Novel plastic processing method for high-performance magnesium alloy seamless long pipe material

A technology for plastic processing and magnesium alloys, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of poor mechanical properties, significant texture characteristics and low processing efficiency of magnesium alloy pipes, and achieve mechanical properties improvement, The effect of reducing the probability of cracking and reducing tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

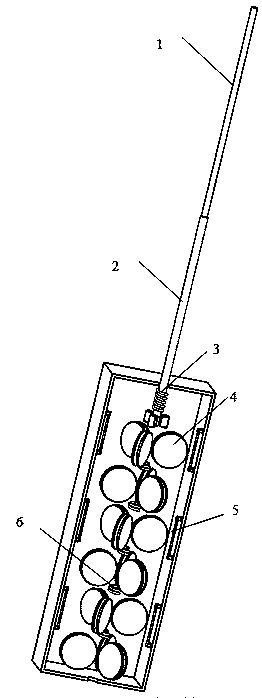

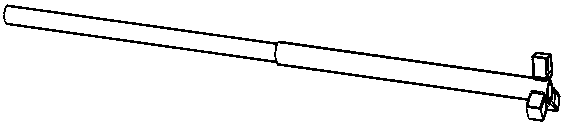

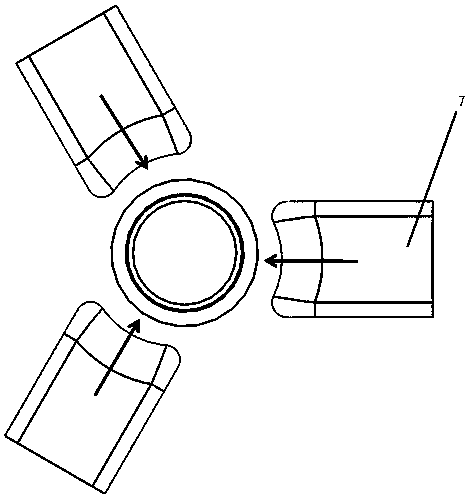

Embodiment 1

[0029] The billet used is a cast commercial AZ31 magnesium alloy tube billet, the original size specification is: outer diameter φ51mm, wall thickness 8mm, length 3000mm. The outer diameter of the mandrel used is φ40mm, the outer diameter of the stepped section is φ37mm, and the mandrel is coated with graphite emulsion lubricant. The preheating temperature of the roll is 250°C, the tube blank is heated to 350°C by the heating induction coil, and the mandrel is preheated to 280°C at the same time, and then the shrinking pliers are loaded from three directions at the same time for shrinking. After that, the induction coil works at the speed of heating 350°C per second. At the same time, the mandrel pushes the tube billet to feed at a speed of 1.2m / s. The sub-unilateral reductions are 2mm and 1.5mm, respectively, to obtain a capillary tube with an outer diameter of 44mm and a wall thickness of 2mm. After that, the mandrel is taken out (no need to remove the rod), and a high-plast...

Embodiment 2

[0032] The blank used is an extruded commercial AZ31 magnesium alloy tube blank, and the original size specification is: outer diameter φ90×wall thickness 16mm×length 2500mm. The inner diameter of the mandrel used is φ58mm, and the diameter of the stepped section is φ50mm. After 5 passes of rolling, the unilateral reductions of each pass are: 4mm, 2.5mm, 1.5mm, 1.5mm, 0.5mm; the rod is removed by the stripping machine, and the outer diameter φ70×wall thickness is obtained after cutting to length 6mm×length 7500mm pipe; the roll preheating temperature is 280°C, the necking temperature is 380°C, the unilateral reduction of the jaw is 5mm, the mandrel preheating temperature is 250°C, and the surface of the mandrel is coated with MOS 2 Emulsion lubricant; during the rolling process, the heating rate of the induction coil is: 350°C / s, and the axial feeding speed is 0.85m / s.

[0033] The mechanical properties of the rolled pipe in this embodiment are as follows: the tensile strengt...

Embodiment 3

[0035] The blank used is the cast AZ61 magnesium alloy tube blank, the original size is: outer diameter 146mm x wall thickness 20mm x length 2000mm, the inner diameter of the mandrel used is φ105mm, and the diameter of the stepped section is φ96mm. After 4 passes of rolling, the unilateral reductions of each pass are: 3mm, 2.5mm, 2mm, 0.5mm, the shrinkage temperature is 300°C, the unilateral reduction is 8mm, and the temperature of the induction coil is adjusted to 250°C , the axial propulsion speed of the mandrel is 0.5m / s. The preheating temperature of the mandrel is 250°C, and the preheating temperature of the mandrel is 280°C. The surface of the mandrel is coated with MOS 2 Emulsion lubricant; after stripping and measuring to length, a pipe with outer diameter φ121×wall thickness 8mm×length 5500mm is finally obtained.

[0036] The mechanical properties of the rolled pipe in this embodiment are as follows: the tensile strength is 285Mpa-317Mpa, and the elongation after frac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com