Asymmetric metal filter core and preparation method thereof

A metal filter element, asymmetric technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of difficulty in filter element preparation, unclear gradient structure, and few preparation methods involved, and achieve good application prospects. Long service life and excellent regeneration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

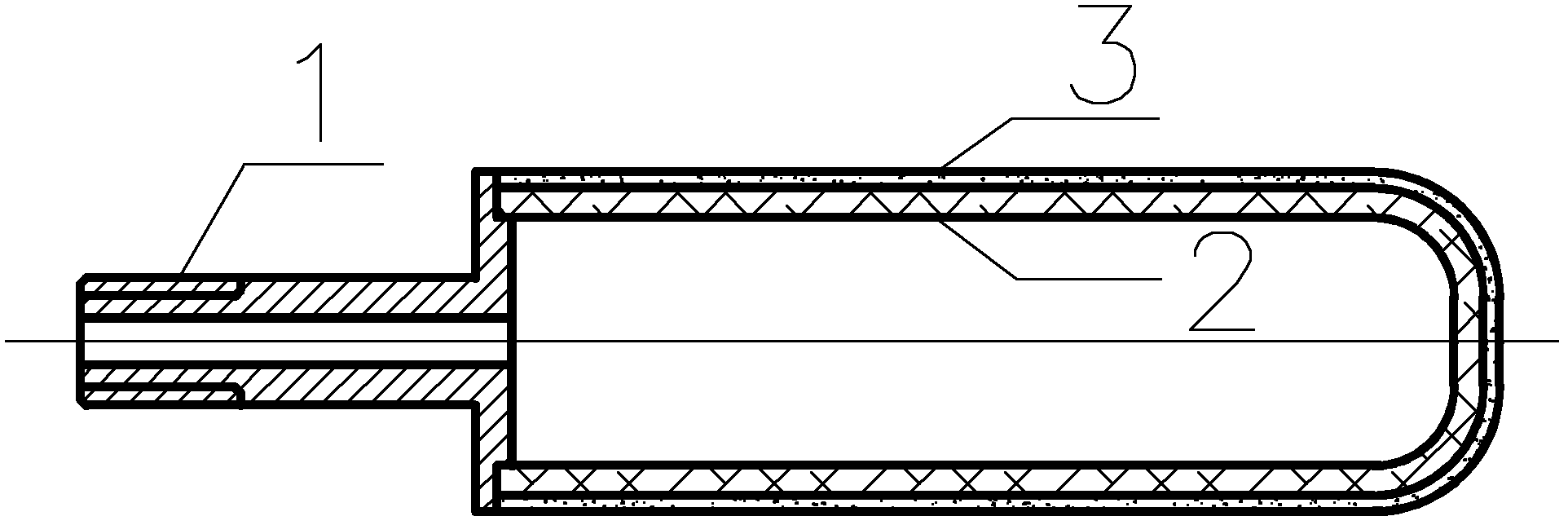

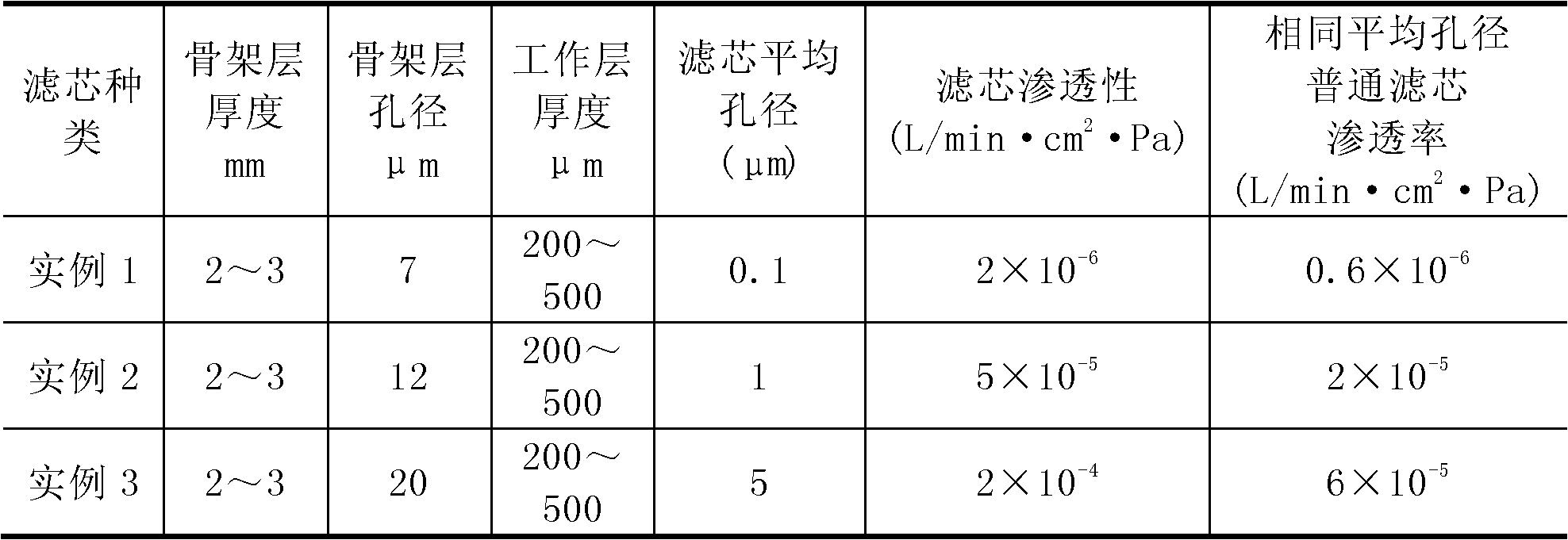

[0027] The structure of the asymmetric metal powder filter element formed by powder composite sintering of the present invention is as follows figure 1 As shown, the powder filter element is formed by composite sintering of a framework layer 2 with a larger pore size and higher permeability and a working layer 3 with a smaller pore size. Skeleton layer 2 is Shape, that is, one end has a tube bottom and one end is open. In addition, the open end of the framework layer 2 is welded with a connector 1 (the connector can be any one of a threaded joint, a straight pipe, a venturi or a Raoul throat), and the filter element size of the framework layer 2 is d×l ×δ=φ(30~100)×(100~2000)×(1.2~5)mm, the average pore diameter is 5~35um (according to the inventor’s experience, it can be compounded into 0.1μm based on the 5μm framework layer pores The asymmetric filter element can be compounded into a 10 μm asymmetric filter element on the basis of 35 μm pores. The composite filter element h...

Embodiment 1

[0050] The framework layer filter element is prepared by isostatic pressing process. According to the structure of the frame layer filter element, the corresponding tubular mold is designed. The 316L stainless steel metal powder raw material is sieved and graded with a particle size