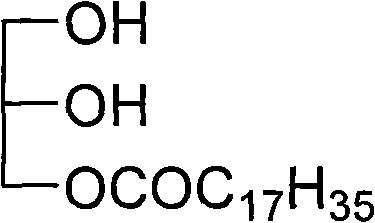

Quick preparation method of glycerin monostearate

A technology of glyceryl monostearate and stearic acid, which is applied in the field of chemical additives, can solve the problems of extremely high technical requirements, high product cost, cumbersome preparation process, etc., and achieve superior compounding performance and strong compounding performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

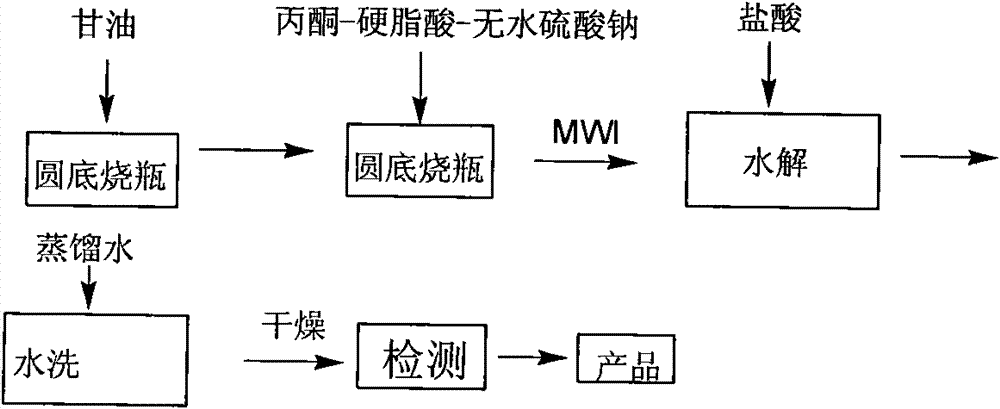

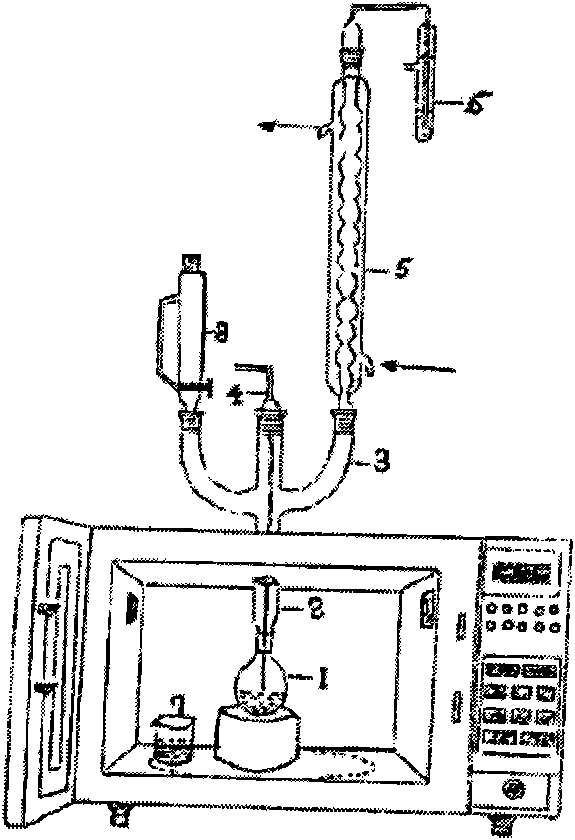

Method used

Image

Examples

Embodiment 1

[0025] Put metered 11mmol glycerin, 20mmol acetone, 9mmol stearic acid, 0.5mmol copper p-toluenesulfonate, and 2mmol anhydrous sodium sulfate into a 50ml round bottom flask successively; place the flask in a microwave radiation heating device, set Set the microwave radiation power to 300W, time 4min, start the reaction, after the reaction, cool to room temperature, stand still, hydrolyze to neutral with 2mol / L hydrochloric acid, wash with distilled water three times (10ml each time). dry. The product conversion rate is 92%. The product has a melting point of 62-63°C.

Embodiment 2

[0027] 10.5mmol glycerol, 20mmol acetone, 9mmol stearic acid, 0.5mmol copper p-toluenesulfonate, and 2mmol anhydrous sodium sulfate after metering were dropped into a 50ml round-bottomed flask in turn; the flask was placed in a microwave radiation heating device, Set the microwave radiation power to 300W, time 4min, start the reaction, after the reaction, cool to room temperature, stand still, hydrolyze to neutral with 2mol / L hydrochloric acid, wash with distilled water three times (10ml each time). dry. The product conversion rate is 89%. The product has a melting point of 62-63°C.

Embodiment 3

[0029] Put metered 12mmol glycerin, 20mmol acetone, 9mmol stearic acid, 0.5mmol copper p-toluenesulfonate, and 2mmol anhydrous sodium sulfate into a 50ml round bottom flask successively; place the flask in a microwave radiation heating device, set Set the microwave radiation power to 300W, time 4min, start the reaction, after the reaction, cool to room temperature, stand still, hydrolyze to neutral with 2mol / L hydrochloric acid, wash with distilled water three times (10ml each time). dry. The product conversion rate is 91%. The product has a melting point of 62-63°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com