Multifunctional wet tissue and preparation method

A multi-functional wet wipe technology, applied in the field of multi-functional wet wipes and its preparation, can solve problems such as adverse effects of sensitive people, chemical residues, harmful to human health, etc., to achieve environmental protection, low production costs, reduce The effect of breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A method for preparing a multifunctional wet wipe comprises the following steps:

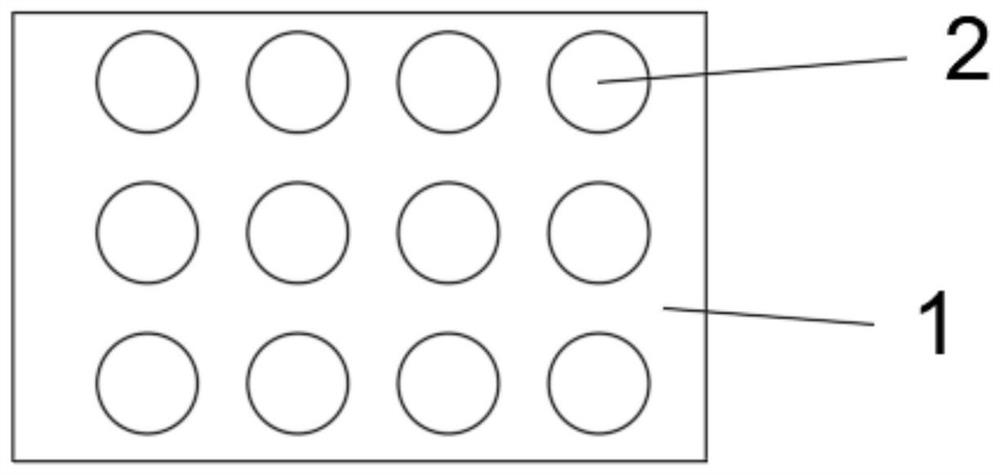

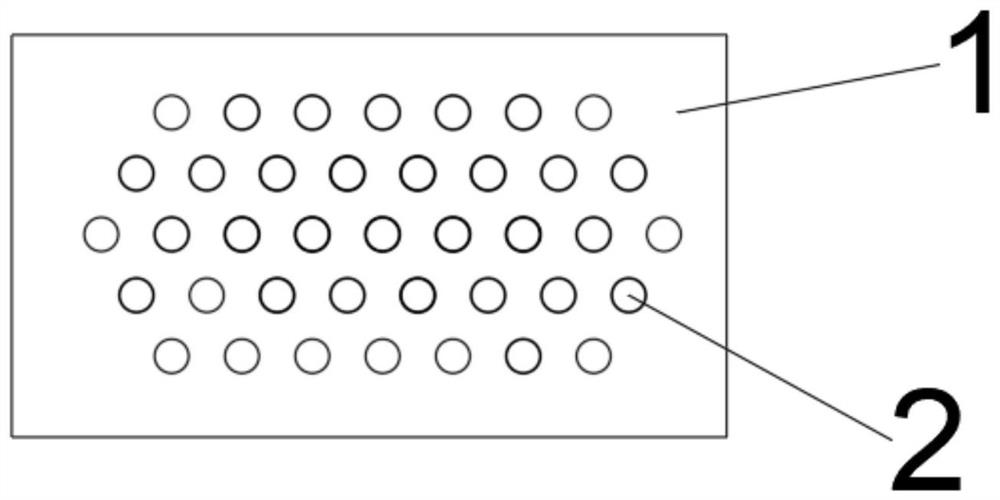

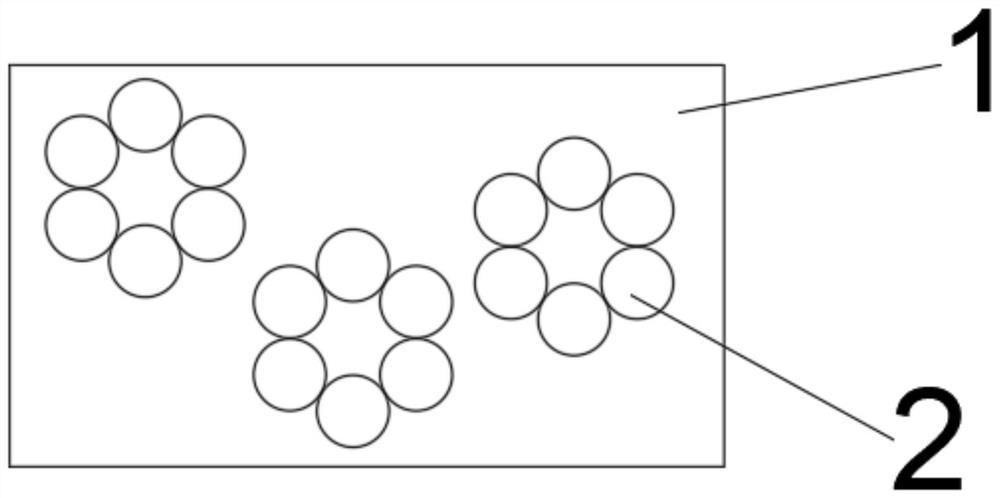

[0038] S0. Use matching cutters to punch the base material of the wet wipes in an array. The array can be a circular array or a rectangular array. In order to meet personalized customization, arrayed through holes such as cartoon images can also be made. The aperture is 0.1-2mm , the pores occupy no more than 50% of the area of the wet wipe body, and the setting of the aperture depends on the breaking force of the wet wipe body after molding, the foaming and washing effect of the wet wipe after washing, and the degree of degradation in the natural environment in the later stage.

[0039] S1, preparing the base material of the wet wipe and soaking it into a wet wipe body;

[0040] Preferably, the mass ratio is 2-3 parts of cotton fiber, 3-5 parts of soybean fiber, and 1-2 parts of coconut fiber to make a surface density of 0.08-1.2kg / m 2 The wet tissue base material is put into the wet ...

Embodiment 1

[0049]Example 1. Mix the mass ratio of 3 parts of cotton fiber, 3 parts of soybean fiber and 1 part of coconut fiber to make a wet tissue base material with an area density of 0.08kg / m2, and put the wet tissue base material into the wet tissue liquid , the soaking time is 100 minutes, the soaking temperature is kept at 90° C., and the mass ratio of the wet wipe substrate to the wet wipe liquid is 1:1.