of -150+250 mesh; filled in the corresponding tubular mold, vibrated on the vibrating table, and then directly formed by a cold isostatic press, the forming pressure is 200MPa, and the The pressing time is 10 minutes; a vacuum high-temperature sintering furnace is used to sinter the demolded green body. The sintering temperature is 1250℃, the holding time is 2 hours, and the vacuum degree is -1 Pa. After the sintering is completed, the joint is welded, the welding current is 50A, the welding speed is 8mm / min, and the prepared framework layer filter element is φ60×1000mm.

[0051] The particle size of the working layer powder is 0.1um. Add 2% binder and 2 times diluent to the powder material of a cert...

Embodiment 2

[0053] The framework layer filter element is prepared by isostatic pressing process. According to the structure of the frame layer filter element, the corresponding tubular mold is designed. The 316L stainless steel metal powder raw material is sieved and graded with a particle size of -100+200 mesh; filled in the corresponding tubular mold, vibrated on the vibrating table, and then directly formed by a cold isostatic press, the forming pressure is 200 MPa, and the The pressing time is 10min; a vacuum high-temperature sintering furnace is used to sinter the demoulded green body, the sintering temperature is 1260℃, the holding time is 2 hours, and the vacuum degree is -1 Pa. After the sintering is completed, the joint and the tube bottom are welded, the welding current is 50A, the welding speed is 8mm / min, and the prepared framework layer filter element is φ60×1000mm.

[0054] The particle size of the working layer powder is 5um. Add 4% binder and 2 times diluent to a certain par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com