Bottle cleaning equipment and cleaning process thereof

A bottle body and equipment technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as inability to clean the bottle body, and achieve the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

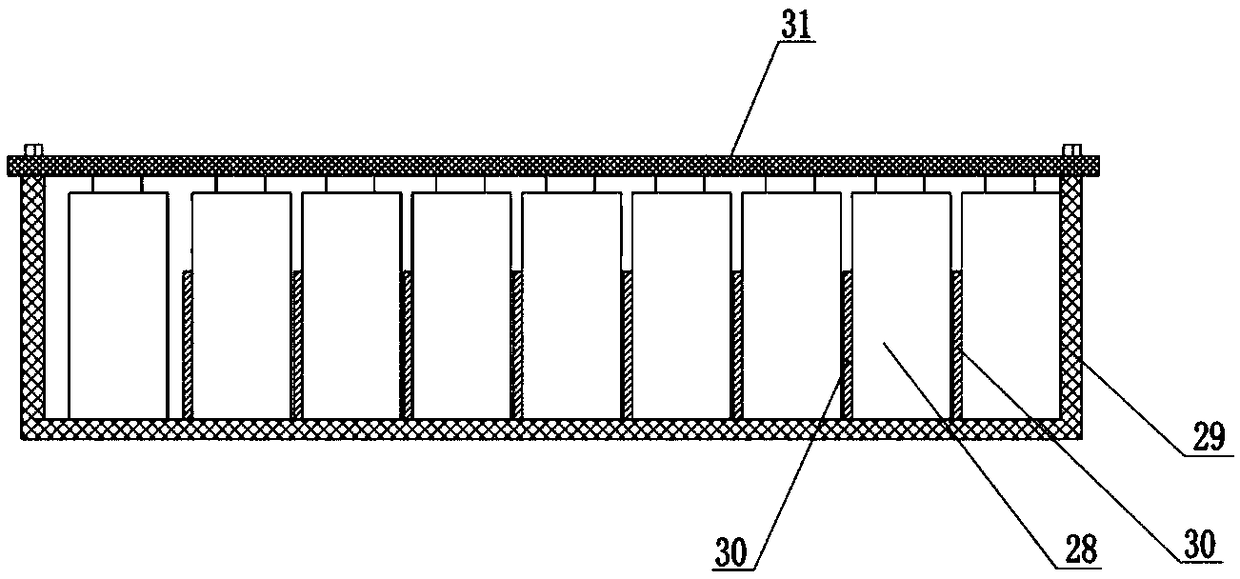

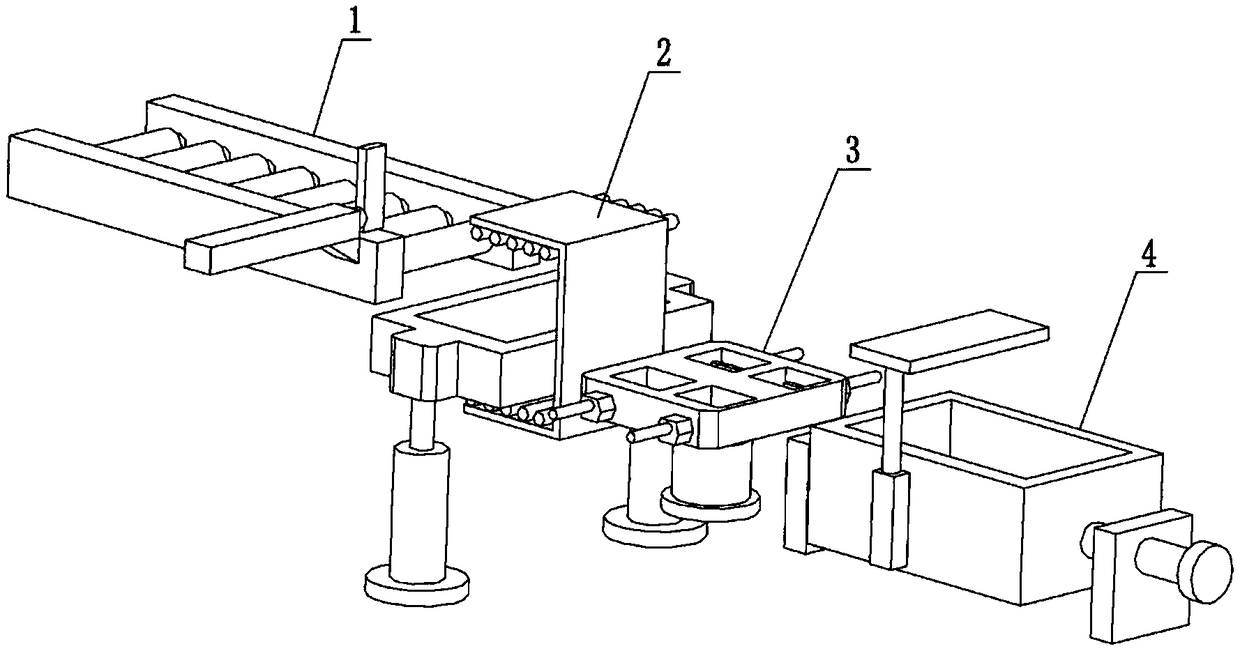

[0037] Such as Figure 2-7 Shown, a kind of equipment that is used for bottle body cleaning, it comprises conveying device 1, spray cleaning device 2, bottle outer surface dehydration device 3 and bottle inner surface dehydration device 4 that are arranged sequentially from left to right.

