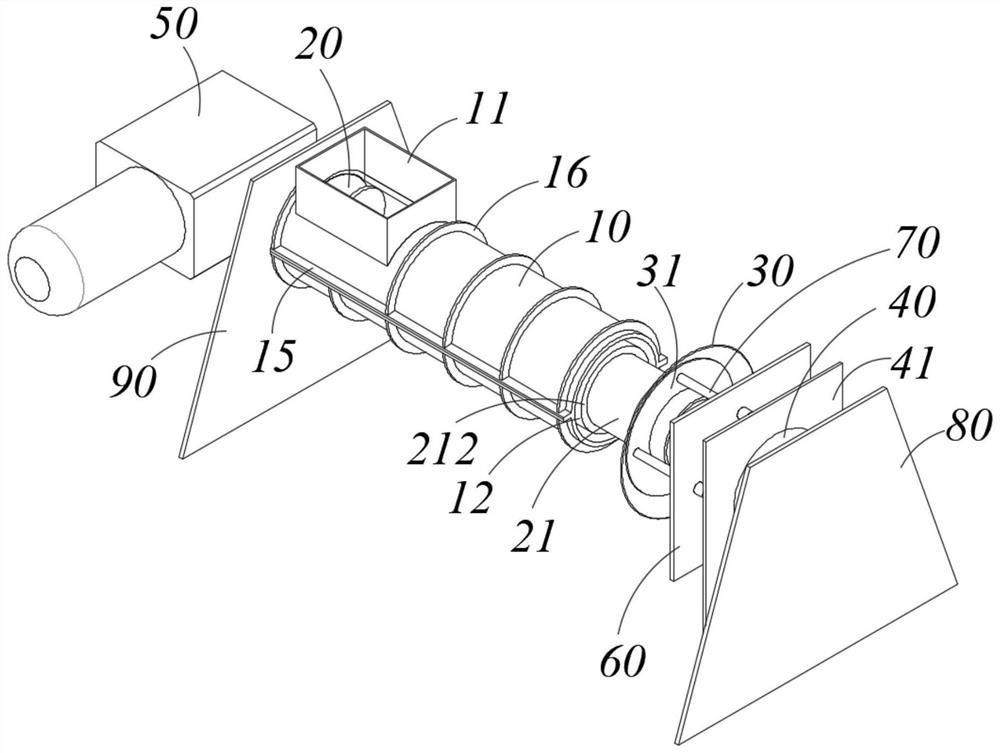

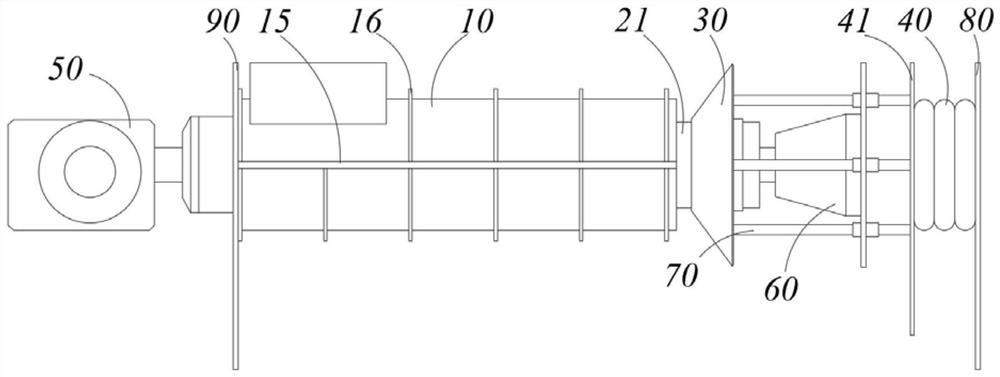

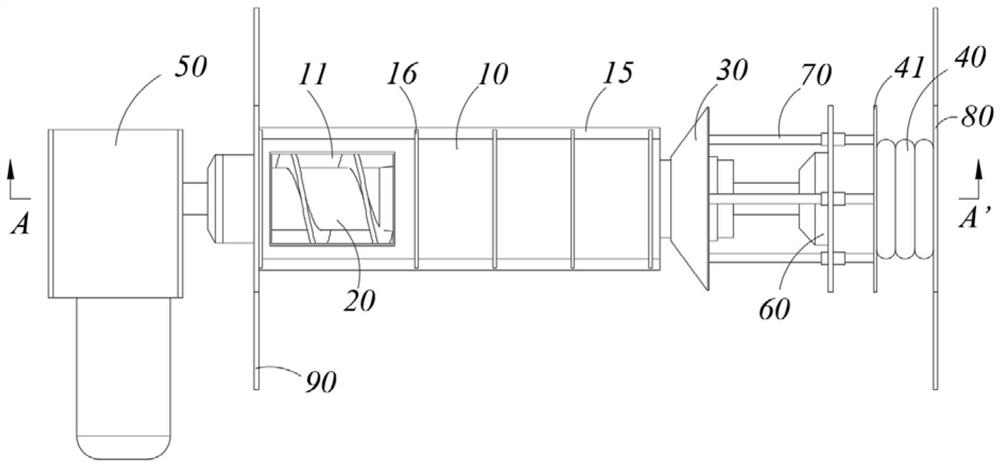

[0030] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, one embodiment of the present invention provides a kind of dehydration equipment, comprising:

[0031] A sieve cylinder 10 is provided with an inlet 11 and an outlet 12 on the sieve cylinder 10 . Materials can enter the inside of the screen dru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com