Method and Well Pattern Structure of Solvent Improving Heavy Oil Reservoir Recovery by Steam-Assisted Gravity Drainage

An auxiliary gravity and steam technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of accelerated steam chamber drainage speed, large reserve loss, and uniform development of interlayers without steam chamber breakthrough, achieving Effects of enhancing oil recovery, promoting connectivity, and promoting the development of steam chambers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

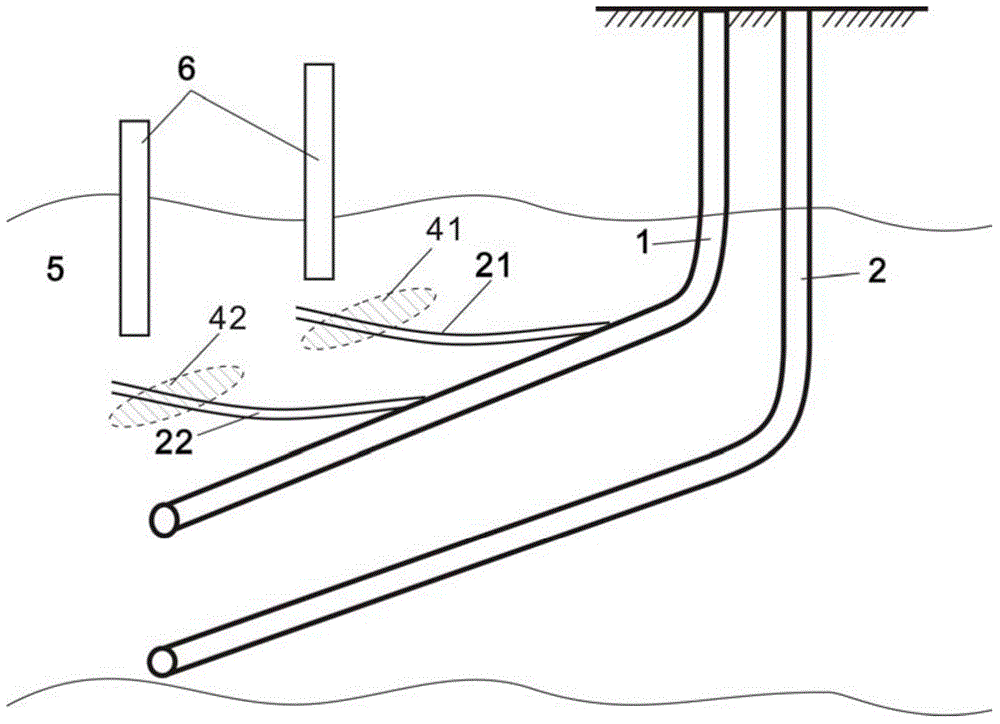

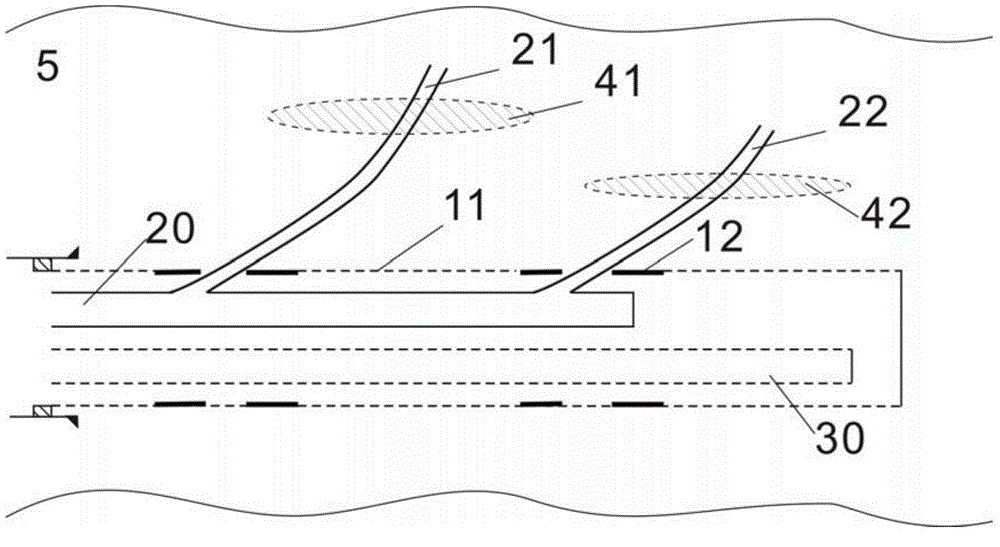

[0053] Such as figure 1 As shown, this embodiment provides a solvent-improved steam-assisted gravity drainage method for recovering heavy oil reservoirs. Interlayers 41 and 42 are developed directly above the steam injection wells of the main oil layer 5 of the heavy oil reservoir, wherein the interlayers 41 have a continuous thickness 2 meters, 30 meters in length along the horizontal section, 15 meters in width along the horizontal section, and a permeability of 25 mD; The rate is 40 mD, and the distance from the top of the interlayer 41 and 42 to the top boundary of the oil layer is 2 meters and 5 meters respectively; the effective average thickness of the oil layer 5 is 15 m.

