Dewatering device for inner chamber of hose and operation method thereof

A dehydration device and hose technology, applied in the direction of drying solid materials, centrifuges, and drying solid materials without heating, can solve the problems of precision and complexity, long time and low efficiency of infusion sets, and achieve convenient use, low cost, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

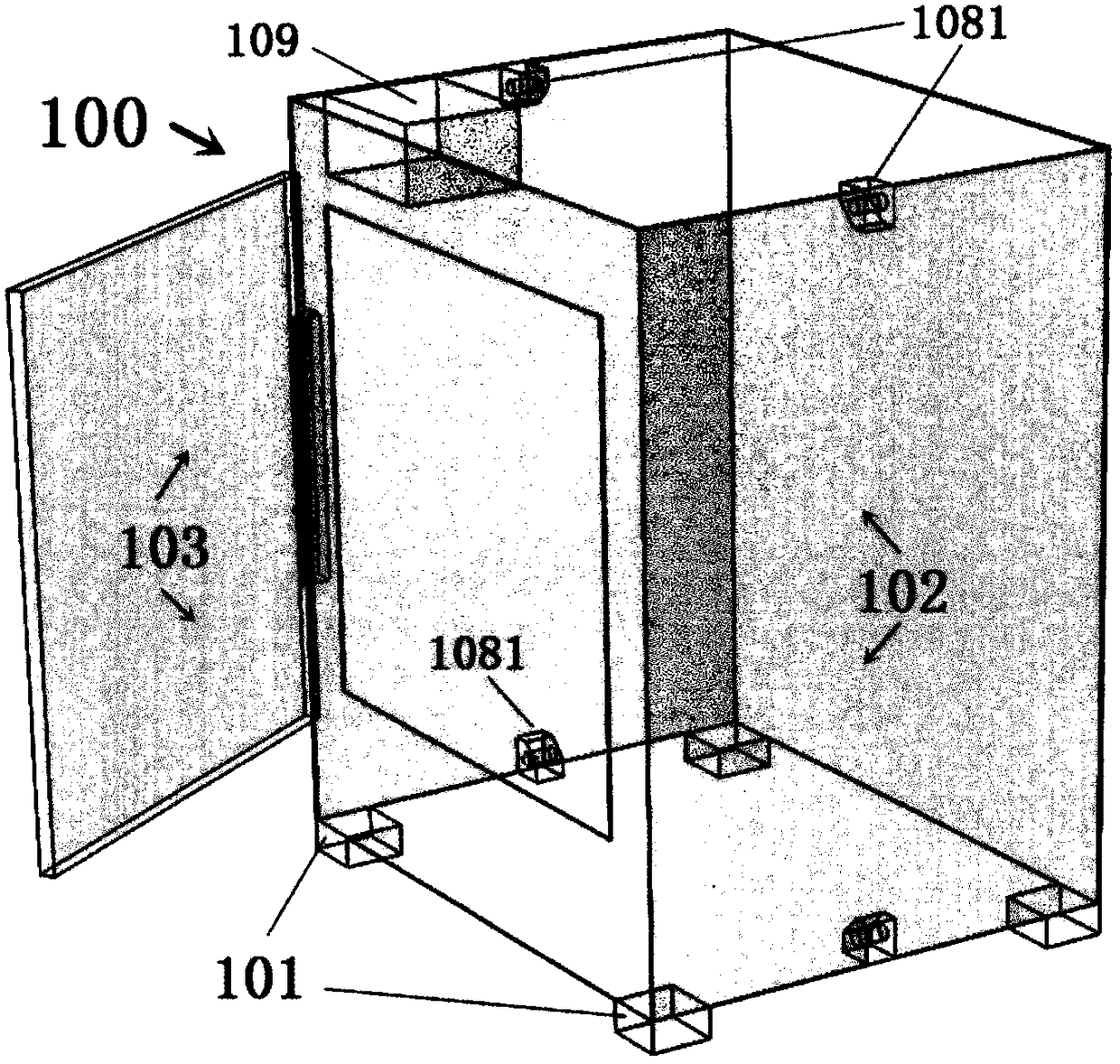

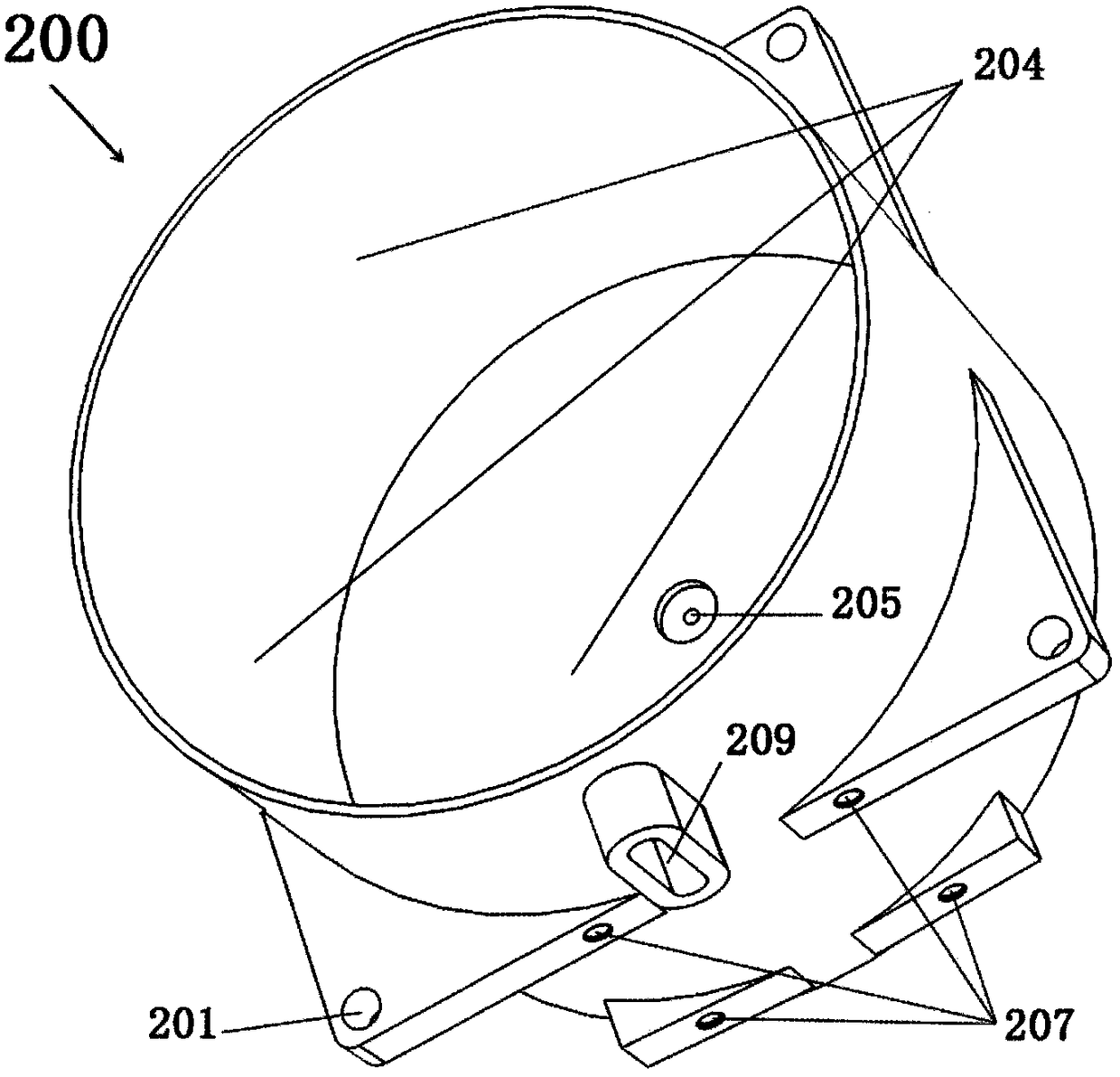

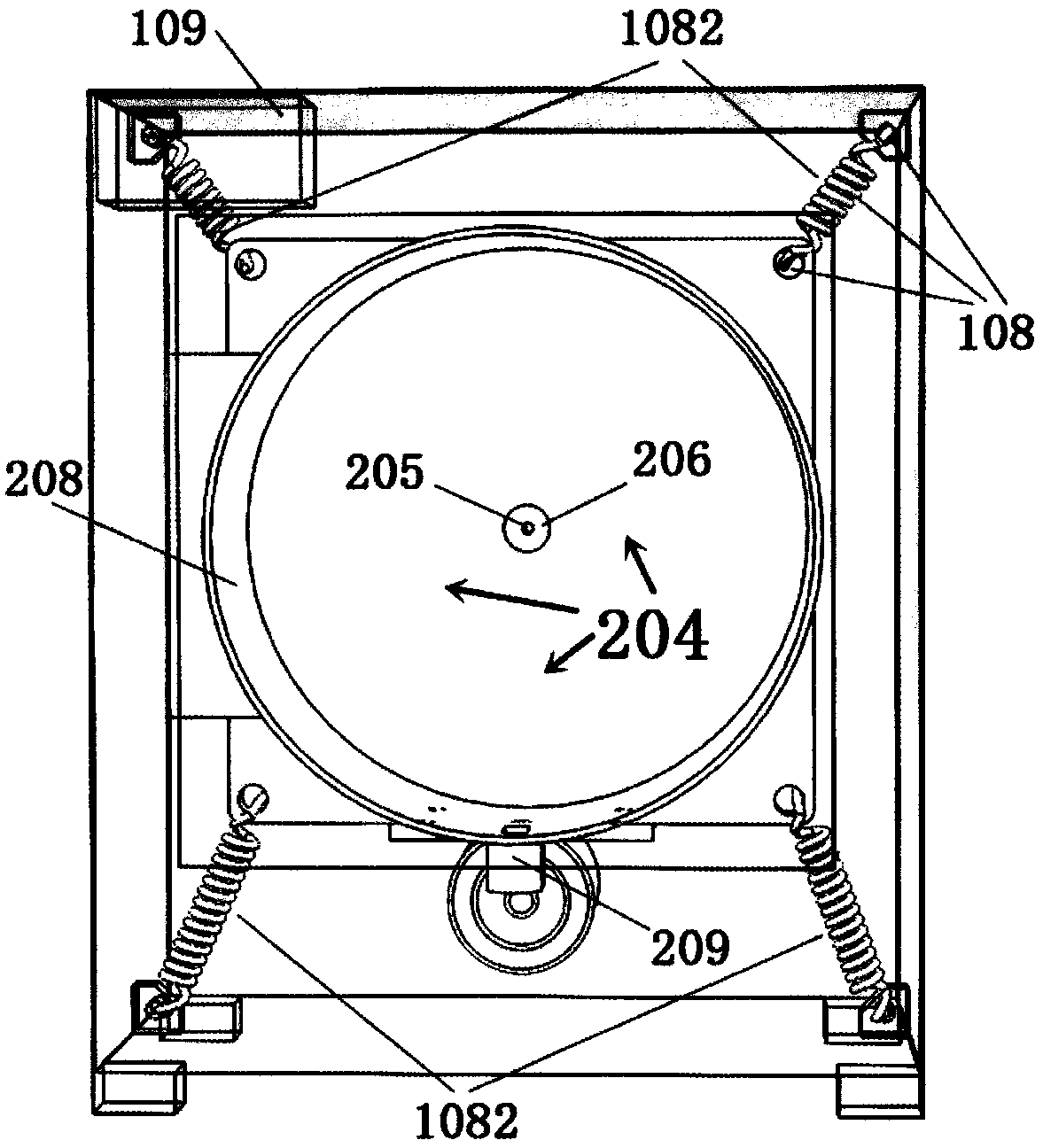

[0088] The object of the present invention is to provide a hose lumen dehydration device to solve the above problems. It is especially suitable for super-long hoses with impermeable outer walls (such as vitrectomy head tubes, tourniquets, silicone suction tubes, urinary catheters) or medical devices with small openings and large cavities (such as ear washing balls, guide needle guards, etc.) sets, respirators, nebulizers) for dehydration. Using the device of the invention instead of manpower manual operation can significantly improve labor productivity and avoid secondary pollution caused by compressed air or negative pressure suction. Especially when the lumen-shaped instruments are processed in batches with the decompression boiling washing machine, the coiled hose is taken out from the washing machine and directly put into the device of the present invention for dehydration without unfolding. The operation is extremely simple and the effect is excellent and obvious. The ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com