Method for realizing 2-picoline dehydration by side withdrawal from azeotropic distillation column

A technology of azeotropic distillation column and picoline, which is applied in the direction of sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problems of high moisture content of 2-picoline affecting recycling, etc., and achieve product High recovery rate, good separation effect and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

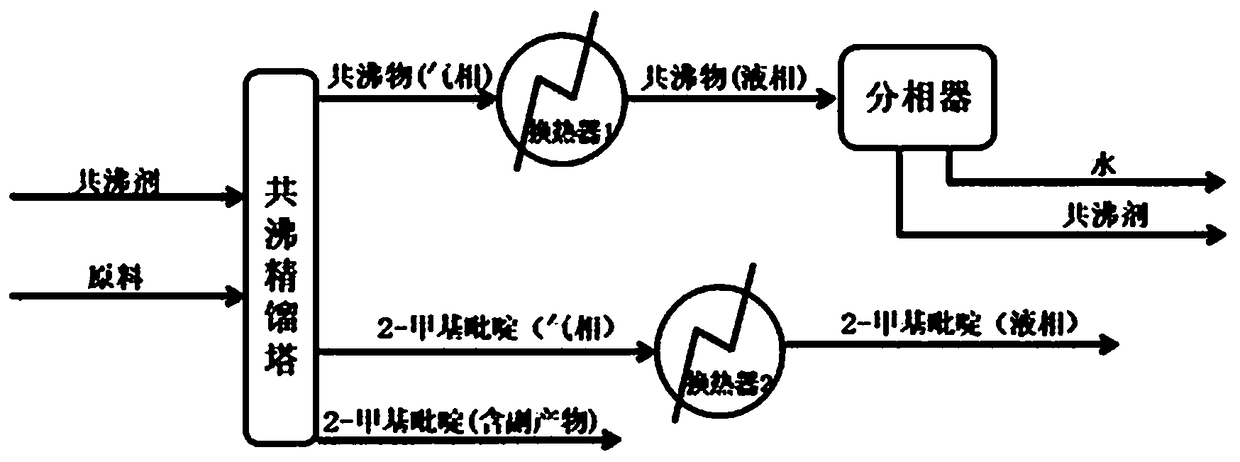

[0021] as attached figure 1 As shown, the 2-picoline / water solution with a mass fraction of 8% is continuously fed to an azeotropic distillation column containing 15 trays, the flow rate is 200kg / h, and the feeding position is the 9th tray; The entrainer cyclohexane is continuously fed to the rectification column from the first tray, the flow rate is 1472kg / h, and the amount of the entrainer is 8 times of the water quality at this time; the tower still heating device is turned on. The operating pressure of the rectification tower is 101.325kPa, the temperature at the top of the tower is 65°C, and the temperature at the bottom of the tower is 125°C.

[0022] Extraction and follow-up operations are as follows:

[0023] (1) All the gas phase at the top of the tower is taken out, then cooled to a liquid phase by heat exchanger 1, and then carried out in a phase separator for phase separation operation, and the phase separation time is 5 hours;

[0024] The gas phase at the top o...

Embodiment 2

[0029] The difference between this embodiment and embodiment one is that the 2-picoline / water solution with a mass fraction of 50% is continuously fed to an azeotropic rectification column containing 30 trays, with a flow rate of 100kg / h, The feeding position is the 11th tray; the entrainer cyclohexane is continuously fed to the rectification column from the first tray, the flow rate is 300kg / h, and the amount of the entrainer is 6 times the water quality ; Turn on the tower kettle heating device. The operating pressure of the rectification tower is 101.325kPa, the temperature at the top of the tower is 55°C, and the temperature at the bottom of the tower is 128°C.

[0030] Extraction and follow-up operations are as follows:

[0031] (1) All the gas phase at the top of the tower is taken out, then cooled to a liquid phase by heat exchanger 1, and then carried out in a phase separator for phase separation operation, and the phase separation time is 3 hours;

[0032] The gas p...

Embodiment 3

[0037] The difference between this embodiment and embodiment two is that the 2-picoline / water solution with a mass fraction of 99% is continuously fed to an azeotropic rectification column containing 10 trays, and the flow rate is 100kg / h. The feeding position is the fifth tray; the entrainer cyclohexane is continuously fed from the first tray to the rectification column at a flow rate of 10kg / h, and the amount of the entrainer is 10 times the water mass ; Turn on the tower kettle heating device. The operating pressure of the rectification tower is 101.325kPa, the temperature at the top of the tower is 62°C, and the temperature at the bottom of the tower is 130°C.

[0038] Extraction and follow-up operations are as follows:

[0039] (1) The gas phase at the top of the tower is all extracted, and then cooled to a liquid phase by heat exchanger 1, and then carried out in a phase separator for phase separation operation, and the phase separation time is 0.5h;

[0040] The gas pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com