Electroosmosis sludge treatment device

A sludge treatment and electro-osmosis technology, applied in electrochemical sludge treatment, sludge treatment, water/sludge/sewage treatment, etc., can solve problems such as high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

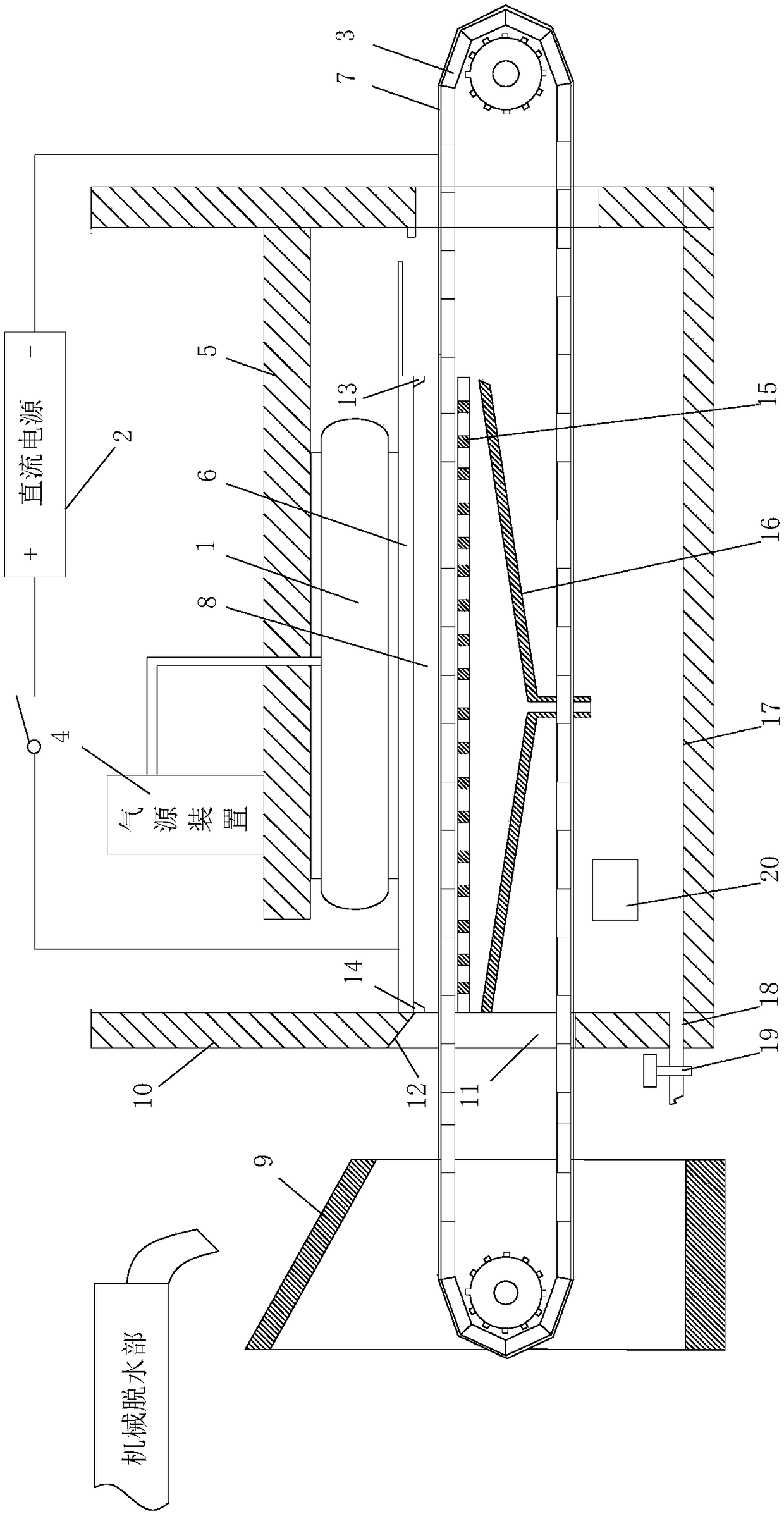

[0029] The invention provides an electroosmotic sludge treatment device, such as figure 1 and figure 2 As shown, it includes an electroosmosis dehydration part, and the electroosmosis dehydration part includes an air spring 1, a DC power supply 2, a conveyor belt 3, an air source device 4 connected to the air spring 1 for charging and deflation of the air spring 1, and for fixing The fixed portion 5 of the air spring 1, the upper end of the air spring 1 is fixedly connected to the fixed portion 5, the lower end of the air spring 1 is provided with an electrode plate 6, and the electrode plate 6 is connected to the positive stage of the DC power supply 2; The conveyor belt 3 is arranged below the electrode plate 6, and the outer surface of the conveyor belt 3 is covered with a metal filter screen 7, and the metal filter screen 7 is connected to the negative pole of the DC power supply 2 device; the electrode plate 6 is located directly below the electrode plate 6 A dewatering...

