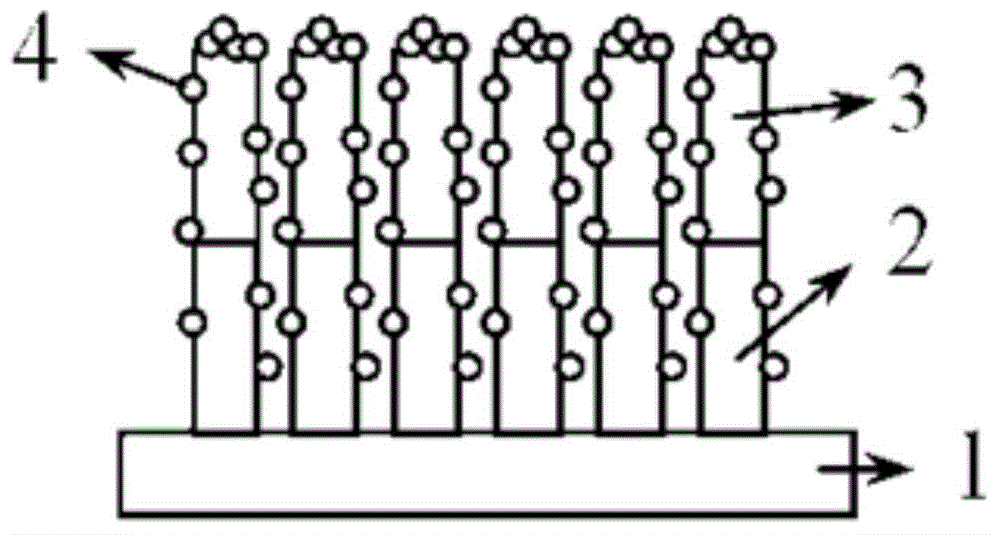

Preparation method of Si-ITO composite nanowire ordered array

A nanowire array and ordered array technology is applied in the field of preparation of Si-ITO composite nanowire ordered arrays, and achieves the effects of stable performance, uniform diameter and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of a Si-ITO composite nanowire ordered array of the present invention comprises the following steps:

[0033] The first step: the cleaning process of the nanowire substrate.

[0034] 1.1), put the nanowire substrate 1 (single crystal silicon wafer) into chloroform for ultrasonic cleaning for 10 minutes to remove the organic residue on the silicon surface;

[0035] 1.2), put the nanowire substrate 1 into deionized water and ultrasonicate for about 5 minutes, remove the residual chloroform, and then dry it with nitrogen;

[0036] 1.3), put the nanowire substrate 1 into the hydrofluoric acid (HF) with a concentration of 10% for 30s, and remove the oxidized silicon dioxide on the surface of the nanowire substrate 1;

[0037] 1.4) Put the nanowire substrate 1 into deionized water for ultrasonic cleaning for 5 minutes to remove residual HF, and then dry it with nitrogen.

[0038] The second step: the preparation of Si nanowires.

[0039] The Si nanowir...

