Light-emitting diode dehydrator

A diode and dehydrator technology, applied in dryers, non-progressive dryers, drying solid materials, etc., can solve the problems of poor effect and incomplete dehydration, and achieve the effect of preventing oxidation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

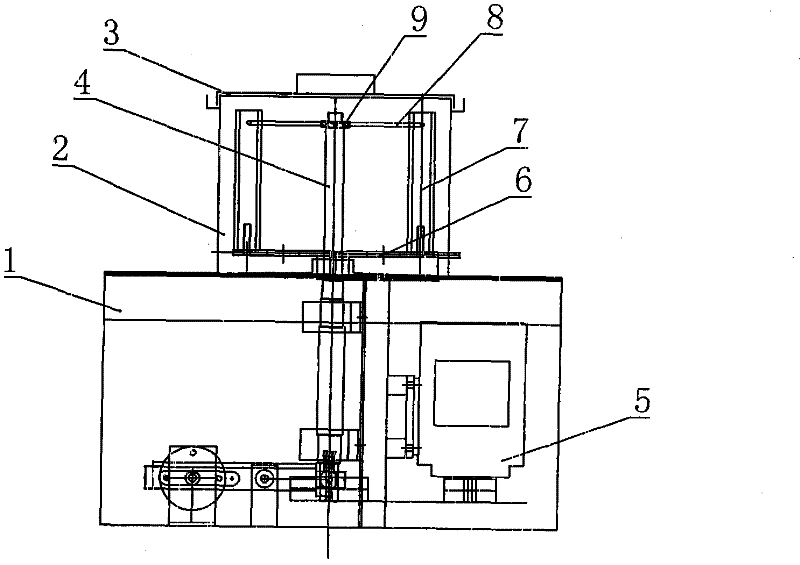

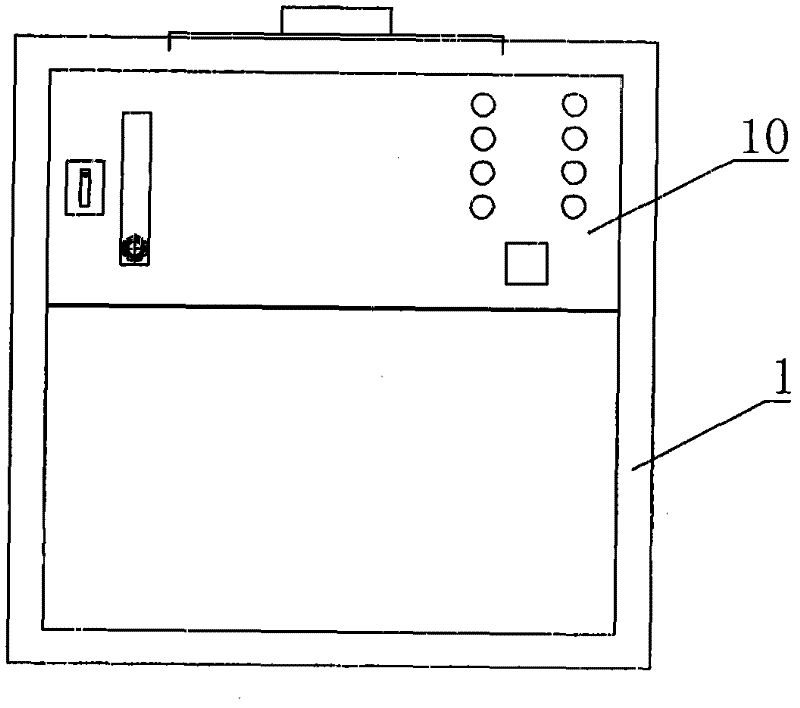

[0015] Such as figure 1 , 2 , 3, including frame 1, dehydration outer barrel 2, barrel cover 3, rotating shaft 4, drive motor 5,

[0016] The top of the above-mentioned frame 1 is fixed with a dehydration outer barrel 2, the top of the dehydration outer barrel 2 is covered with a barrel cover 3 for sealing, and the side wall of the outer barrel is provided with an air inlet through which nitrogen gas can be introduced to prevent diode It is oxidized in contact with air during dehydration.

[0017] Rotating shaft 4 is vertically arranged on frame 1 by bearing and bearing seat, and its top stretches into the center of dehydration outer barrel 2, and the end is connected with drive motor 5 by belt transmission.

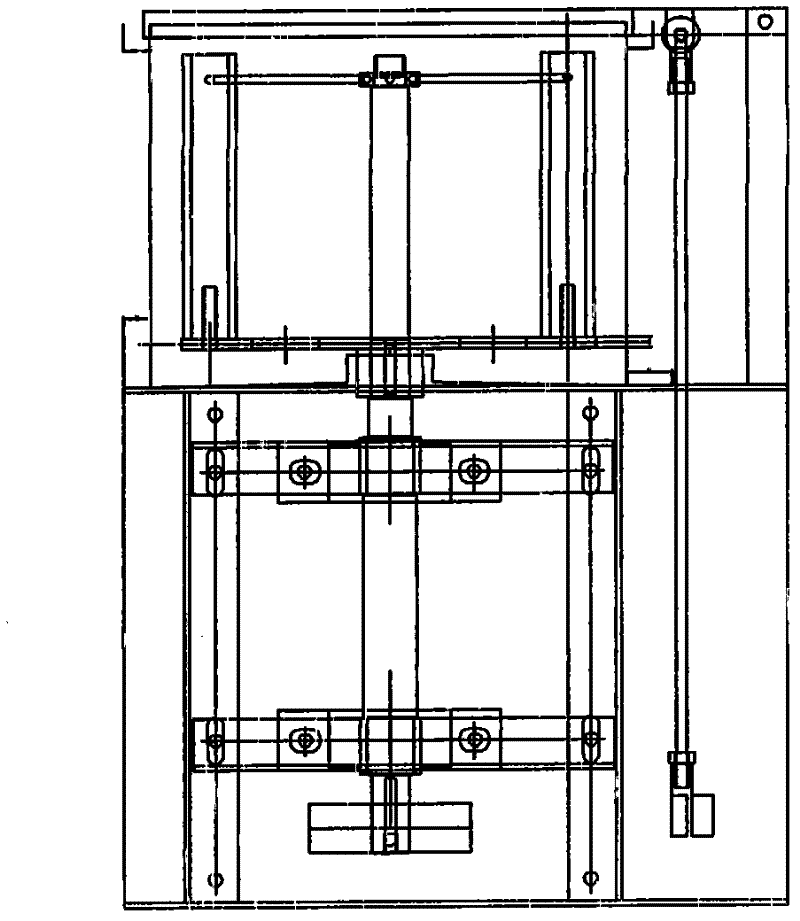

[0018] The dehydration liner is set in the dehydration outer barrel 2, and is used to install the diode pickling mold that needs dehydration. It mainly includes a bottom plate 6, a vertical support 7, six vertical support 7 evenly distributed around the circular bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com