Embodiment 2

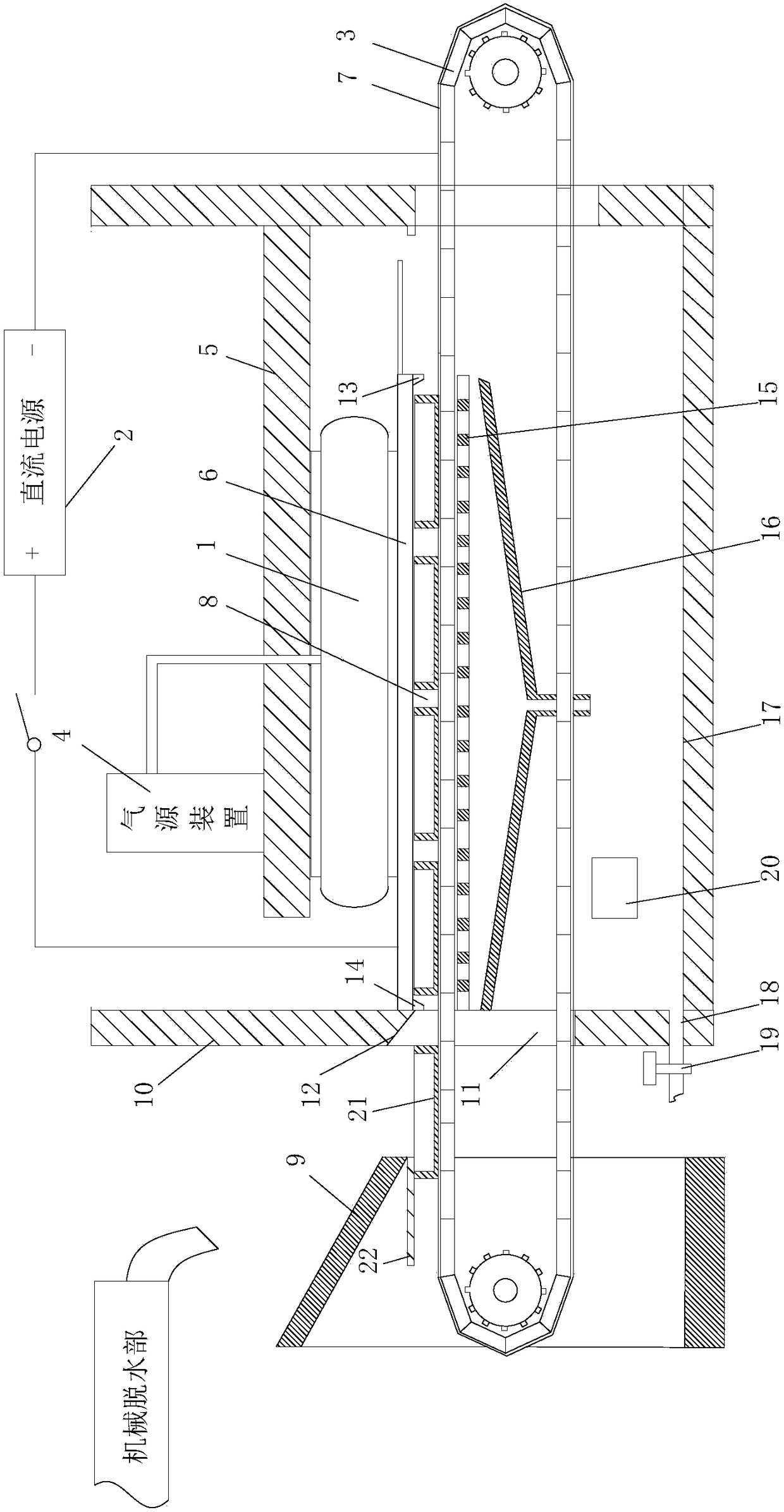

[0037] Such as figure 2 As shown, the difference from Example 1 is that the electrode plate is provided with an electromagnetic field pressurization device for pressurizing the sludge and an ultrasonic vibration device (not shown) for shaking the sludge, and the electromagnetic field pressurization Both the device and the ultrasonic vibration device can be products in the prior art; the present invention will not be described in detail.

[0038] Further, the conveyor belt is provided with a number of drawer-type mud pressing boards 21 evenly distributed along the moving direction of the conveyor belt. The bottom of the drawer-type mud pressing boards 21 is provided with a cathode electrode plate, and a mud guard is provided below the mud inlet slideway. device 22, the bottom of the mudguard device 22 is flat with the top of the drawer type mud pressing plate 21; the cathode electrode plate is connected with the negative pole of the DC power supply device. Wherein, as an opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com