Compound microorganism oil-displacing agent for oil production and compounding method thereof

A technology of composite microorganisms and oil displacement agents, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of large formation damage, high microbial inactivation rate, and large environmental pollution in the reservoir, and achieve composite The effect of strong performance, wide application range and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

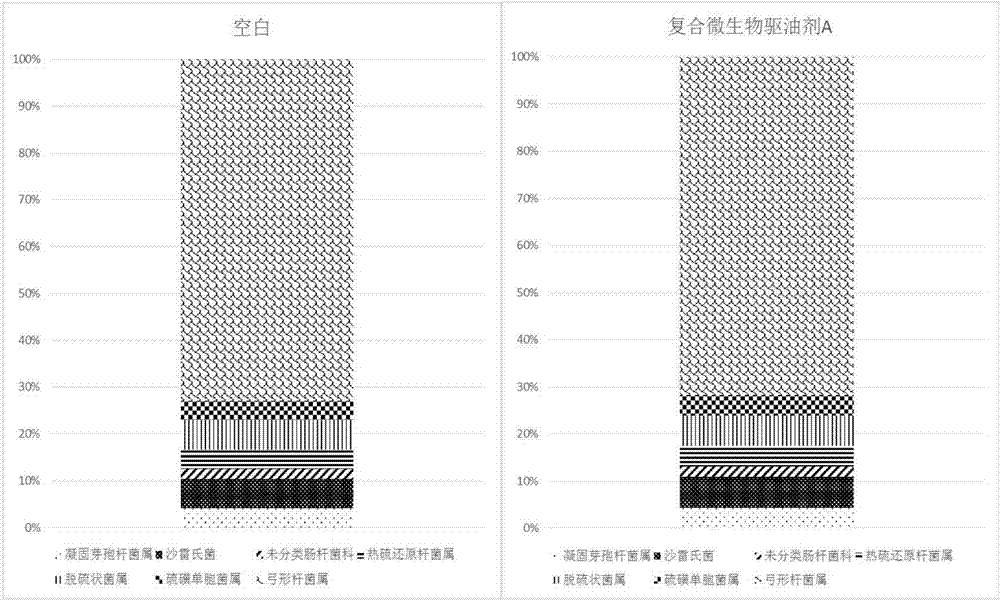

[0034] Embodiment 1 Composite microbial oil displacement agent A and its composite method for oil recovery

[0035] (1) Composite microbial oil displacement agent A component and its ratio

[0036] Composite microbial oil displacement agent A component and its proportion are as follows:

[0037]

[0038] The molecular weight of the alkyl polyoxyethylene ether polymer is 6000-8000.

[0039] After laboratory evaluation, the critical micelle concentration of compound microbial oil displacement agent A is 9.5 mg / L; when the mass concentration of alkyl polyoxyethylene ether polymer is greater than 0.05%, the oil washing efficiency of A is greater than 96.0%, and the interfacial tension is lower than 0.06mN / m, see Table 1; A suitable reservoir conditions are temperature 25 ℃ ~ 71 ℃, salinity less than 72000mg / L; indoor physical simulation experiment compound microbial oil displacement agent A injection volume 0.5PV, enhanced oil recovery The rate is greater than 16%, see Table ...