[0054] The solvent-improved steam-assisted gravity drainage recovery method for heavy oil reservoirs provided in this embodiment includes the following specific steps:

[0055] (1) Determine the branch well intervals; according to the interlayer identification results, determine the number of branc...

Embodiment 2

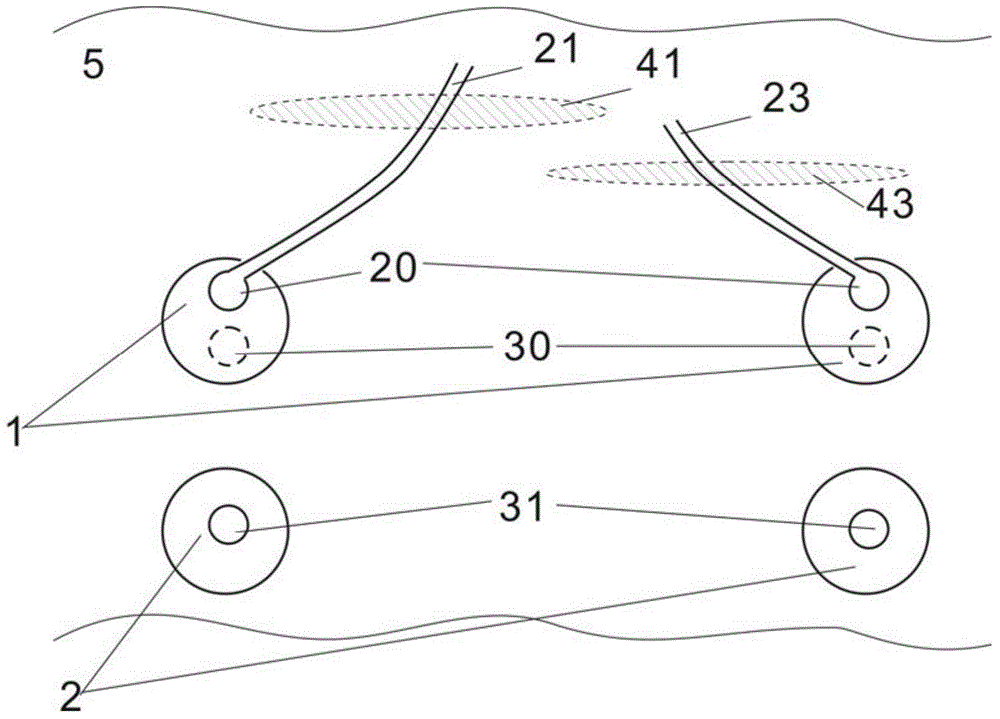

[0062] This embodiment provides a method for improving steam-assisted gravity drainage recovery of heavy oil reservoirs by solvent, such as image 3 As shown, interlayers 41 and 43 are developed in the upper oil layer 5 in the middle of two adjacent SAGD well pairs in the main oil layer of this heavy oil reservoir, wherein the interlayer 41 has a continuous thickness of 2.5 meters, a length of 40 meters along the horizontal section, and a width of 40 meters along the horizontal section. The interlayer 43 has a continuous thickness of 1.9 meters, a length of 33 meters along the horizontal section, a width of 15 meters along the horizontal section, and a permeability of 20 millidarcy. The tops of the interlayers 41 and 43 are respectively 4 meters and 6 meters; the effective average thickness of the oil layer 5 is 18m.

[0063] The solvent-improved steam-assisted gravity drainage recovery method for heavy oil reservoirs provided in this embodiment includes the following specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com