Water-based environment-friendly cleaning method and cleaning device of soldering flux on radar electronic module

A technology of electronic components and flux, which is applied in the field of automated radar electronic batch production, can solve problems such as high reliability requirements, hidden dangers to personnel safety, and general cleaning effect, so as to avoid secondary pollution, high-efficiency rinsing effect, and good cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

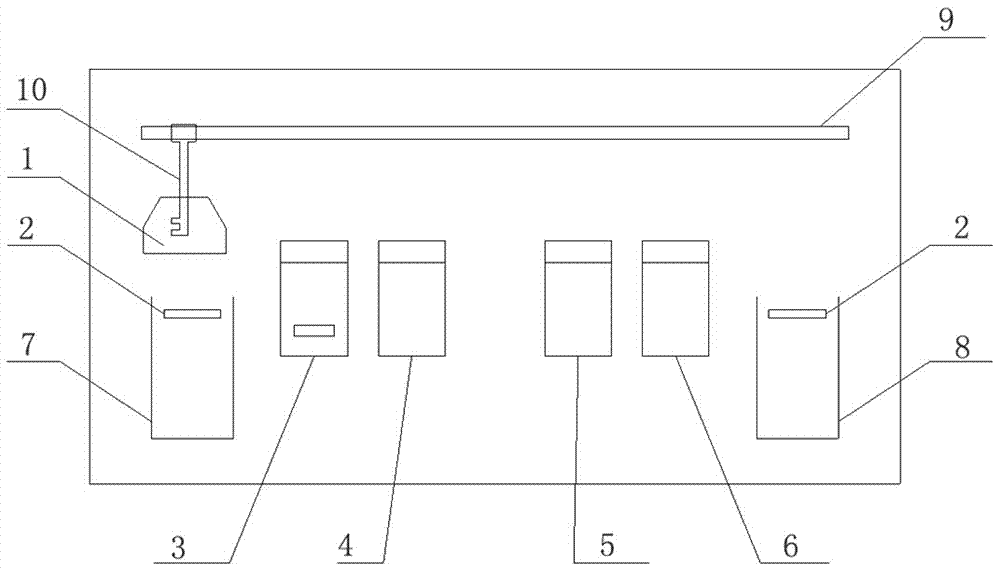

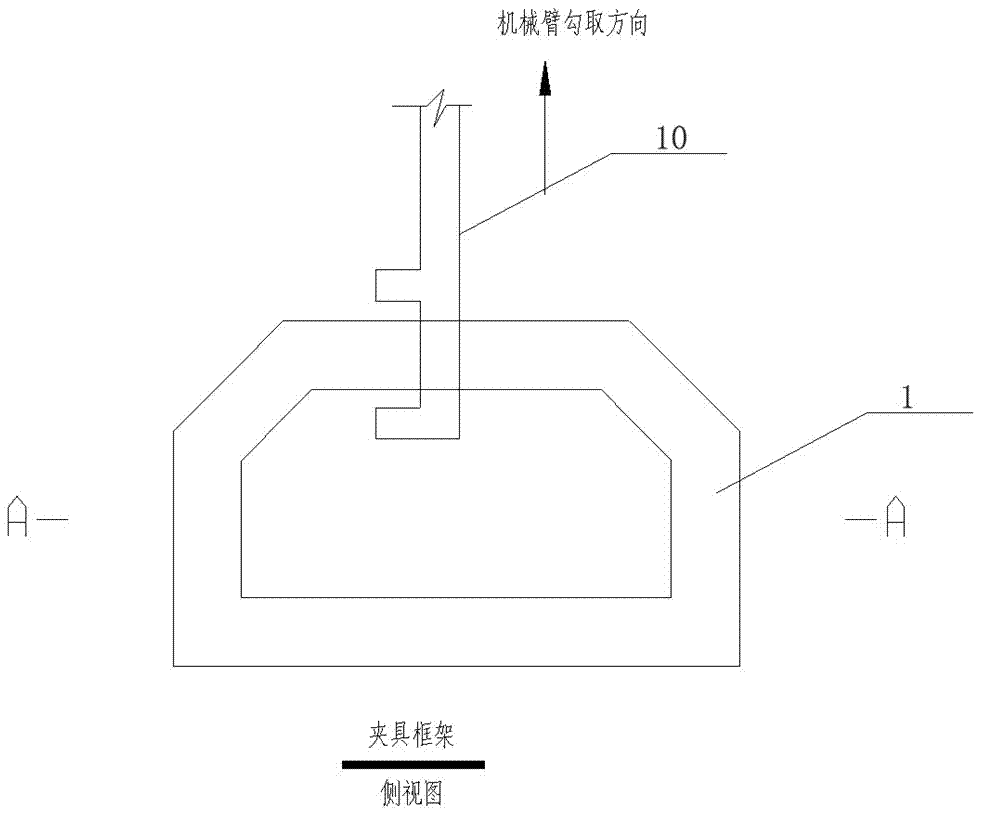

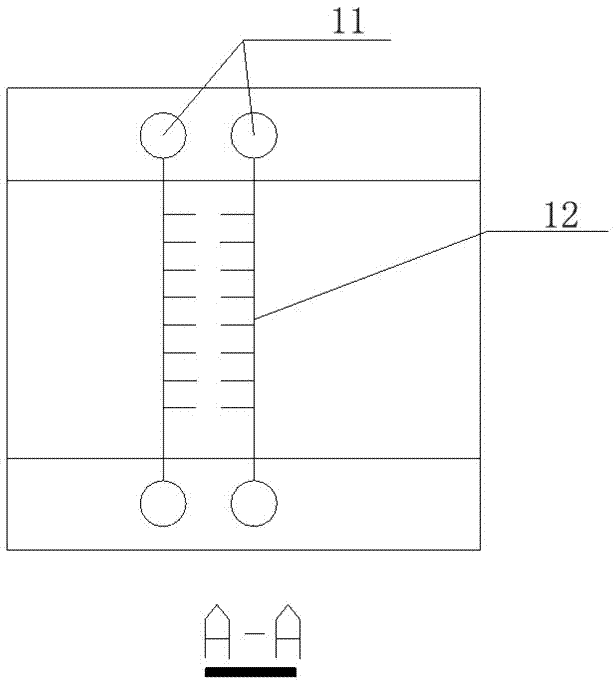

[0052] see figure 1 with Figure 9 , the cleaning device includes a cleaning fixture 1, a conveyor belt 2, a immersion ultrasonic jet cleaning mechanism 3, a reverse spray rinsing mechanism 4, a solvent dehydration bubbling mechanism 5, a drying mechanism 6, a loading table 7 and an unloading table 8, a mobile Mechanism 9 and suspension hook 10.

[0053] The cleaning object is the radar electronic components of the relevant connectors that have been assembled and welded.

[0054] The water-based environmental protection cleaning operation steps for the flux generated during the welding process of radar electronic components are as follows:

[0055] (1) Clamping the radar electronic components to be cleaned

[0056] Clamp and fix 100 radar electronic components A to be cleaned on the cleaning fixture 1, and send them to the loading table 7;

[0057] The arrangement spacing between adjacent radar electronic components to be cleaned is 5cm.

[0058] (2) soaking ultrasonic je...

Embodiment 2

[0070] see figure 1 with Figure 9 , the cleaning device includes a cleaning fixture 1, a conveyor belt 2, a immersion ultrasonic jet cleaning mechanism 3, a reverse spray rinsing mechanism 4, a solvent dehydration bubbling mechanism 5, a drying mechanism 6, a loading table 7 and an unloading table 8, a mobile Mechanism 9 and suspension hook 10.