[0050] Put 10 parts of deionized water with a temperature of 40-60 ℃ into the liquid mixing tank, then add 1 part of KAC, turn on the agitator and stir evenly, then turn off the agitator, put in 2 parts of AOS, and stand still for more than 1 hour to completely defoam , Dispense the detergent into the aluminum foil outer packaging.

[0051] Put the wet wipes on the conveyor belt. Fiber optic sensor probes are installed on both sides of the conveyor belt. The washing bag delivery mechanism is pre-installed above the conveyor belt. The delivery mechanism is connected with the fib...

Embodiment 2

[0053] Embodiment 2, the mass ratio is 2 parts of cotton fiber, 5 parts of soybean fiber, and 1 part of coconut fiber is mixed and made into a wet tissue base material whose surface density is 1.2kg / m2, such as figure 1 As shown, the wet tissue substrate is perforated in a rectangular array, the hole diameter is 0.1 mm, and the area of the holes on a single wet tissue substrate is controlled to account for less than 50%. Put the wet wipe base material into the wet wipe liquid, the soaking time is 50 minutes, the soaking temperature is kept at 60°C, and the mass ratio of the wet wipe base material to the wet wipe liquid is 5:1.

[0054] Put 10 parts of deionized water at a temperature of 40-60°C into the liquid mixing tank, then add 1 part of KAC, turn on the mixer and stir evenly, then turn off the mixer, put 1 part of AOS, and let it stand for more than 1 hour to completely defoam , Dispense the detergent into the plastic outer packaging.

[0055] Put the wet wipes on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com