Binary nitrogen-containing polymer diesel pour point depressant, and preparation method and application thereof

A diesel pour point depressant, polymer technology, applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of poor pour point depressant effect, single composition, etc., to improve low-temperature flow performance, reduce freezing point and Cold filter point and pour point depressing effect are obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

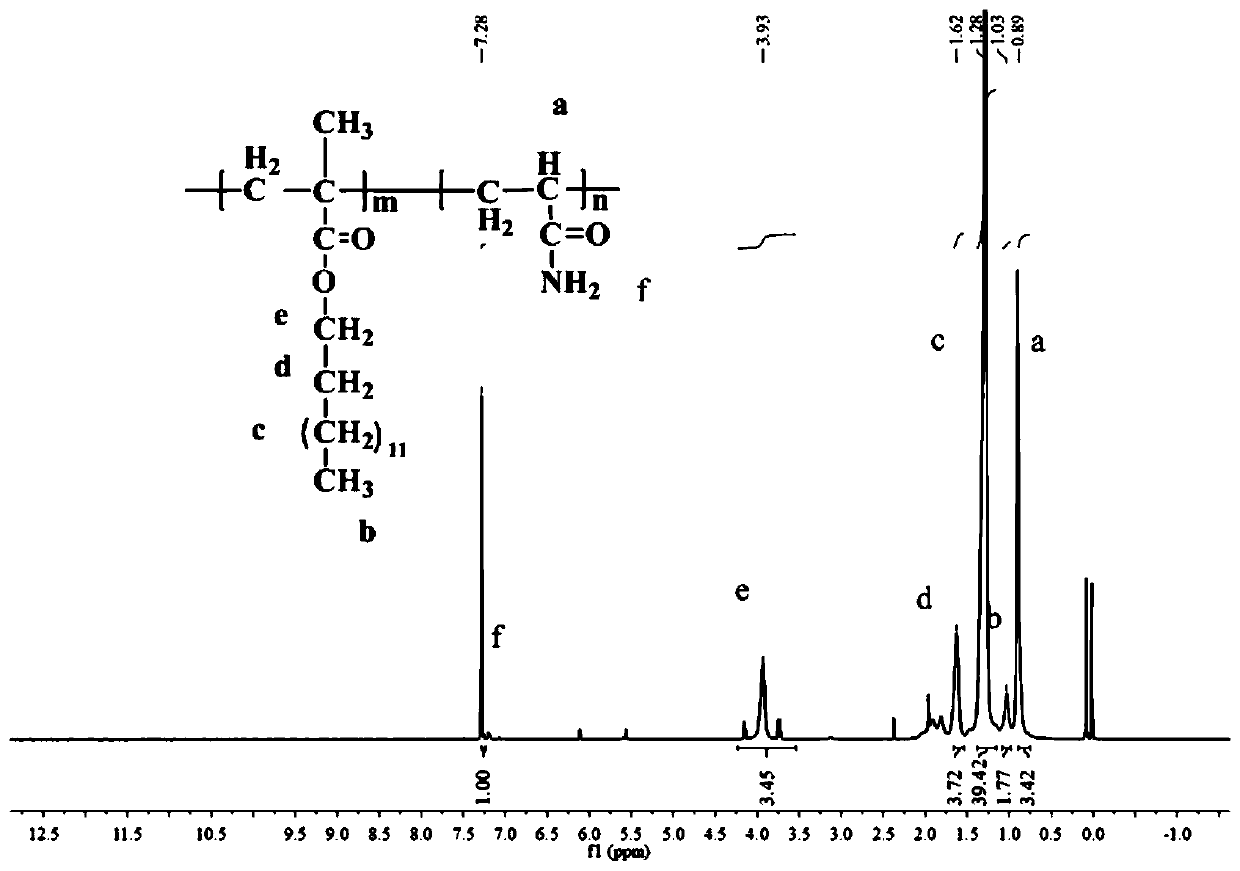

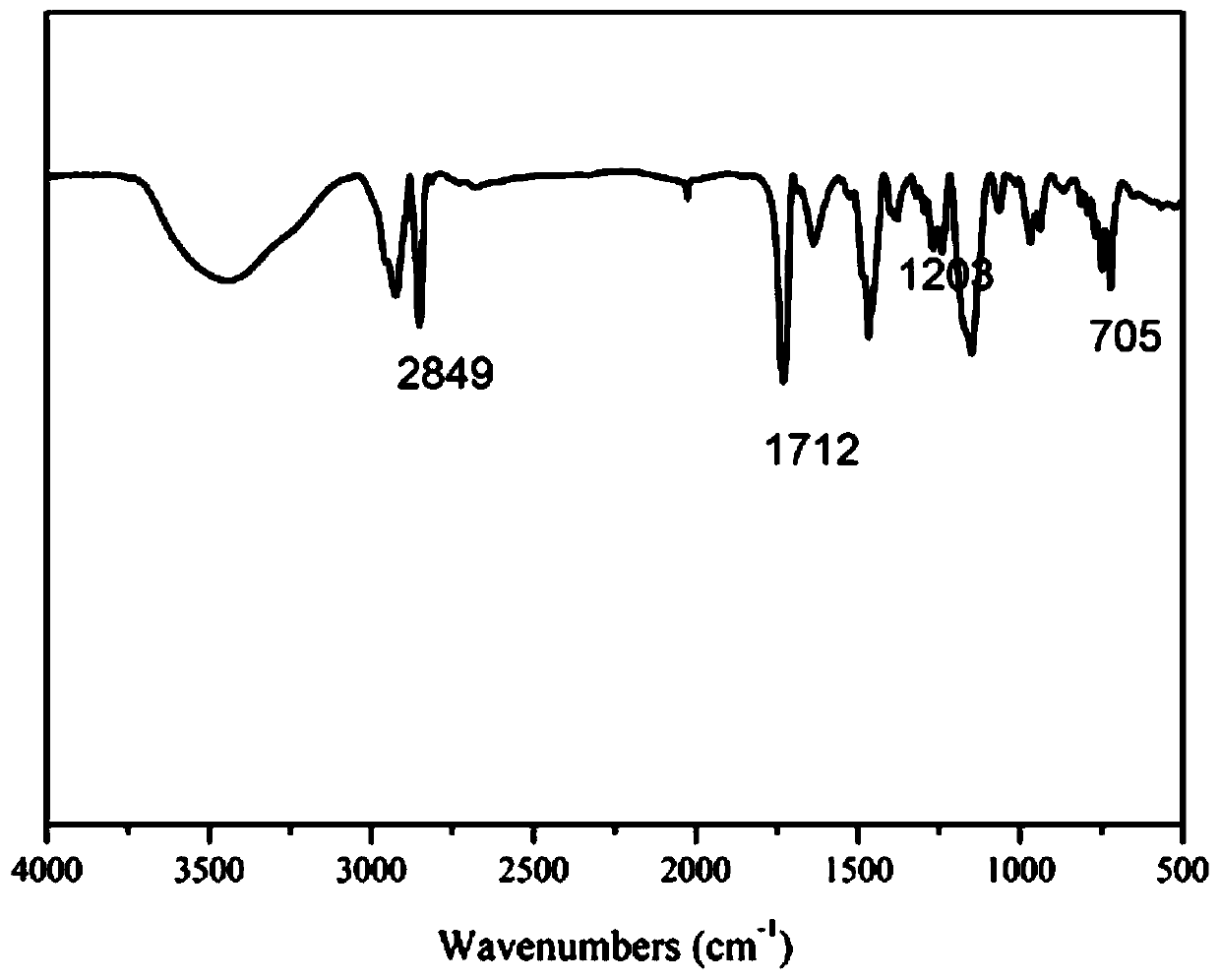

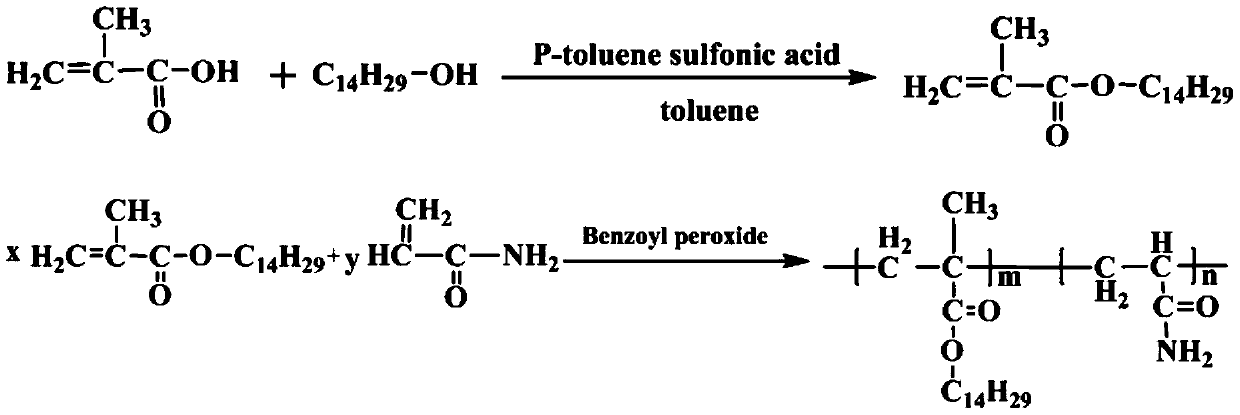

Method used

Image

Examples

Embodiment 1

[0028] (1) Add 10.33g (0.12mol) of methacrylic acid, 21.44g (0.1mol) of tetradecyl alcohol, and 0.192g of hydroquinone to a three-necked flask equipped with a condenser, a water separator, a thermometer, and a magnetic stirring device , 50ml toluene, heat up to 60°C to completely dissolve myristyl alcohol in toluene, then quickly add 0.254g catalyst p-toluenesulfonic acid into the three-necked flask, heat up to 110-120°C and react for 5 hours, when observed When the amount of water in the water separator is equivalent to the theoretical value, the system is in a light yellow transparent liquid state, and the reaction is terminated. After the reaction was completed, the obtained reaction solution was distilled under reduced pressure, and then alkali washing and water washing were carried out after removing the solvent. The alkali washing was washed with a 5% NaOH solution to remove p-toluenesulfonic acid and unreacted methyl alcohol. Acrylic acid generally needs to be washed 3-...

Embodiment 2

[0032] The difference from Example 1 is that the 8g tetradecyl methacrylate-acrylamide binary polymer and 2g EVA added in step (3) are replaced by adding 4g tetradecyl methacrylate-acrylamide binary polymer , 2g EVA, all the other are with embodiment 1.

Embodiment 3

[0034] The difference from Example 1 is that the 8g tetradecyl methacrylate-acrylamide binary polymer and 2g EVA added in the step (3) are replaced by adding 2g tetradecyl methacrylate-acrylamide binary polymer , 2g EVA, all the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com