Method for recycling impurity salts generated in industrial wastewater treatment

A technology for industrial wastewater and resource utilization, which is applied in the purification of alkali metal halides, calcium/strontium/barium sulfate, calcium carbonate/strontium/barium, etc. , low content of sodium sulfate, etc., to achieve the effect of wide operating conditions, high recovery rate and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This example is used to illustrate the resource recovery method of miscellaneous salts produced in industrial wastewater of the present invention.

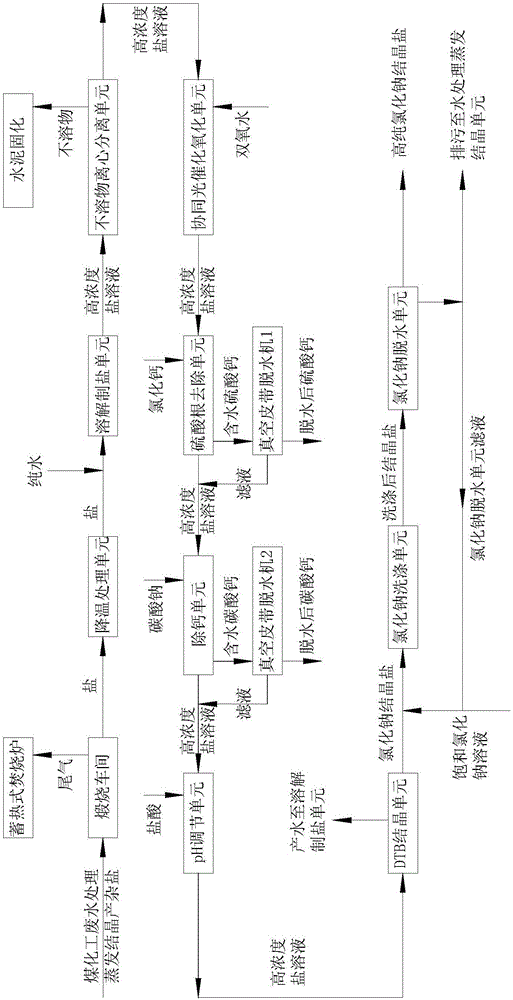

[0032] like figure 1 As shown in the schematic diagram of the process flow, the main process units used to implement the method include three-effect evaporation and crystallization unit for industrial wastewater treatment, calcination workshop, cooling treatment unit, dissolution salt production unit, centrifugal separation unit for insoluble matter, and coordinated photocatalytic oxidation. Unit, sulfate removal unit, calcium removal unit, pH adjustment unit, DTB crystallization unit, sodium chloride washing unit, sodium chloride dehydration unit.

[0033]Among them, the tail gas of the calcination workshop is discharged after being treated by the regenerative incinerator; the dissolution salt production unit includes crushing, water addition, and stirring measures in sequence; the insoluble impurity produced by the insolu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com