Syringe capable of preventing needle from falling off

A syringe and anti-dropping technology, which is applied in the field of syringes, can solve the problems such as the needle dropping or breaking of the syringe, the inability to normally complete the injection of medicine liquid for sick animals and poultry, the dropping or breaking of the needle, etc., so as to reduce the injection cost and reduce the Syringe volume or length, the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

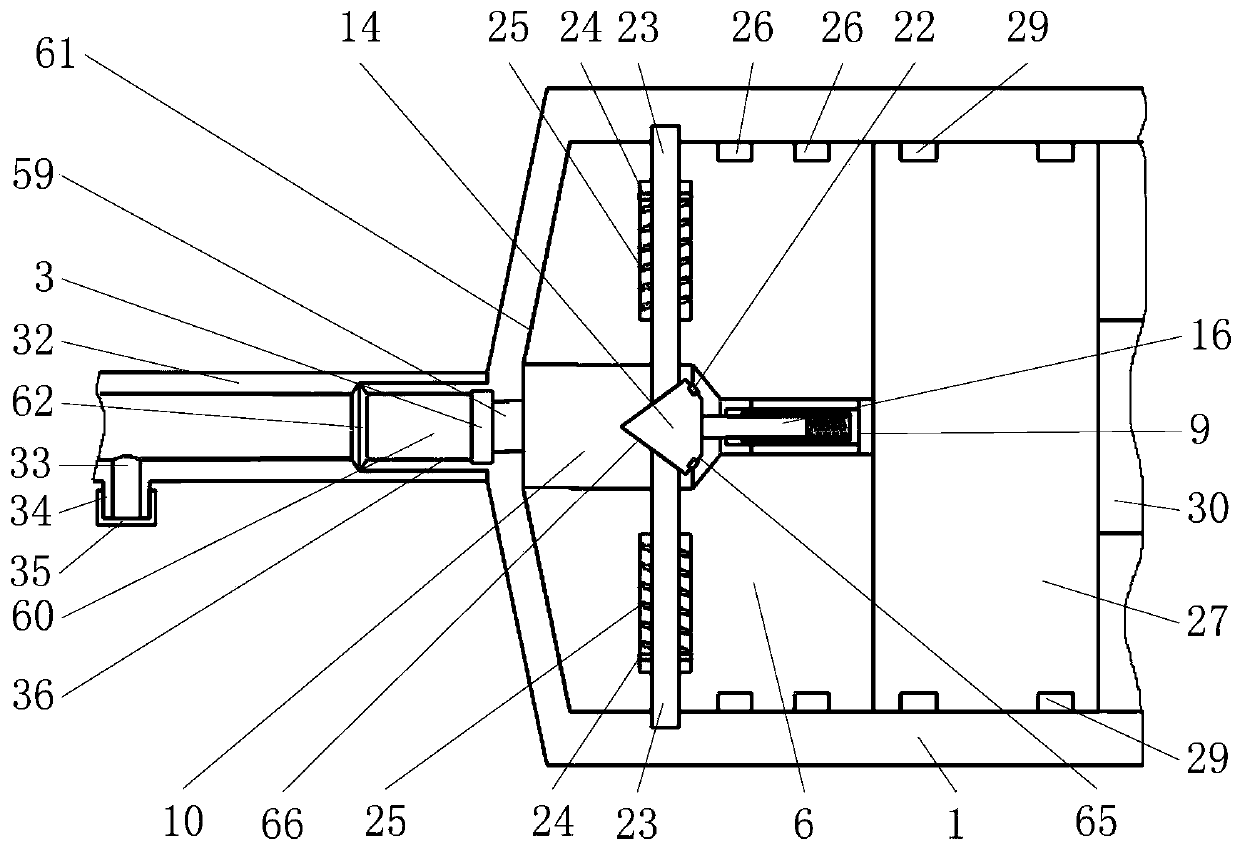

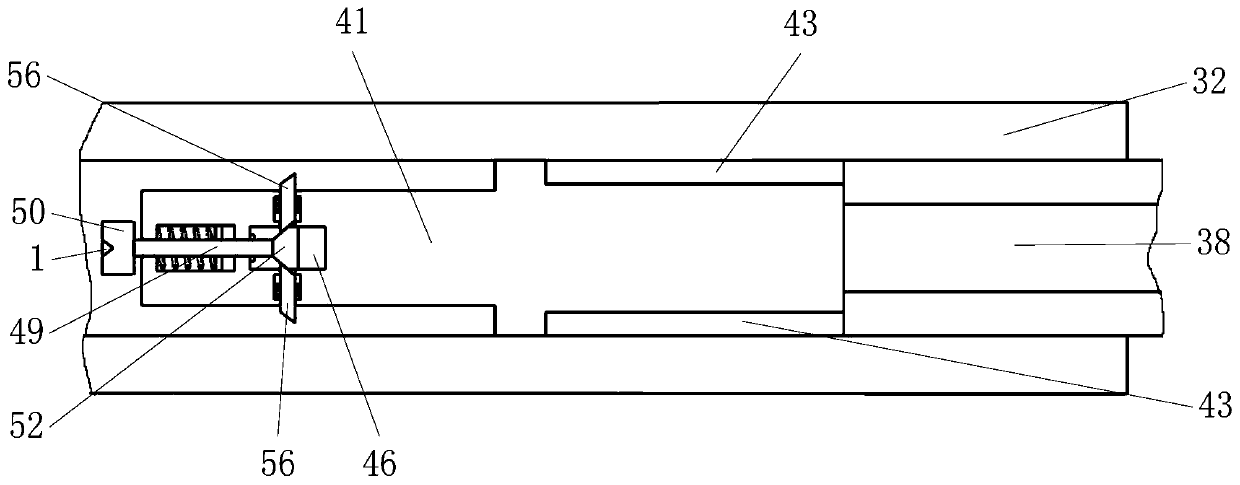

[0034] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

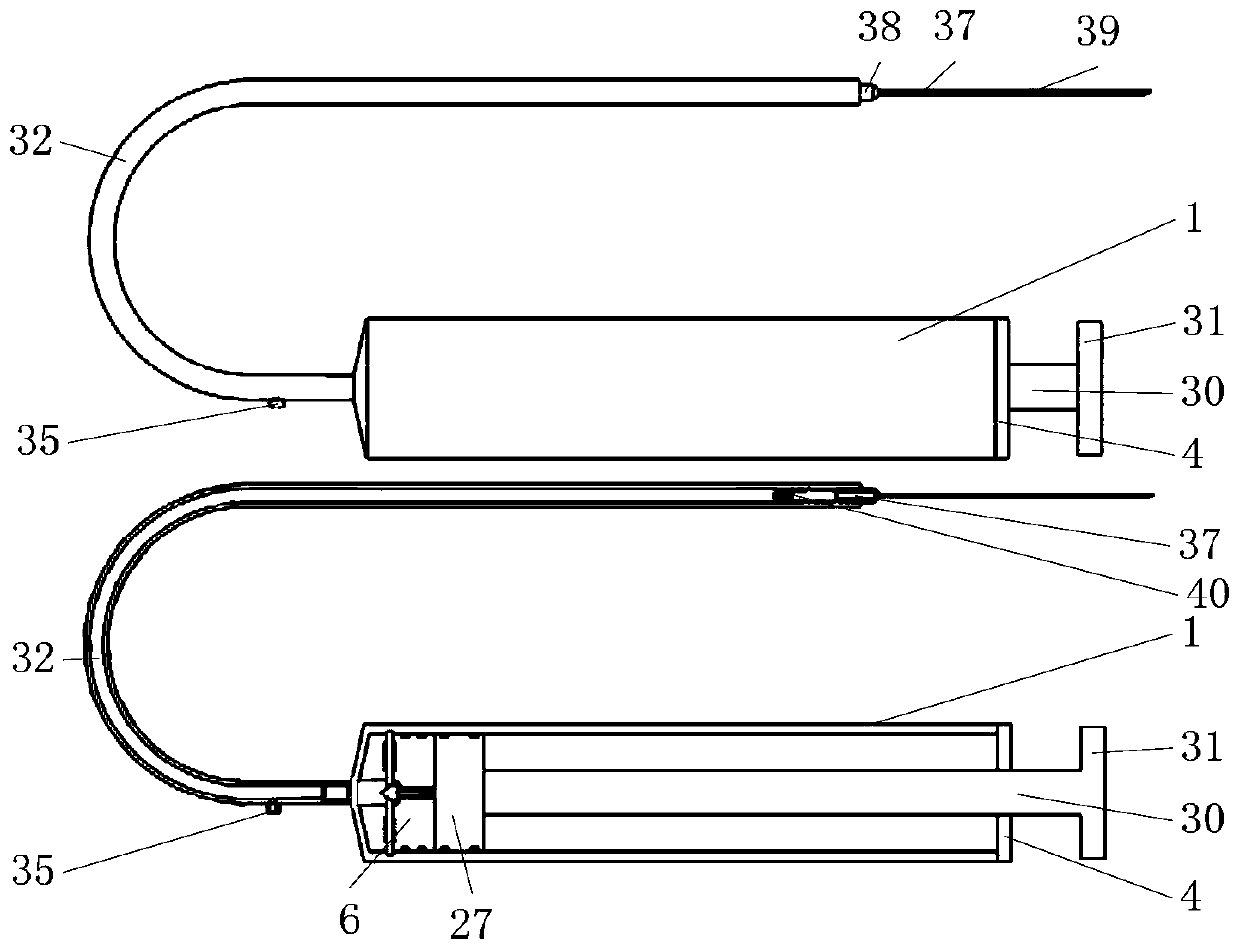

[0035] Such as figure 1 , 4 As shown, it includes a syringe 1 with an injection head 36, a piston mechanism 5, a cylindrical piston A27, an injection rod 30, a hose 32, a needle structure 37 composed of a needle cover 38 and a needle tube 39, and a slide mechanism 40, wherein Such as figure 1 As shown, the injection head 36 on the syringe 1 is connected with the needle cover 38 of the needle structure 37 through the flexible pipe 32; figure 1 , 2 As shown, the piston mechanism 5 and the manually driven piston A27 are sealed and slid inside the syringe 1, and the piston mechanism 5 is located between the injection hole 59 and the piston A27; 32 and injection head 36. Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com