Liquid injection machine and liquid injection units thereof

A liquid injection machine and liquid injection technology, applied in the field of liquid injection machines, can solve the problems of low liquid injection efficiency, at most ten or twenty, expensive, and cheap ones costing several thousand yuan per unit, etc. The effect of reducing the cost of liquid injection and improving the efficiency of liquid injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

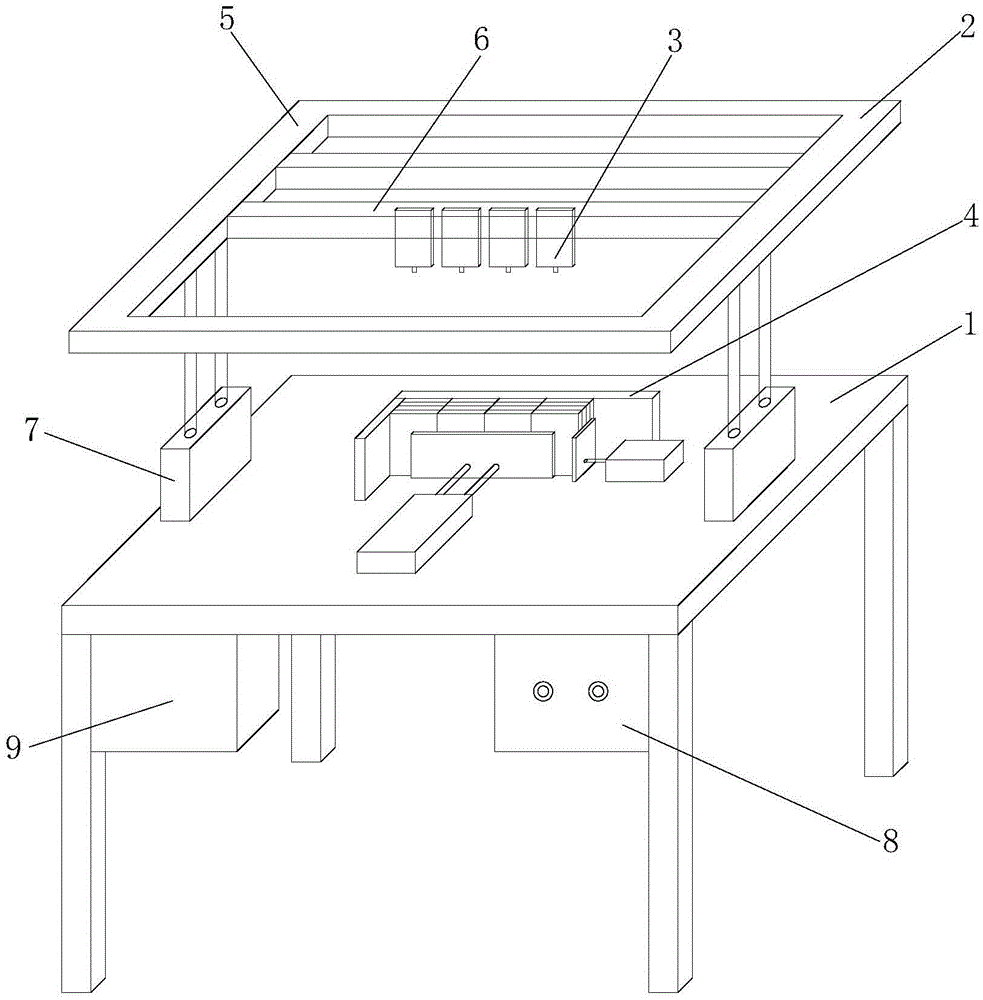

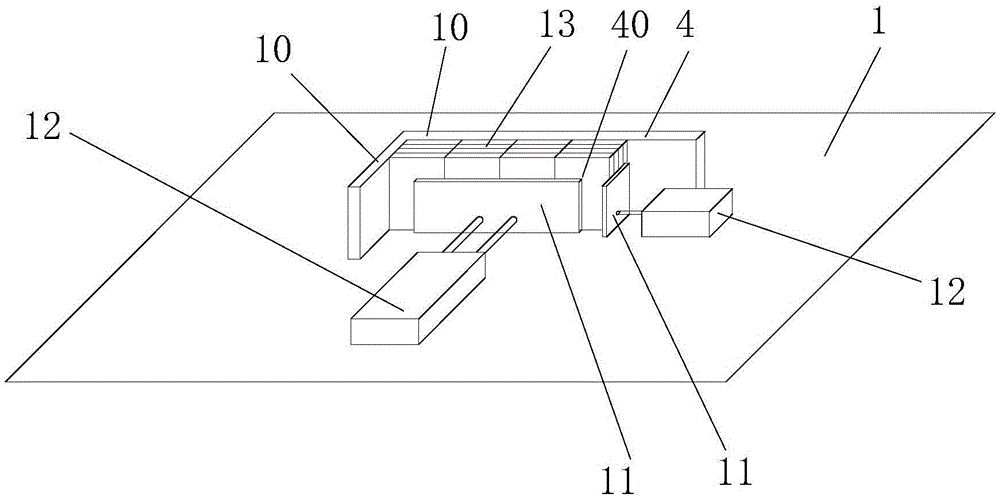

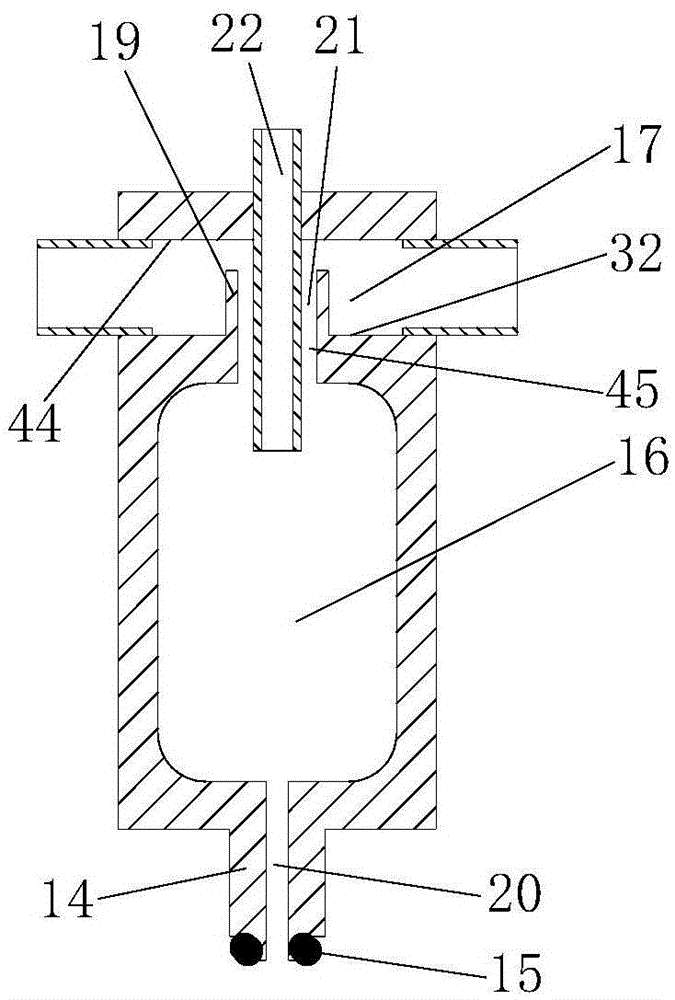

[0034] Such as Figure 1 to Figure 8 As shown, the liquid injection machine in this embodiment includes an electrical control box 8 , a machine platform 1 , a lifting device 2 , a liquid injection unit 3 , a cell positioning jig 4 and a solenoid valve group 9 .

[0035] Such as figure 1 As shown, the lifting device 2 includes a frame 5 , a beam 6 and a lifting cylinder 7 . The 7 sleeve ends of the lifting cylinder are vertically fixed on the plane of the machine platform 1, the 7 shaft ends of the lifting cylinder are fixed with the frame 5 and drive the frame 5 to move up and down, and the cross beam 6 is fixed on the frame 5 and its position can be adjusted. The liquid injection unit 3 is fixed on the beam 6 and its position can be adjusted up, down, left, and right. Both the positions of the crossbeam 6 and the liquid inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com