Treating method of high-salt waste water

A technology of high-salt wastewater and treatment method, which is applied in the fields of food industry wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. It is easy to float and drain and other problems, so as to achieve the effect of small footprint, lower operating costs, and easy enlargement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A treatment method for high-salt wastewater, comprising the following steps:

[0027] (1) Add 0.5-1% lye of the total weight of high-salt wastewater into the high-salt wastewater, stir evenly and then let it stand; the solution after standing is filtered through a hollow fiber ultrafiltration membrane; the lye is sodium carbonate solution , the massfraction of sodium carbonate solution red sodium carbonate is 60-70%;

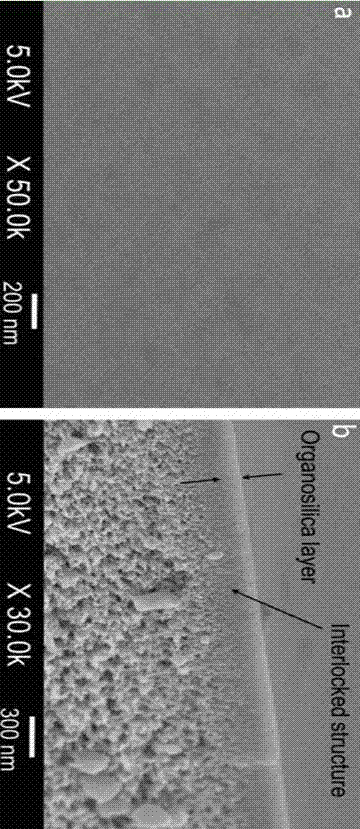

[0028] (2) The filtered solution is heated to 50-70°C, then pumped into the organosilicon membrane module by a pump, and then separated by the organosilicon membrane module to obtain concentrated aqueous solution and pure aqueous solution; the salt content in the concentrated aqueous solution is greater than or equal to 10%;

[0029] (3) The concentrated aqueous solution enters the evaporating device for the first evaporation, and the evaporated water vapor passes through the condensing device and then returns to the re-evaporating device for the second ...

Embodiment 2

[0033] The indicators of high-salt wastewater somewhere are as follows: pH is 2-3, conductivity is 5000-6000μS / cm, COD is 60-100mg / L, and salt content is 3%.

[0034] The processing method is as follows:

[0035] (1) Add lye with 1% of the total weight of high-salt wastewater into the high-salt wastewater, stir evenly and then let it stand; the solution after standing is filtered through a hollow fiber ultrafiltration membrane; the lye is sodium carbonate solution, carbonic acid The massfraction of sodium solution red sodium carbonate is 70%;

[0036] (2) The filtered solution is heated to 50-70°C, and then pumped into the organosilicon membrane module, and then separated by the organosilicon membrane module to obtain concentrated aqueous solution and pure aqueous solution; the salt content in the concentrated aqueous solution is 11 %;

[0037] (3) The concentrated aqueous solution enters the evaporating device for the first evaporation, and the evaporated water vapor passes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com