Sludge curing agent and production method thereof

A production method and curing agent technology, applied in chemical instruments and methods, fixed/solidified sludge treatment, sludge treatment, etc., can solve problems such as poor economical practicability, poor repair effect, high technical difficulty, etc., and achieve high frost resistance performance, short setting time, and high impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

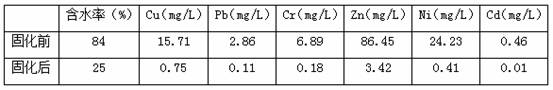

Embodiment 1

[0026] A sludge solidifying agent, made of the following raw materials in parts by weight: 60 parts of sulphoaluminate cement, 40 parts of Portland cement, 40 parts of ultrafine slag powder, 40 parts of fly ash, 10 parts of dispersible latex powder, 10 parts of sodium silicate, 4 parts of calcium hydroxyphosphate, 12 parts of modified nano-montmorillonite.

[0027] The particle size of the ultrafine slag powder is less than 30 μm.

[0028] The redispersible latex powder is acrylic rubber powder or vinyl acetate-ethylene copolymer powder.

[0029] The production method of the modified nano-montmorillonite is as follows: heating the montmorillonite at 150° C. for 5.5 hours, and then grinding and pulverizing to prepare the nano-montmorillonite.

[0030] The production method of described sludge curing agent comprises the steps:

[0031] (1) Grind sulfoaluminate cement, Portland cement, fly ash, sodium silicate, and calcium hydroxyphosphate, and pass through a 200-mesh sieve;

...

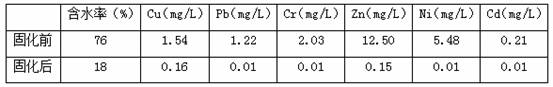

Embodiment 2

[0034] A sludge curing agent, made of the following raw materials in parts by weight: 80 parts of sulphoaluminate cement, 25 parts of Portland cement, 55 parts of ultrafine slag powder, 30 parts of fly ash, 6 parts of dispersible latex powder, 6 parts of sodium silicate, 8 parts of calcium hydroxyphosphate, and 8 parts of modified nano-montmorillonite.

[0035] The particle size of the ultrafine slag powder is less than 30 μm.

[0036] The redispersible latex powder is acrylic rubber powder or vinyl acetate-ethylene copolymer powder.

[0037] The production method of the modified nano-montmorillonite is as follows: heating the montmorillonite at 160° C. for 5 hours, and then grinding and pulverizing the nano-montmorillonite to produce the nano-montmorillonite.

[0038] The production method of described sludge curing agent comprises the steps:

[0039] (1) Grind sulfoaluminate cement, Portland cement, fly ash, sodium silicate, and calcium hydroxyphosphate, and pass through a...

Embodiment 3

[0042] A sludge solidifying agent, made of the following raw materials in parts by weight: 100 parts of sulphoaluminate cement, 10 parts of Portland cement, 70 parts of ultrafine slag powder, 20 parts of fly ash, 2 parts of dispersible latex powder, 2 parts of sodium silicate, 12 parts of calcium hydroxyphosphate, and 12 parts of modified nano-montmorillonite.

[0043] The particle size of the ultrafine slag powder is less than 30 μm.

[0044] The redispersible latex powder is acrylic rubber powder or vinyl acetate-ethylene copolymer powder.

[0045] The production method of the modified nano-montmorillonite is as follows: heating the montmorillonite at 170° C. for 5.5 hours, and then grinding and pulverizing to prepare the nano-montmorillonite.

[0046] The production method of described sludge curing agent comprises the steps:

[0047] (1) Grind sulfoaluminate cement, Portland cement, fly ash, sodium silicate, and calcium hydroxyphosphate, and pass through a 300-mesh sieve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com