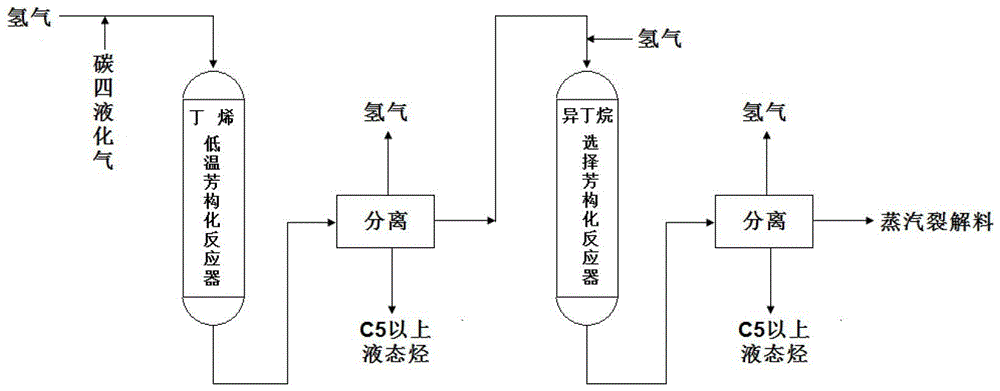

A two-stage reaction process for hydrogen aromatization of C4 liquefied petroleum gas

A technology of liquefied gas and aromatization, which is applied in hydrotreating process, petroleum industry, production of liquid hydrocarbon mixture, etc., can solve the problems of low positive-to-isolation ratio, lack of attractiveness, low ethylene propylene yield, etc., to ensure quality , increase flexibility, optimize the effect of gasoline quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Using the C4 liquefied gas produced by the catalytic cracking unit as the raw material, its composition is: isobutane: 26.24%, n-butane: 11.53%, n-isobutene: 29.54%, trans-butene-2: 18.60%, cis- Butene-2: 13.86%, carbon five (C 5 ): 0.23%. The positive-to-isotropic ratio of C4-alkanes in this feedstock is about 0.44. Load the aromatization catalyst SIHZSM-5(A)-12 prepared according to Example 10 of CN1586721A in the upstream butene low-temperature aromatization reactor, named DS-1, and select a temperature of 380°C and a reaction pressure of 3.0MPa , feed space velocity 2.0h -1 , the reaction condition of hydrogen oil ratio 500 (v / v). The output of the reactor is analyzed for mass balance, and the liquefied gas fractions (isobutane, n-butane and a small amount of unconverted butene, propane and a small amount of propylene produced by the reaction) are sent to the downstream isobutane selection Aromatization reactor, the aromatization catalyst SIHZSM-5(A)-07 prepared...

Embodiment 2

[0036] Repeat Example 1, but change the operating conditions of the upstream butene low-temperature aromatization reactor to a reaction temperature of 360°C, a reaction pressure of 2.0MPa, and a feed space velocity of 1.0h -1 , Hydrogen oil ratio 50 (v / v). Then the dry gas yield (methane, ethane, ethylene) of the upstream reactor is 1.2%, the liquefied gas yield is 58.2%, and C 5 The above liquid hydrocarbon yield is 40.6%. Among them, C 5 The content of aromatics in the above liquid hydrocarbons is 35.4%, the content of benzene is 0.7%, the content of olefins is 9.2%, and the rest are alkanes and naphthenes; the composition of isobutane-rich liquefied gas is propane 18.3%, isobutane 62.8%, n-butane 21.7%, total butene 5.19%, and the isotropic ratio of carbon tetraalkanes is about 0.35. The above-mentioned isobutane-rich liquefied gas is sent as a raw material to the downstream isobutane selective aromatization reactor. The operating conditions are: reaction temperature 460...

Embodiment 3

[0038] Repeat Example 1, but change the operating temperature of downstream isobutane selective aromatization reactor to 480°C, reaction pressure 1.0MPa, feed space velocity 4.0h -1 , Hydrogen oil ratio 200 (v / v). Then the product distribution of the isobutane-rich liquefied gas in the upstream reactor reacted in the downstream reactor is: dry gas 6.1%, propane 31.0%, propylene 0.1%, isobutane 15.9%, n-butane 21.5%, total butane ene 0.2%, C 5 The above liquid hydrocarbon yield is 25.2%. Among them, C 5 The content of aromatics in the above liquid hydrocarbons is 92.6%, and the positive-to-isotropic ratio of C4-alkanes in the isobutane-depleted liquefied gas rises to about 1.35. It can be seen that the operating temperature of the downstream reactor is an effective means to adjust the positive and negative ratio of C4 alkanes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com