Horizontal type paper-film dehydration equipment

A dewatering equipment, a horizontal technology, applied in the field of horizontal dewatering equipment for membrane paper, can solve the problems of increasing production cost, wasting production time, unable to meet production, etc., and achieving the effect of increasing output and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

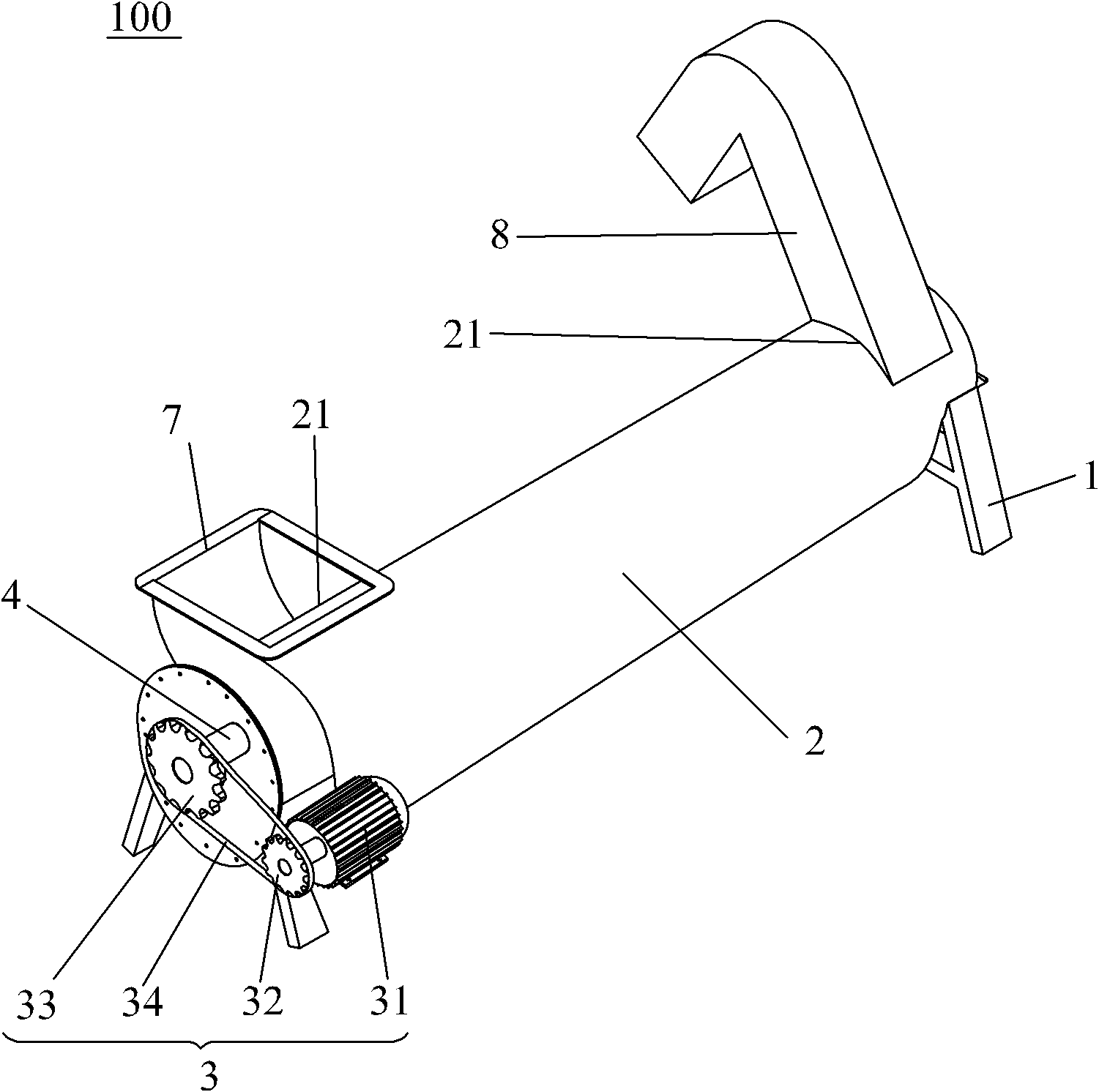

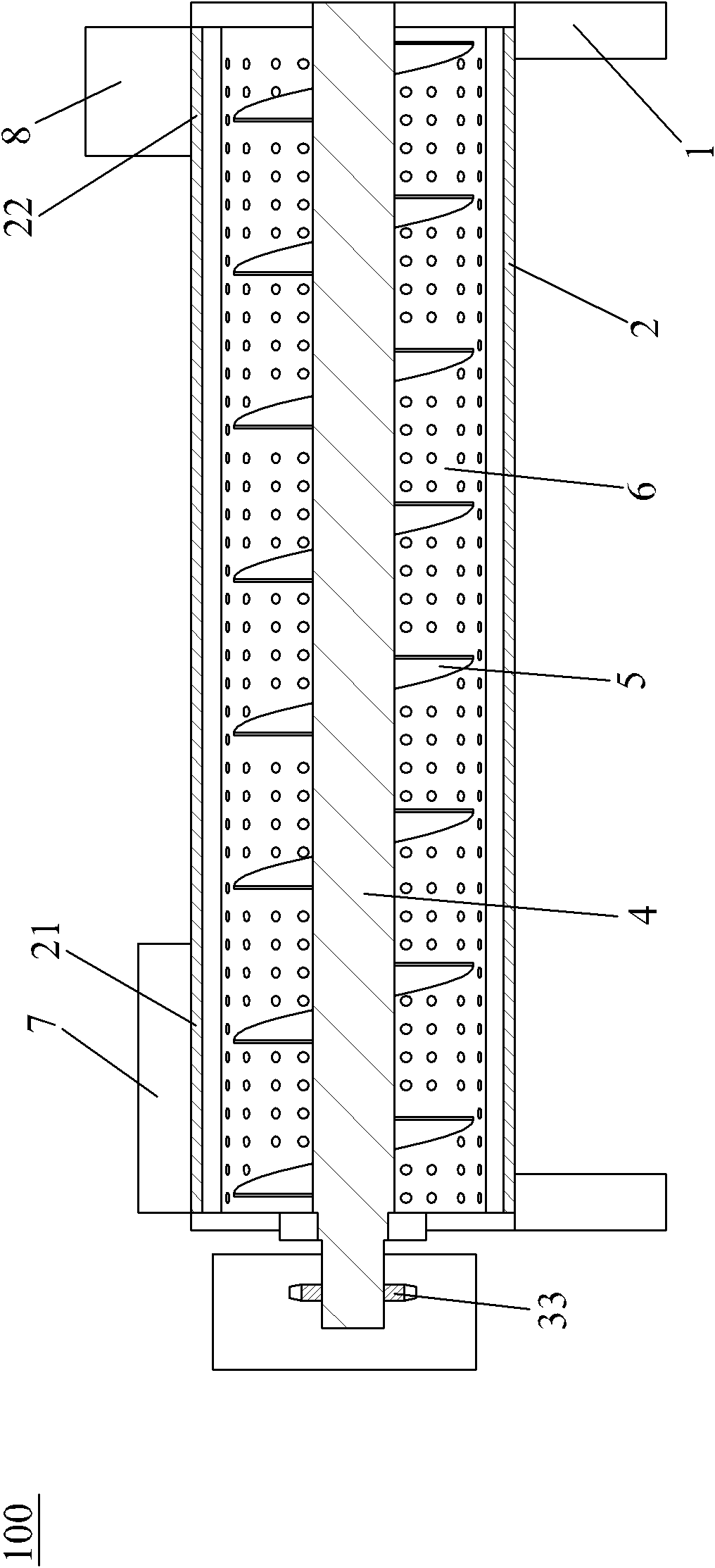

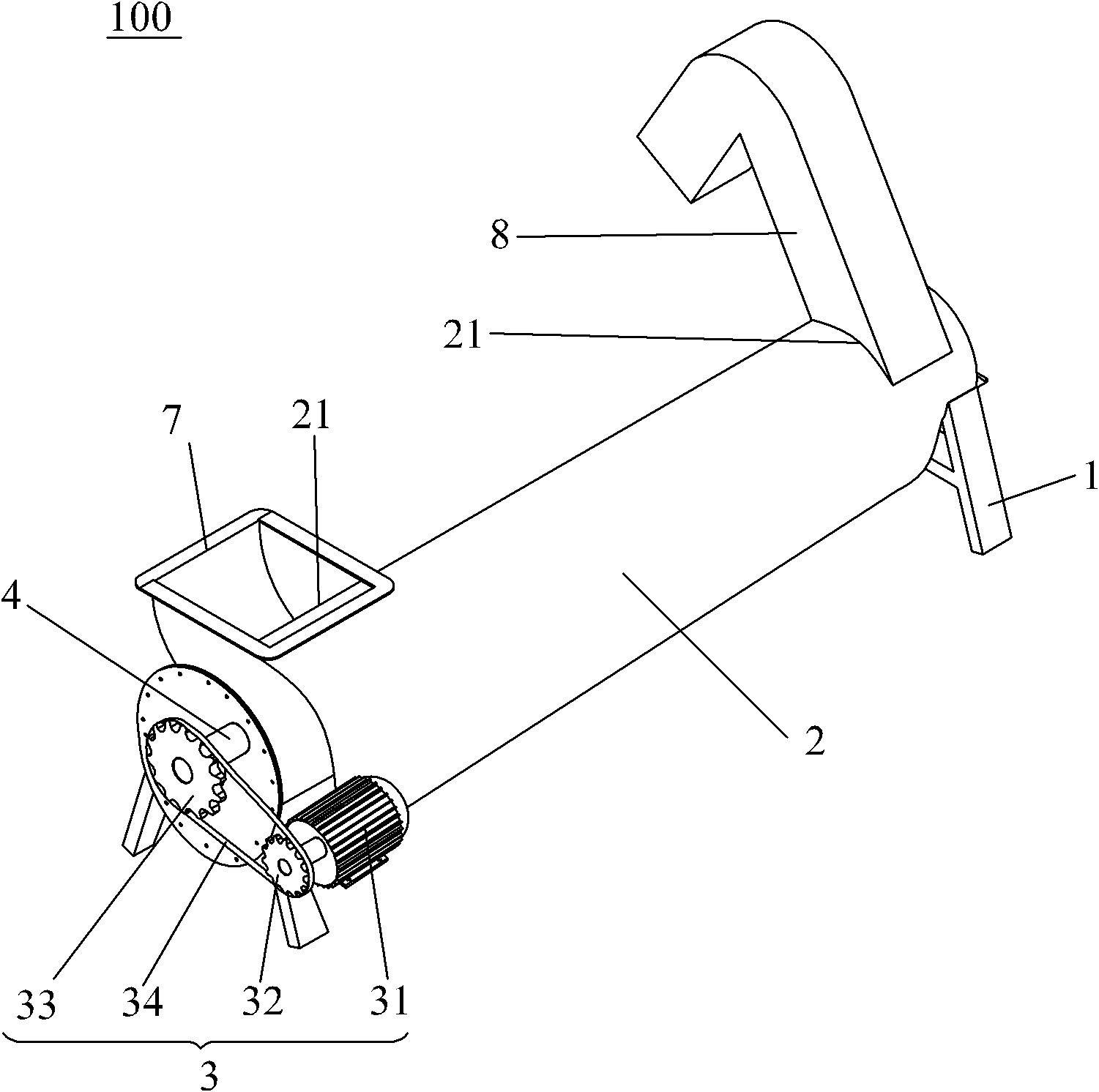

[0014] Such as figure 1 and figure 2 As shown, the film paper horizontal dewatering equipment 100 of the present invention includes a frame 1, a dewatering barrel 2, a driving mechanism 3, a main shaft 4, a blade 5, a cylindrical separating screen 6, a blanking hopper 7, and a discharge hopper 8. The dewatering bucket 2 is cylindrical and horizontally fixed on the frame 1, and the dewatering bucket 2 is cylindrical and can accommodate the separating screen 6 so that the separating screen 6 is easy to install. Compact, the dewatering barrel 2 is provided with an inlet 21 at one end and an outlet 22 at the other end. Both the inlet 21 and the outlet 22 are in communication with the separating screen 6. The separation screen 6 is arranged inside the dehydration barrel 2 and is made of stainless steel, which can prevent the separation screen 6 from rusting, is wear-resistant and durable, and generates low noise during operation. The main shaft 4 is built in the separating screen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com