Manual treadle-type rectangular mop cleaning and dehydrating barrel

A manual pedal-type, mop cleaning technology, applied in the direction of cleaning carpets, cleaning floors, cleaning equipment, etc., can solve problems such as the difficulty of electric driving of physical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

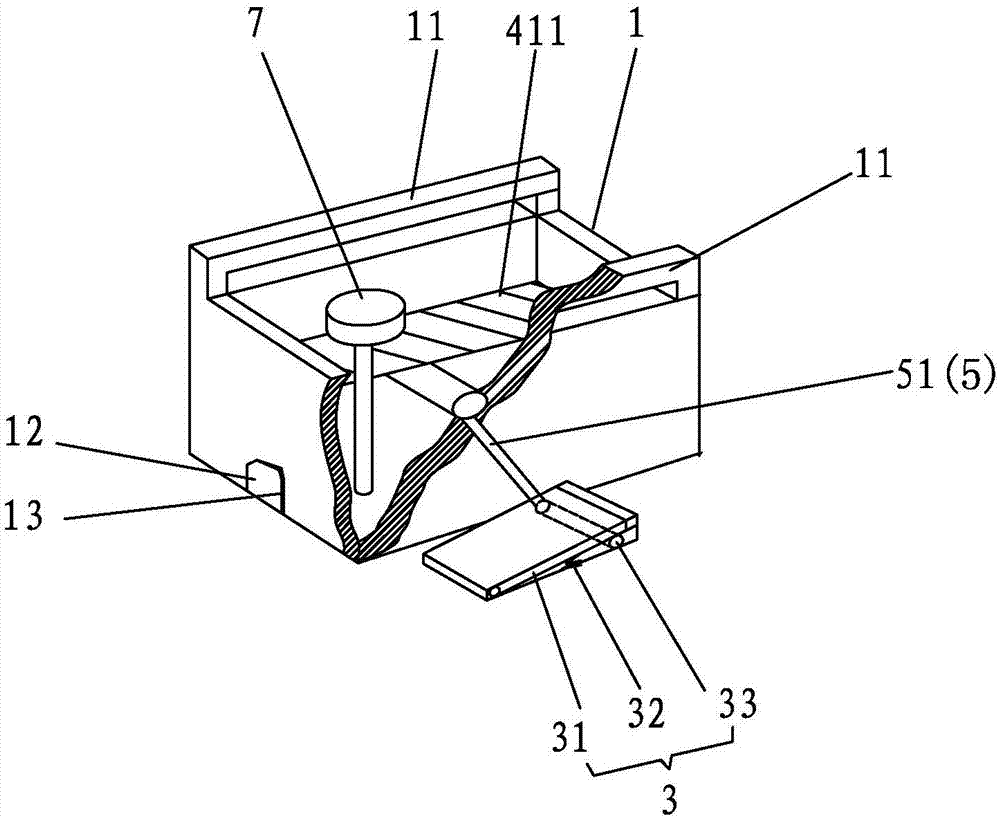

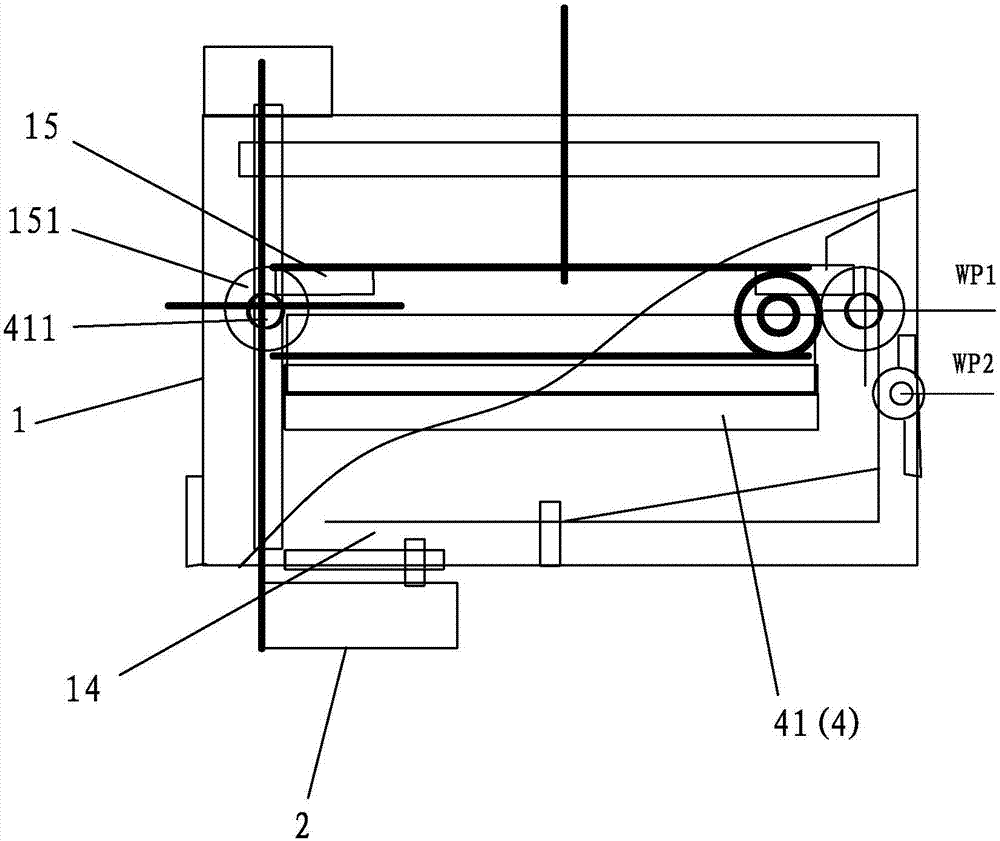

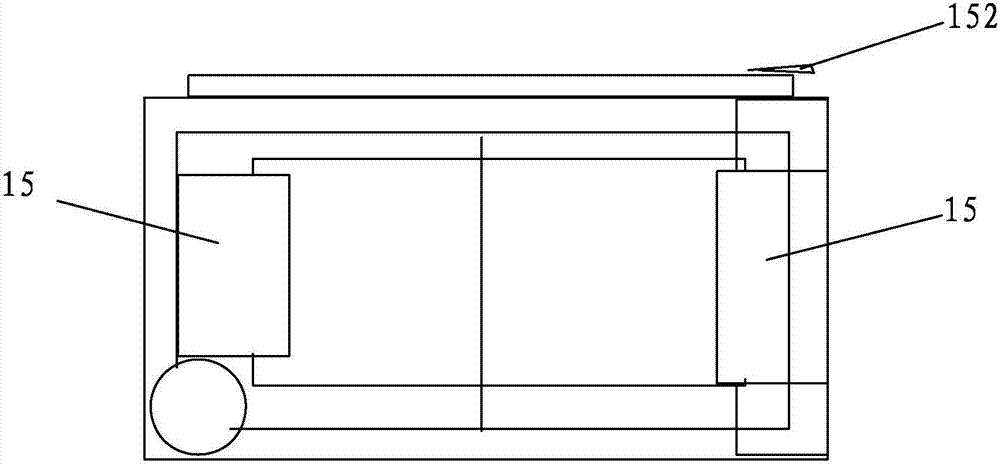

[0031] This case involves a manual foot-operated rectangular mop cleaning and dehydration cylinder, such as Figure 1-5 As shown, it mainly includes a cleaning tank 1, a storage tank 2, a pedal device 3, a rubbing plate translation mechanism 4, a connecting rod crank mechanism 5, a dehydration control assembly 6, a pump assembly 7 and a switch assembly.

[0032] The cleaning tank 1 is the main part of the cleaning and dehydrating cylinder, which has a cylindrical structure and is used to contain cleaning liquid for the mop to extend into for cleaning. The rubbing plate translation mechanism 4 is arranged in the cleaning tank 1, and the rubbing plate translation mechanism 4 has a rubbing plate 41, and the rubbing plate 41 is horizontally movable in the cleaning tank 1. The kneading plate translation mechanism 4 is connected to the pedal de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com