Embodiment 2

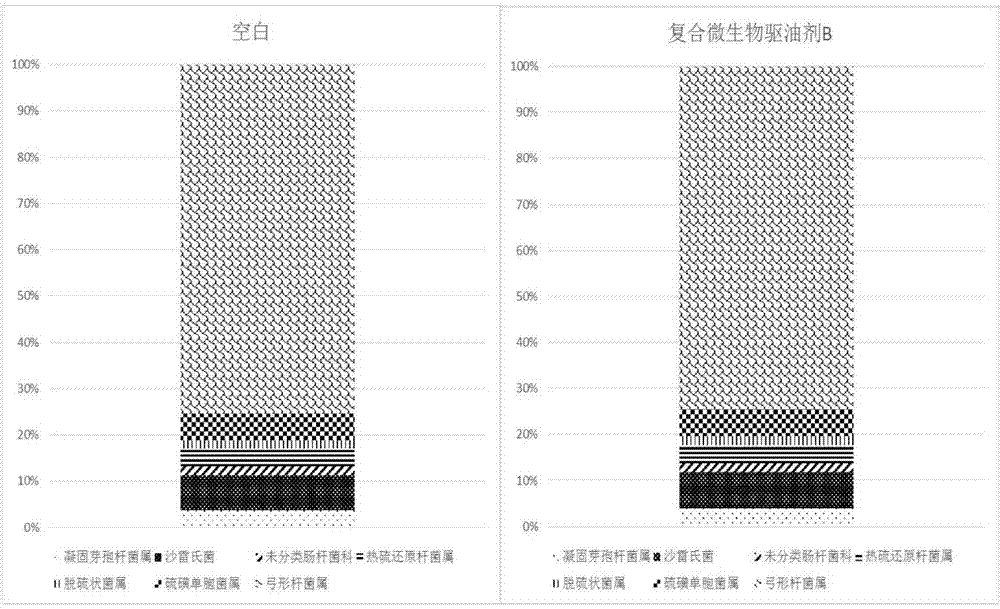

[0050] Embodiment 2 Composite microbial oil displacement agent B for oil recovery and its composite method

[0051] (1) Composite microbial oil displacement agent B component and its proportion

[0052] Composite microbial oil displacement agent B component and its proportion are as follows:

[0053]

[0054] The molecular weight of the alkyl polyoxyethylene ether polymer is 7000-8500.

[0055] After laboratory evaluation, the critical micelle concentration of compound microbial oil displacement agent B is 9.2 mg / L; when the mass concentration of alkyl polyoxyethylene ether polymer is greater than 0.05%, the oil washing efficiency of B is greater than 97.0%, and the interfacial tension is lower than 0.05mN / m, see Table 3; B is suitable for reservoir conditions with a temperature of 40°C to 85°C and a salinity of less than 70,000mg / L; the injection volume of composite microbial oil displacement agent B is 0.5PV in indoor physical simulation experiments to improve oil recove...

Embodiment 3

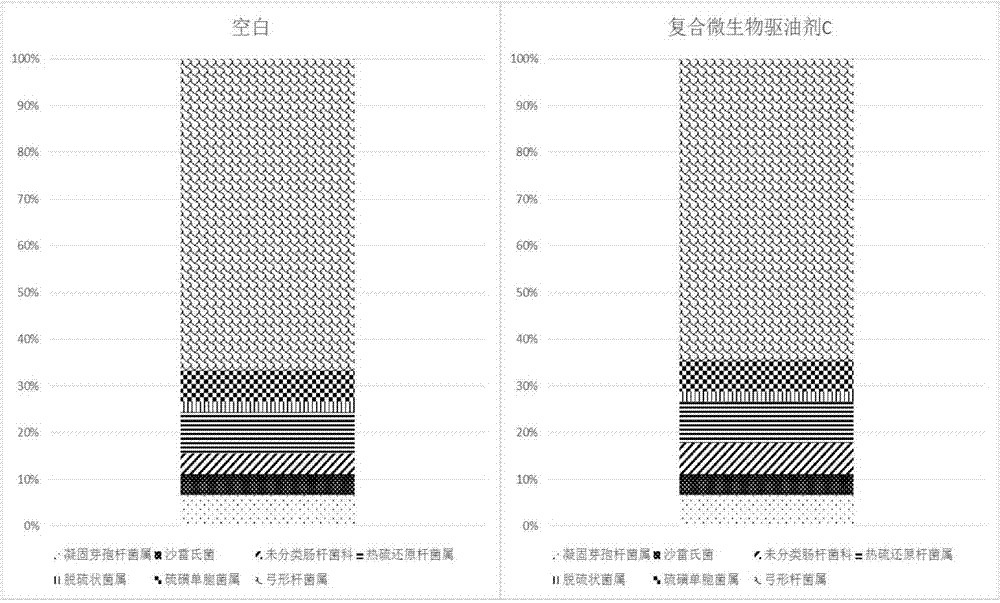

[0065] Embodiment 3 Composite microbial oil displacement agent C and its composite method for oil recovery

[0066] (1) Composite microbial oil displacement agent C component and its ratio

[0067] Composite microbial oil displacement agent C component and its ratio are as follows: 0

[0068]

[0069] The molecular weight of the alkyl polyoxyethylene ether polymer is 9000-10000.

[0070] After laboratory evaluation, the critical micelle concentration of compound microbial oil displacement agent C is 9.0mg / L; when the mass concentration of alkyl polyoxyethylene ether polymer is greater than 0.05%, the oil washing efficiency of C is greater than 98.0%, and the interfacial tension is lower than 0.06mN / m, as shown in Table 5; C is suitable for reservoir conditions with a temperature of 40°C to 75°C and a salinity of less than 65,000mg / L; the injection volume of compound microbial oil displacement agent C is 0.5PV in indoor physical simulation experiments, and the oil recovery ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com