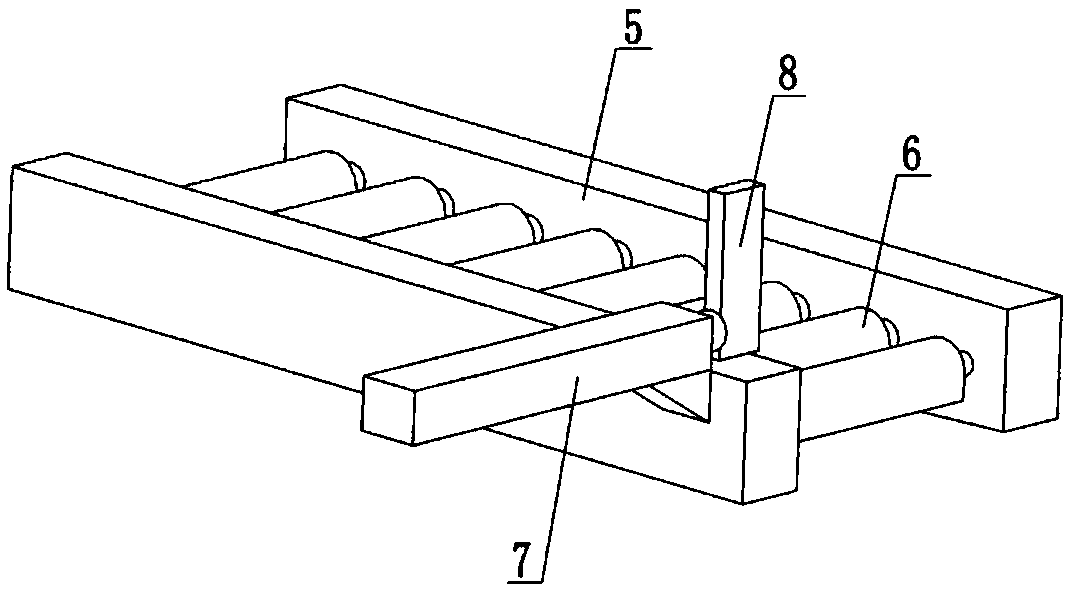

[0038] The conveying device 1 includes a frame 5, a roller 6, an intercepting cylinder 7 and a baffle plate 8. A plurality of rollers 6 are installed in the frame 5 and rotated along its length direction through a rotating shaft, and the intercepting cylinder 7 is fixedly installed on the frame. The top of 5 is arranged parallel to the drum 6, the baffle plate 8 is fixed on the piston rod of the intercepting cylinder 7, a chain is installed between the rotating shafts of two adjacent drums 6, and any rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com