Squeezing type dewatering machine

A dehydrator and frame technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of noise pollution, loud noise, human injury, etc., and achieve the effects of low noise pollution, easy follow-up use, and strong dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through specific examples.

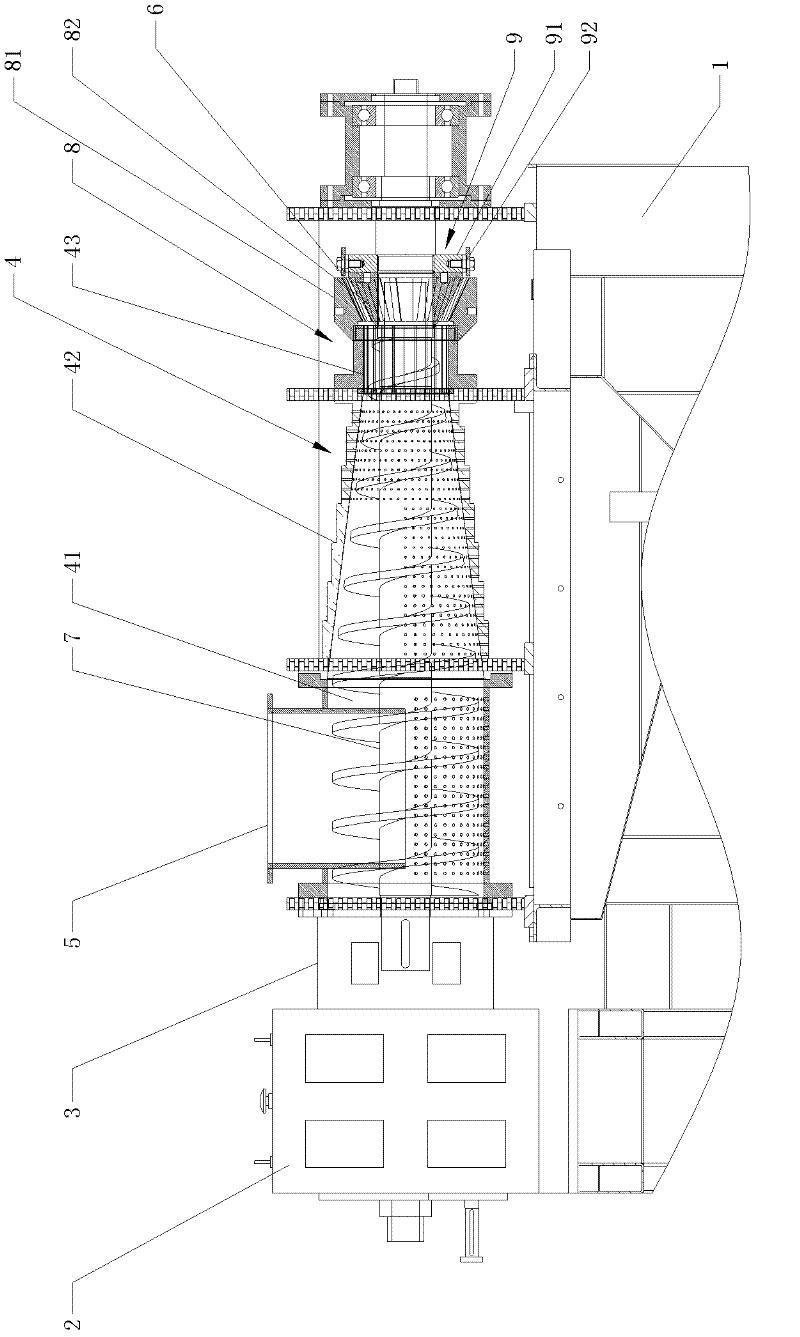

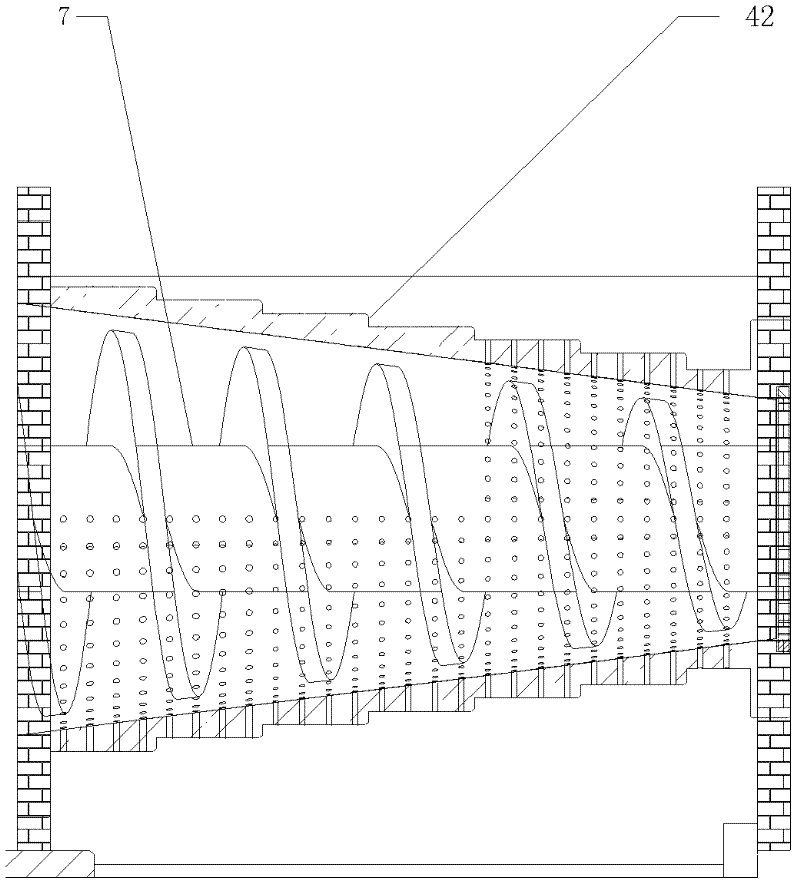

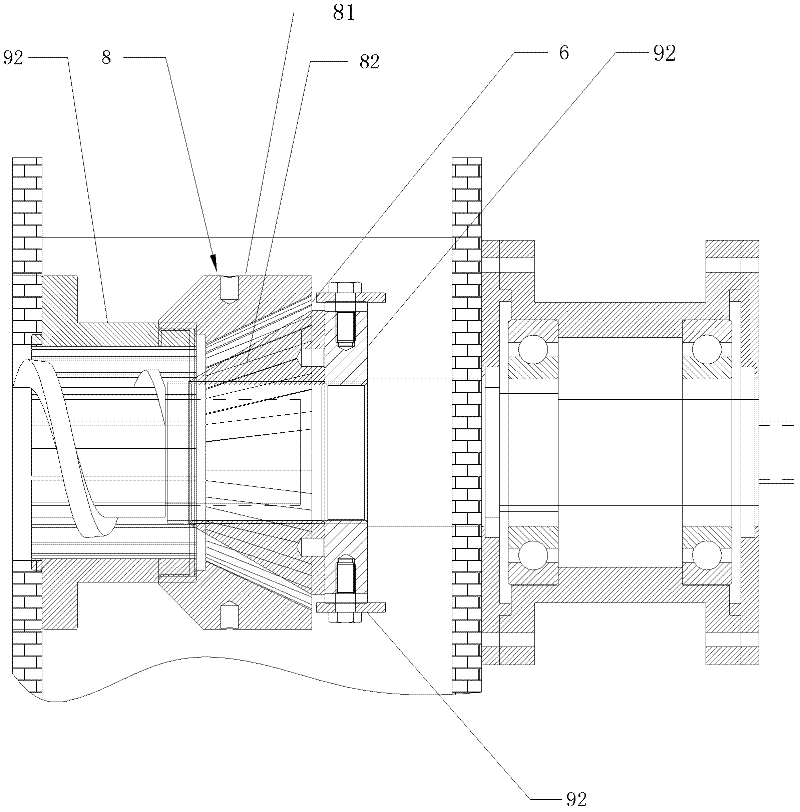

[0022] Such as figure 1 , shown in 2 and 3, the squeeze dehydrator includes a frame 1, a filter cartridge 4 with a filter hole is fixed on the frame 1, and a conical screw 7 with helical blades is installed in the filter cartridge 4, The filter cartridge 4 includes a primary filter cartridge body 41 and a secondary filter cartridge body 42 connected to each other, the primary filter cartridge body 41 is provided with a feed port 5, and the secondary filter cartridge body 42 is pushed along the direction conical contraction, the end of the secondary filter cylinder 42 is connected with a squeeze cylinder 43, the conical screw 7 runs through the primary filter cylinder 41, the secondary filter cylinder 42 and the squeeze cylinder 43, the secondary The outer peripheral wall of the filter cartridge body 42 is arranged in a stepped shape. The filter holes are arranged at the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com