[0071] The cleaning object is the radar electronic components of the relevant connectors that have been assembled and welded.

[0072] The water-based environmental protection cleaning operation steps for the flux generated during the welding process of radar electronic components are as follows:

[0073] (1) Clamping the radar electronic components to be cleaned

[0074] Clamp and fix 10 radar electronic components B to be cleaned on the cleaning fixture 1, and send them to the loading table 7;

[0075] The spacing between adjacent radar electronic components to be cleaned is 10cm.

[0076] (2) soaking ultrasonic jet cleaning ...

Embodiment 3

[0088] see figure 1 with Figure 9 , the cleaning device includes a cleaning fixture 1, a conveyor belt 2, a immersion ultrasonic jet cleaning mechanism 3, a reverse spray rinsing mechanism 4, a solvent dehydration bubbling mechanism 5, a drying mechanism 6, a loading table 7 and an unloading table 8, a mobile Mechanism 9 and suspension hook 10.

[0089] The cleaning object is the radar electronic components of the relevant connectors that have been assembled and welded.

[0090] The water-based environmental protection cleaning operation steps for the flux generated during the welding process of radar electronic components are as follows:

[0091] (1) Clamping the radar electronic components to be cleaned

[0092] Clamp and fix 25 radar electronic components C to be cleaned on the cleaning fixture 1, and send them to the loading table 7;

[0093] The arrangement spacing between adjacent radar electronic components to be cleaned is 8cm.

[0094] (2) soaking ultrasonic jet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com