A cogeneration system of waste heat, electricity and water

A technology of electricity, water and waste heat, applied in general water supply conservation, seawater treatment, water/sewage treatment, etc., to achieve full utilization of heat energy and low thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

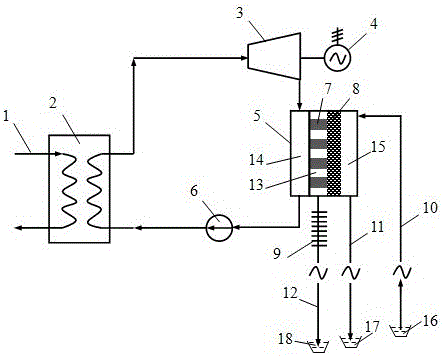

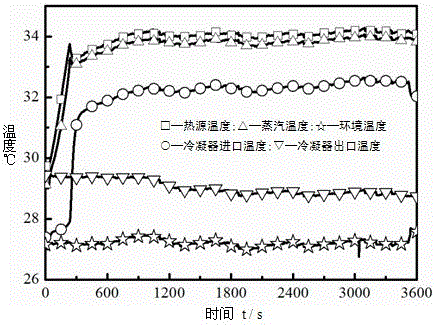

[0031] A set of porous media with an effective evaporation area of 50cm was developed in the laboratory 2 , The thermal conductive ribs and base and the evaporator shell are made of copper. The NaCl solution with a salt content of 17g / L is used to simulate "sea water", and the water-cooled condenser is used to condense fresh water vapor. Set the vertical height between the liquid level of the seawater storage tank and the brine storage tank and the top of the seawater chamber to be 9.5 meters and 10 meters respectively, and the vertical height between the liquid level of the fresh water storage tank and the condenser to be 10 meters. In the experiment, the electric heating rod was used to simulate the exhaust steam heat source at the outlet of the steam turbine, and the temperature of the heating rod, the temperature of seawater steam, the temperature of the inlet and outlet of the condenser and the ambient temperature were recorded by thermocouples.

[0032] In order to ach...

Embodiment 2

[0035] According to relevant data of "Exergy Analysis of R245fa Rankine Cycle Waste Heat Power Generation System" published by Luo Xianglong et al. in the Journal of Energy Saving Technology, the following working example of the system of the present invention is derived. When the steam waste heat in the factory is about 110°C, the steam flows into the heat exchanger to exchange heat with the working medium R245fa, and heats the R245fa into high-pressure steam. The high-pressure steam washes the turbine blades and drives the generator to generate electricity. At this time, the temperature of the steam is about 36°C after the steam turbine generates electricity, and the exhaust steam enters the seawater desalination evaporator, and exchanges heat with the seawater in the porous medium through the heat conduction fins to cool it into a liquid state, and the liquid R245fa is transported again under the action of the pump to the heat exchanger, and complete the entire low-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com