Embodiment 1

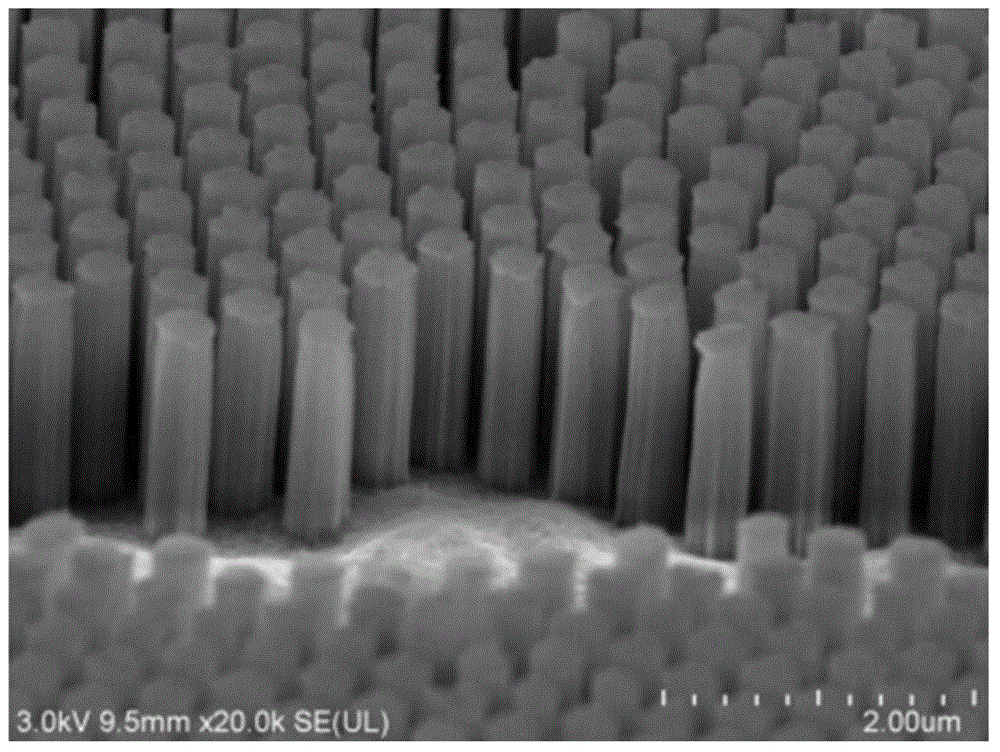

[0050] On the surface of the cleaned single crystal p-type (100) Si wafer, a single layer of PS spheres with a diameter of 670 nm was self-assembled, and the PS spheres were etched with oxygen by an inductively coupled plasma (ICP) etching machine for 200 s. The diameter of the PS pellets became -500 nm, followed by vapor deposition of metallic silver. Set the evaporation current to 115A and the evaporation rate to be The evaporation chamber pressure is 7×10 -4 Pa, the thickness of the vapor-deposited silver film is 40nm, then the silicon wafer is placed in chloroform solution, soaked for 15 minutes under ultrasonic conditions to remove PS pellets, and then the sample silicon wafer is placed in deionized water for ultrasonic cleaning for 5 minutes , to remove the residual chloroform solution, and dry naturally under nitrogen atmosphere. At this time, a silver mesh film has been formed on the surface of the sample silicon wafer.

[0051] Configure an etching solution of hyd...

Embodiment 2

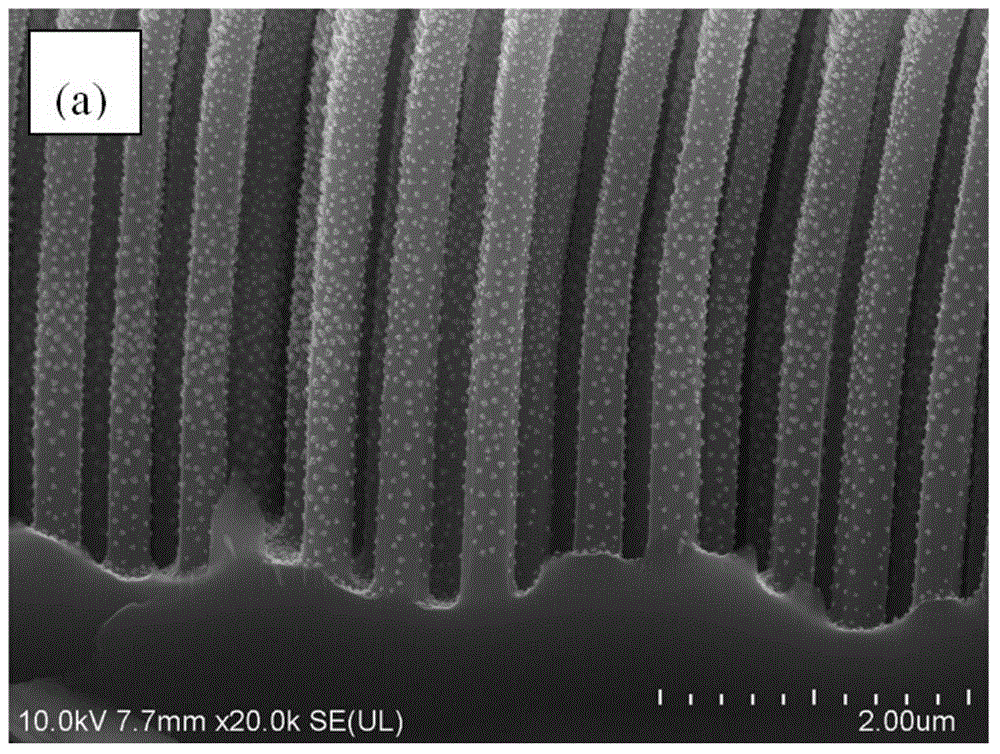

[0054] After self-assembly of PS beads with a monolayer diameter of 500 nm on the surface of the cleaned Si wafer, the PS beads were etched with oxygen for 150 s using an inductively coupled plasma (ICP) etcher, and the diameter of the PS beads became ~ 350 nm, followed by vapor deposition of metallic silver. Set the evaporation current to 115A and the evaporation rate to be The evaporation chamber pressure is 7×10 -4 Pa, the thickness of the vapor-deposited silver film is 35nm, then the silicon wafer is placed in chloroform solution, soaked for 15 minutes under ultrasonic conditions to remove PS pellets, and then the sample silicon wafer is placed in deionized water for ultrasonic cleaning for 5 minutes , to remove the residual chloroform solution, and dry naturally under nitrogen atmosphere. At this time, a silver mesh film has been formed on the surface of the sample silicon wafer.

[0055] Configure an etching solution of hydrofluoric acid (HF): hydrogen peroxide (H2O2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com